Thermopile characteristic property contravariant method in controlling thermoelectric refrigeration

A technology of thermoelectric cooling and thermopile, which is applied in the directions of refrigerators, refrigeration and liquefaction, and machine operation modes, etc., can solve the problems of low efficiency and high energy consumption, and achieves reduced energy consumption, improved energy efficiency ratio, and full-load operation. effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

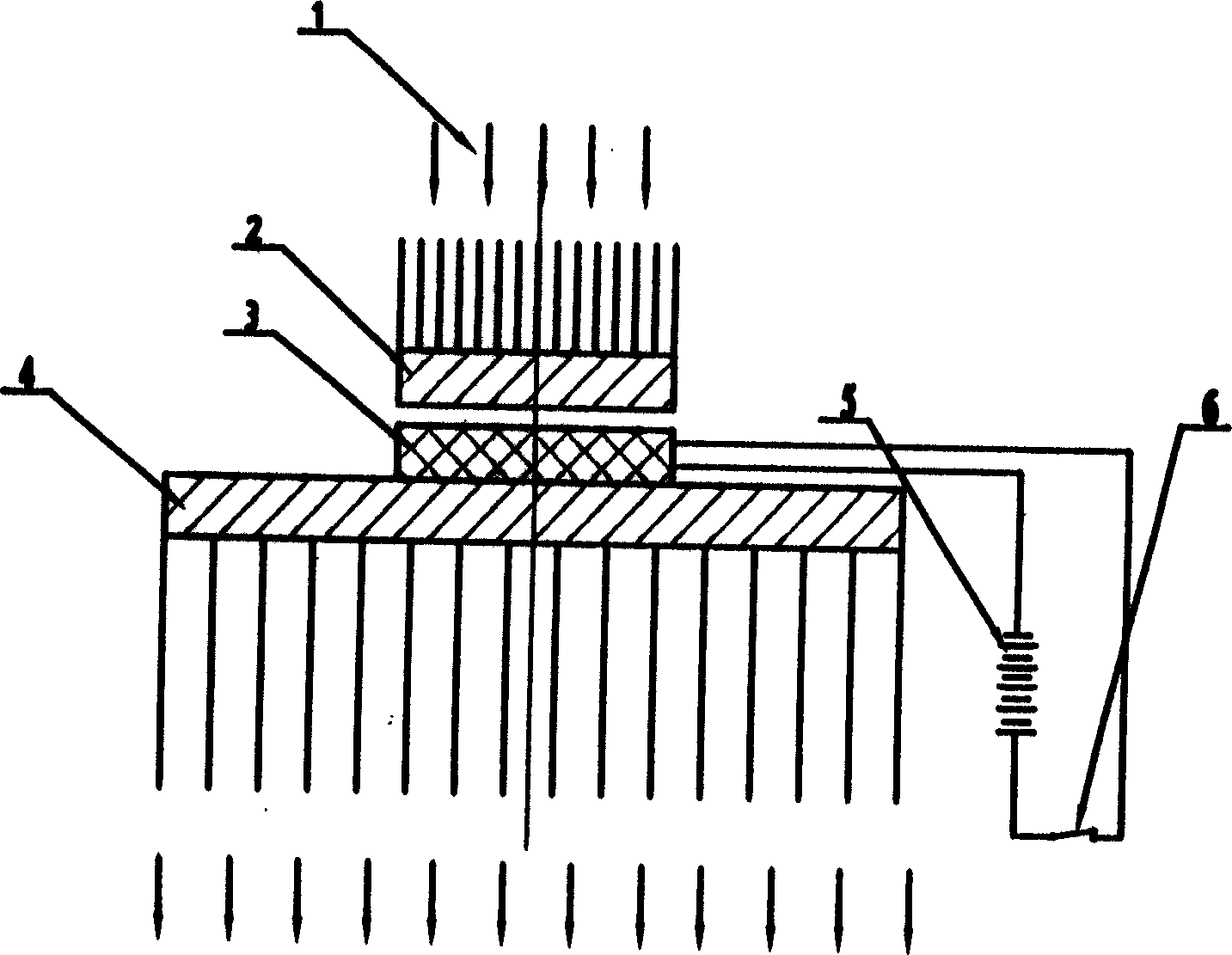

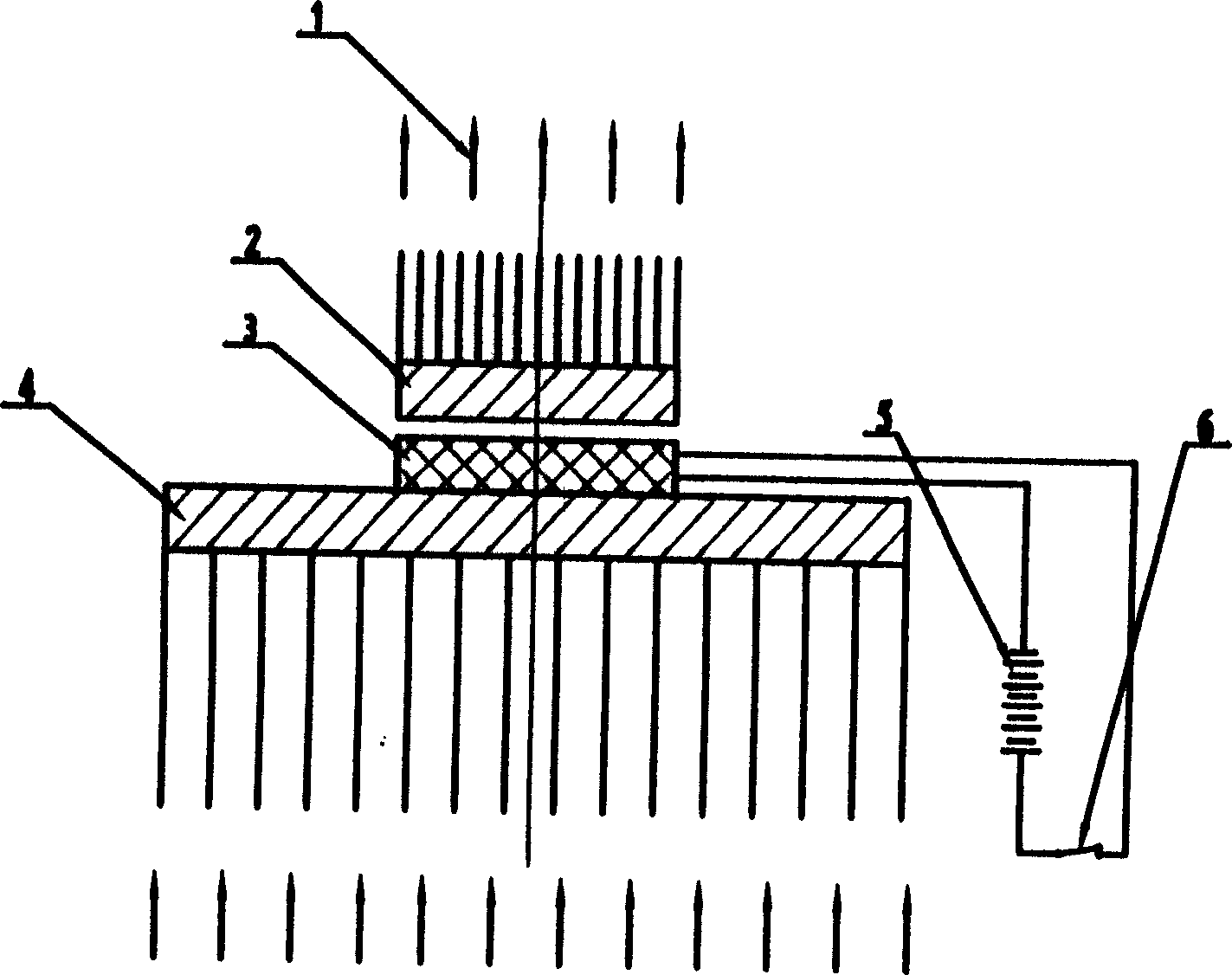

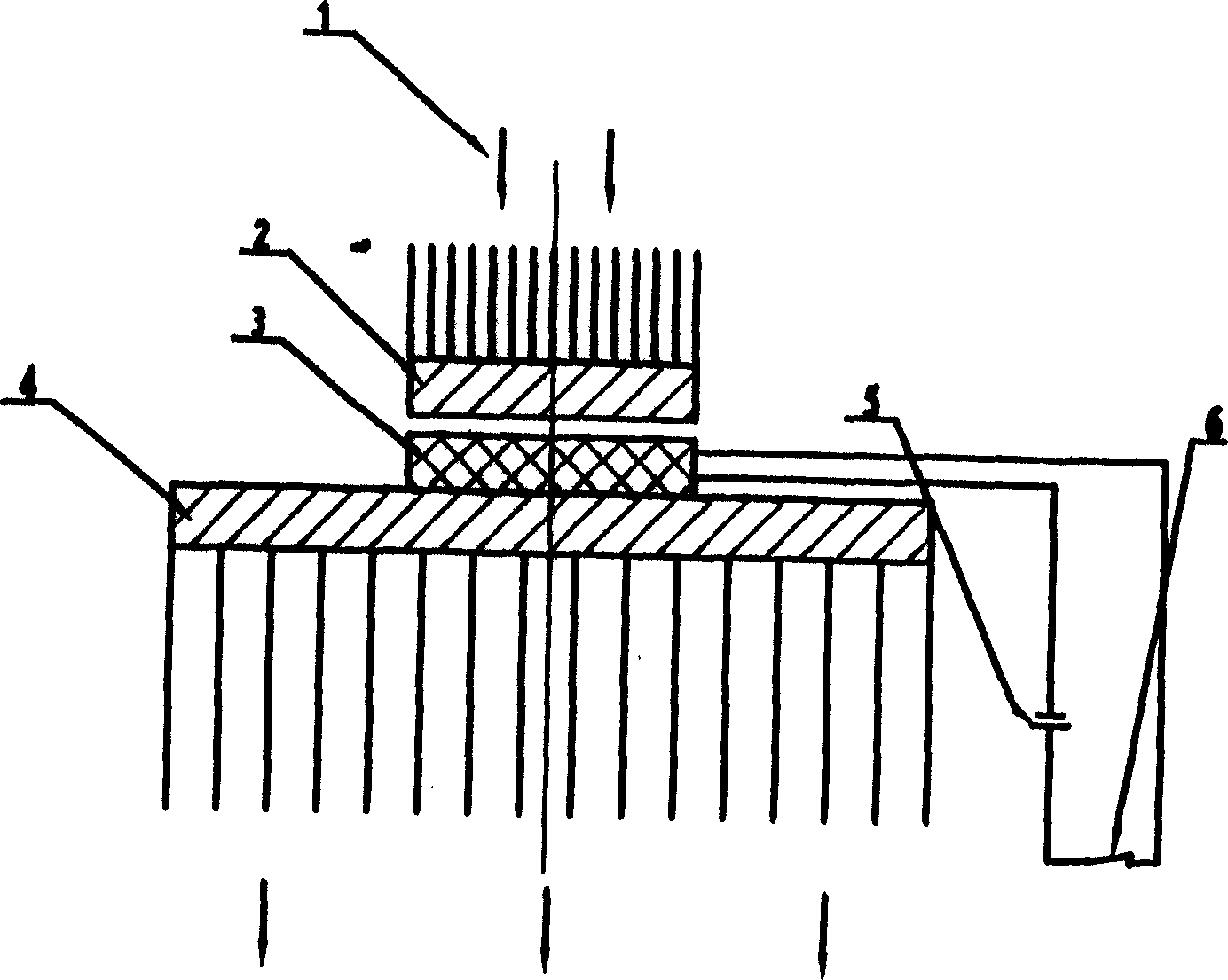

[0024] In the figure, 1 is the direction of the heat source, 2 is the condenser, 3 is the thermopile, 4 is the evaporator, 5 is the power supply, and 6 is the switch.

[0025] The method used in this embodiment to control the inversion of thermopile characteristics in thermoelectric cooling is to simultaneously provide a critical operating voltage slightly greater than the zero operating point for the thermopile after the specific environmental range reaches the preset temperature standard and shut down, so that The thermopile continues to be in a micro-working state, and the operating voltage at its critical point should generally be 25 to 35% of the rated operating voltage of the thermopile.

[0026] There are many ways to provide a critical operating voltage slightly greater than the zero operating point for the critical point of the thermopile, such as: switching power supply to adjust the operating frequency of the switching tube, changing the duty cycle; SCR control to ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com