Ground-support-free continous rigid frame bridge sidespan closure method

A technology of no landing, rigid frame bridge, applied in the field of bridge construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

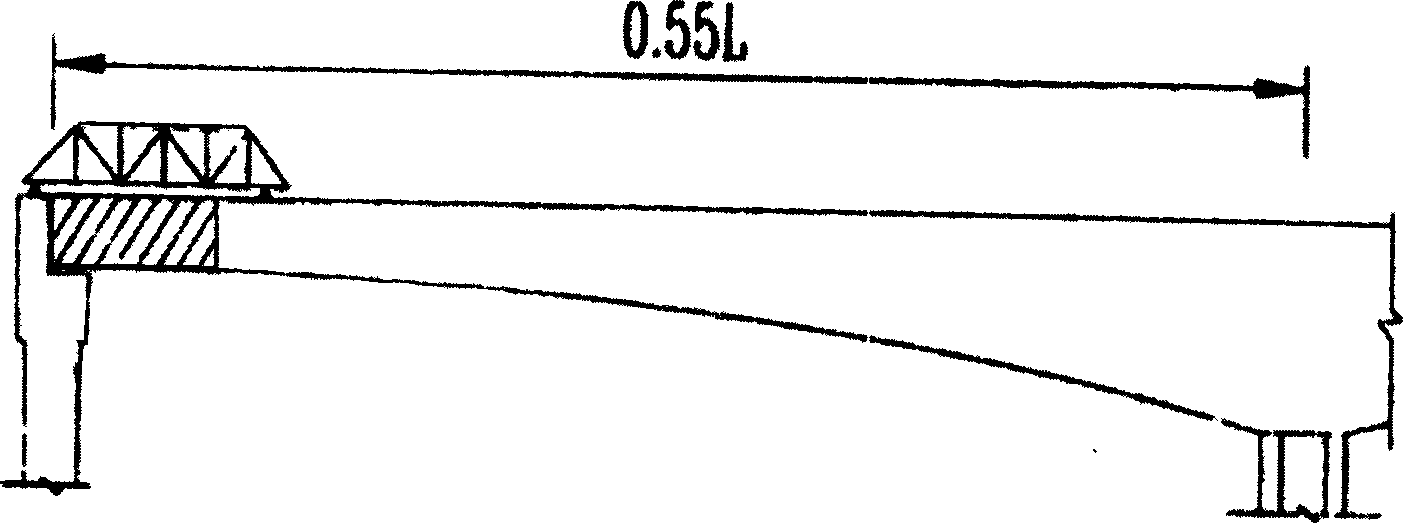

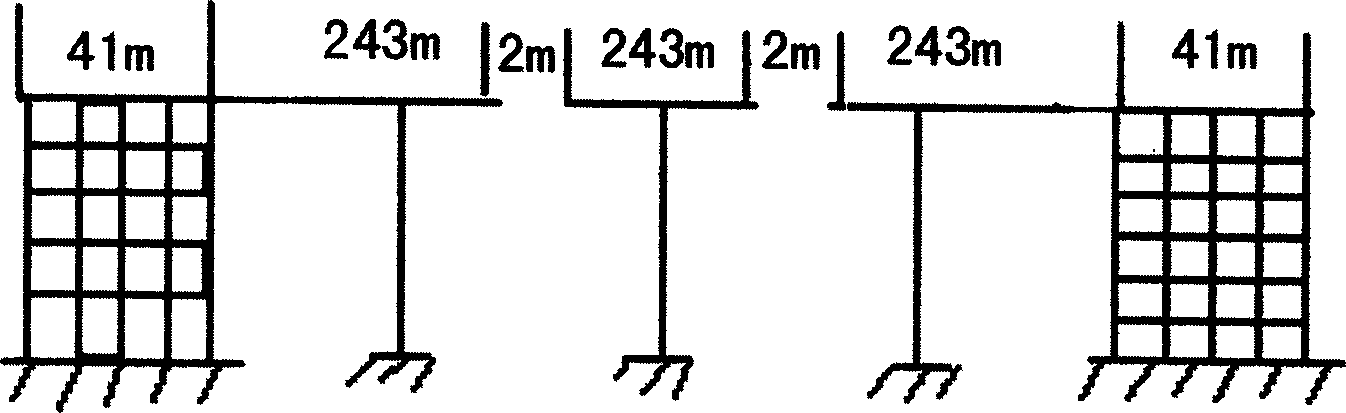

[0013] Such as Figure 1A , the original design is a continuous rigid frame bridge of 65+2×100+65m, which is closed with side spans and ground supports, and is now changed to 59+2×106+59m, with a side span / middle span ratio of 0.557, which belongs to the side span The minimum side-span / middle-span ratio of the pier without negative reaction force is in the range of 0.54 to 0.56, and the length of the side-span closing section is 7m, which can be closed with hanging blue cast-in-place. The steps are:

[0014] Select the side span / middle span ratio as 0.557, lay out the span according to the hydrogeological conditions of the river, and draw up the section;

[0015] Use a mature analysis program for design and analysis, and select a suitable section when the side-span fulcrum has the positive and negative force of the fulcrum that meets the requirements of the technical specification under any load;

[0016] Arrange ordinary steel bars and prestressed bars according to the inte...

Embodiment 2

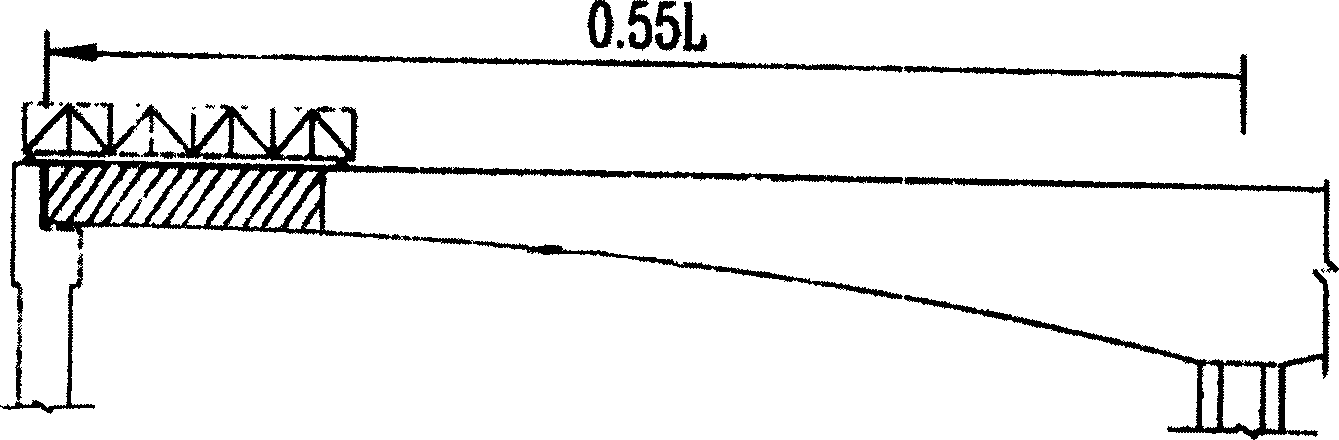

[0022] Such as Figure 1B , a bridge with a designed side span of 150m and a mid-span of 270m has a side-span / middle-span ratio of 0.556, which falls within the range of the minimum side-span / middle-span ratio of 0.54 to 0.56 for the side pier without negative reaction force. In this way, after the 16m side span closing section of the guide beam is cast in-situ, no matter where the live load is placed, there will be no negative reaction force at the fulcrum of the side pier and a certain reserve pressure will remain; 1 / 2 of the guide beam is applied to the cantilever And when the self-weight of the 16m cast-in-place section, the construction does not need additional cables, so that the guide beam method can be safely used to pour the cast-in-place box girder with a side span of 16m. Only when the foundation construction of the full hall support has been completed, the cast-in-place closure on the full hall support is used, such as: 14m is cast-in-situ on the support section, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com