Confocal raman cell

A confocal and lens technology, applied in instruments, optics, lenses, etc., can solve the problem of low Raman conversion efficiency, and achieve the effect of improving Raman conversion efficiency, compact structure, and high Raman conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

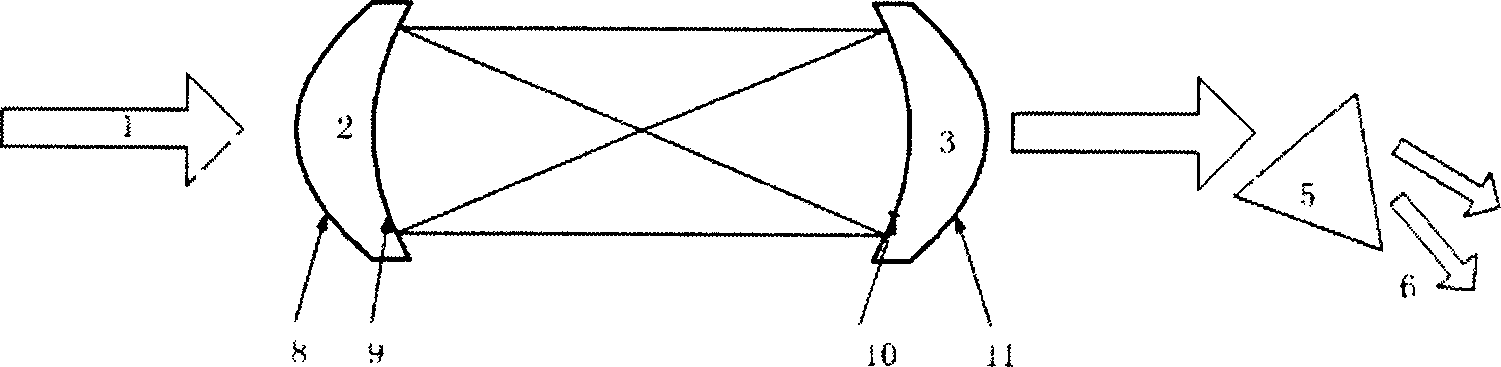

[0009] see now figure 1 , figure 1 It is a schematic structural diagram of an embodiment of the confocal Raman cell of the present invention. As can be seen from the figure, the confocal Raman cell of the present invention, the input window and the output window of the Raman cell are formed by the entrance lens 2 and the exit lens 3 directly installed at the two ends of the Raman cell. The lens 3 is a concave-convex lens composed of concave surfaces 9, 10 and convex surfaces 8, 11 with different radii of curvature. The concave surfaces 9, 10 form a confocal system relatively. The concave surface 10 of the exit lens 3 is coated with a dichroic film that is highly reflective to the pump light wavelength and anti-reflective to the Raman light wavelength.

[0010] The parallel incident pump light 1 is focused by the incident lens 2 and output 4 as parallel light at the exit lens 3, and then split by the prism 5 to obtain laser light with pump light wavelength 6 and Raman wavelen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com