Stator for a turbomachine

A turbine and stator technology, applied in gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of pressure chamber temperature increase, air leakage collection, increase efficiency loss of stator cooling system, etc., to reduce manufacturing cost, reduce load, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

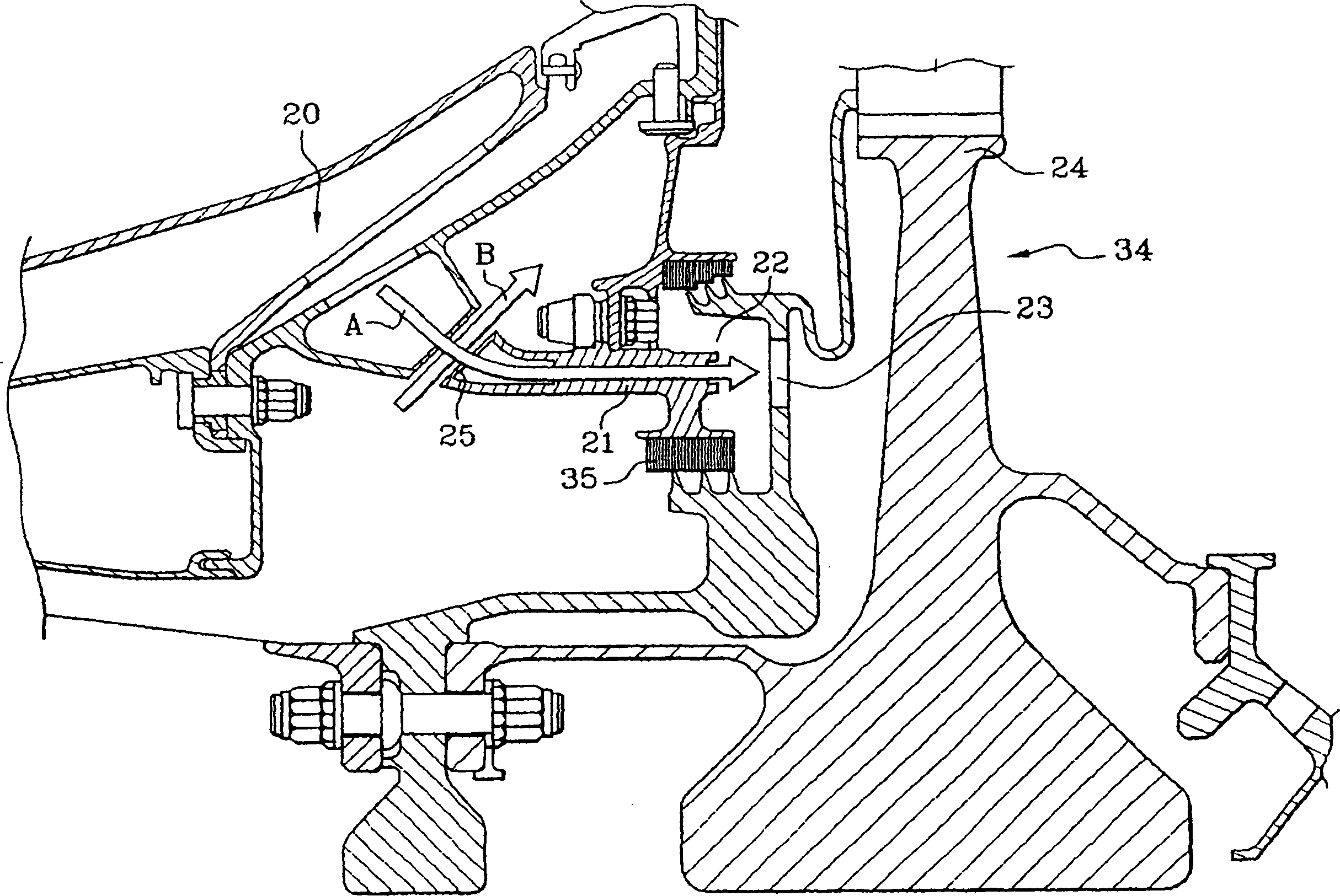

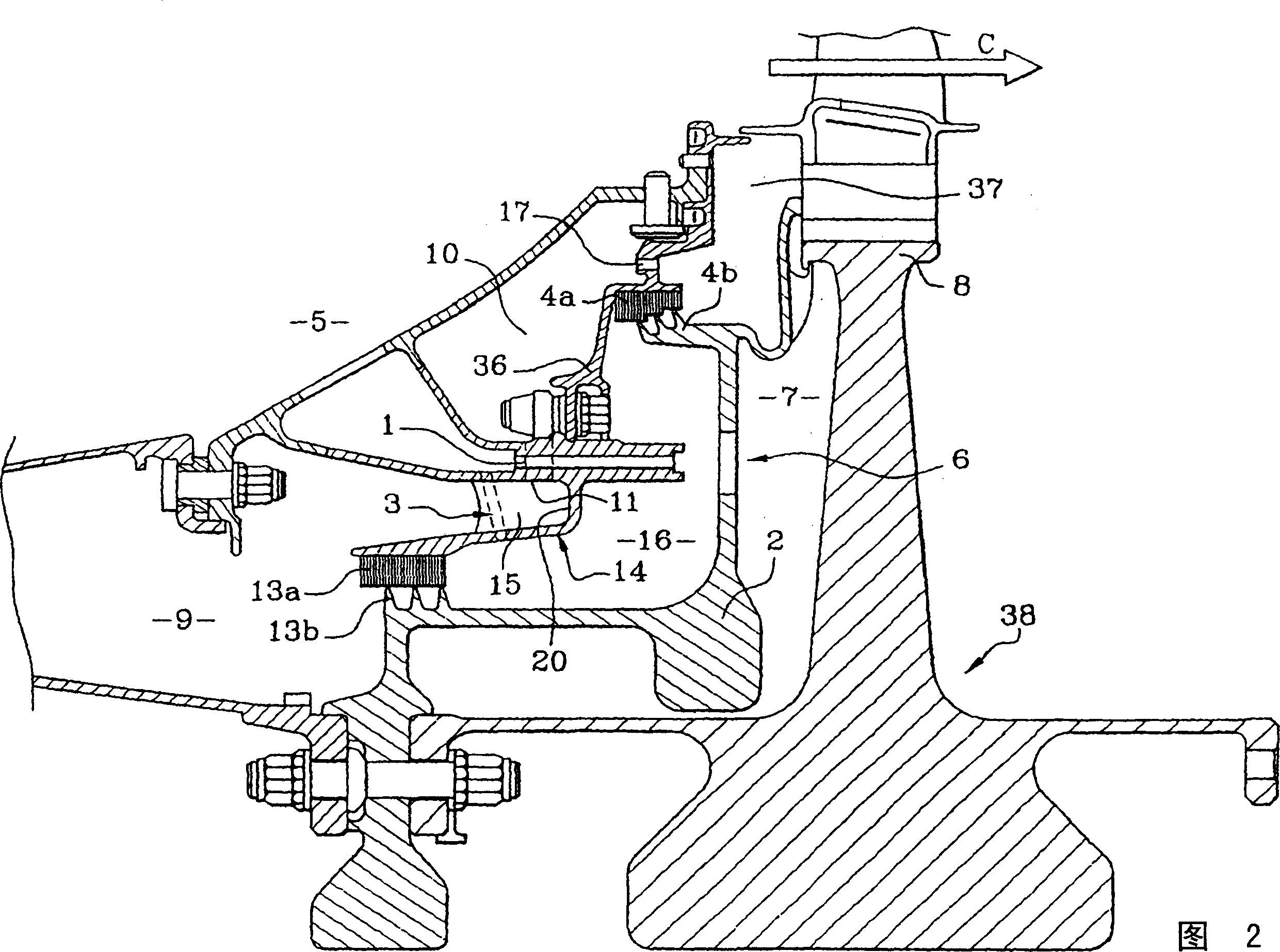

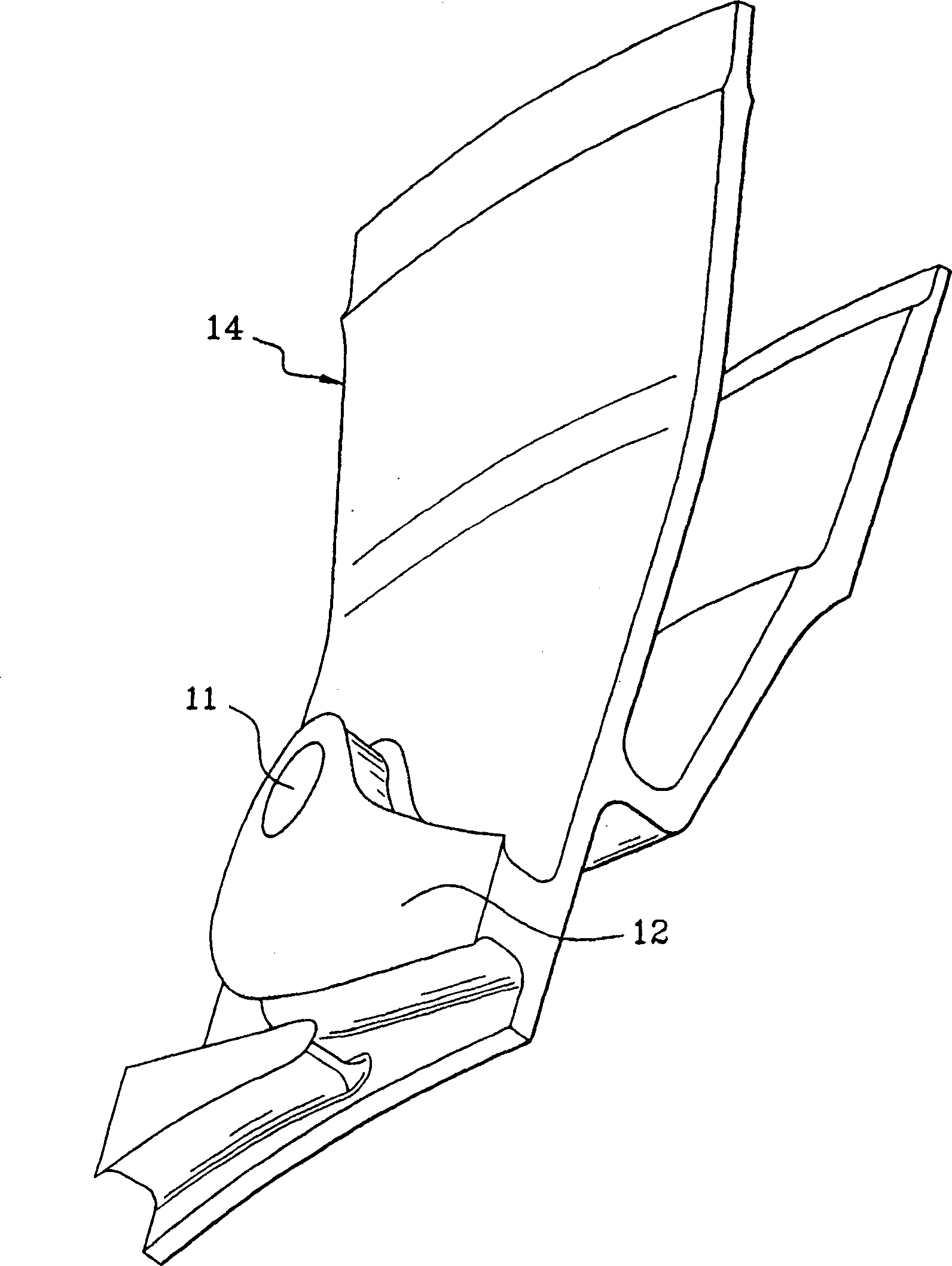

[0024] Referring to FIG. 2 , it can be seen that the turbojet engine notably comprises a stator according to the invention. The stator firstly comprises a pressure chamber 16 delimited by different elements. Note among these elements the outer labyrinth seals 4a, 4b, and the inner labyrinth seals 13a, 13b. The two inner and outer labyrinth seals 13 a , 13 b , 4 a , 4 b are respectively supported by a bracket 14 fixed to the cavity stator 5 and a further bracket 36 fixed to the bracket 14 . The inner labyrinth seal 13a, 13b partially defines a boundary between the pressure chamber 16 and the adjacent first cavity 9, while the outer labyrinth seal 4a, 4b partially defines a boundary between the pressure chamber 16 and the adjacent first cavity 9. The boundary between the adjacent second cavities 10 . The first and second cavities 9 and 10 are separated by a bracket 14 . Note that the stator, downstream of the second cavity 10 in the flow direction of the main duct of the turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com