Plaster hollow large panel pouring concrete wall and manufacturing method thereof

A technology of pouring concrete and manufacturing method, which is applied to the on-site preparation of formwork/formwork/work frame, wall, building components, etc., can solve the requirements of environmental protection, economical rationality, good seismic performance cannot realize the industrialization of residential buildings And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

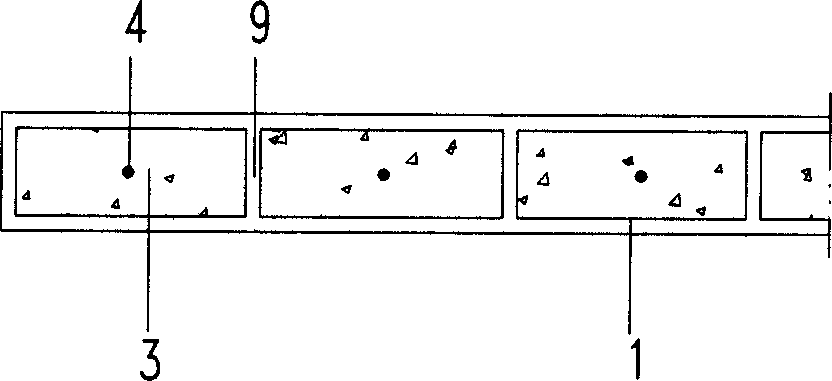

[0055] The porous gypsum hollow board (1) is relatively parallel and vertically arranged on the floor (7), the lower end of the porous gypsum hollow board (1) is connected with the upper end of the floor (7), and the upper end of the porous gypsum hollow board (1) is connected with the upper end of the porous gypsum hollow board (1). The lower ends of the floors (7) are connected.

[0056] The central part of the porous gypsum hollow plate (1) is provided with several plate ribs (9) relatively parallel and equidistant along the porous gypsum hollow plate (1) to form several hollow holes (2), and the hollow holes (2) of the porous gypsum hollow plate (1) ) is relatively parallel and perpendicular to the floor (7).

[0057] The central part of the hollow hole (2) of the porous gypsum hollow plate (1) is provided with several vertical steel bars (4) relatively parallel to the porous gypsum hollow plate (1), and concrete is poured into the hollow hole (2) of the porous gypsum holl...

Embodiment 2

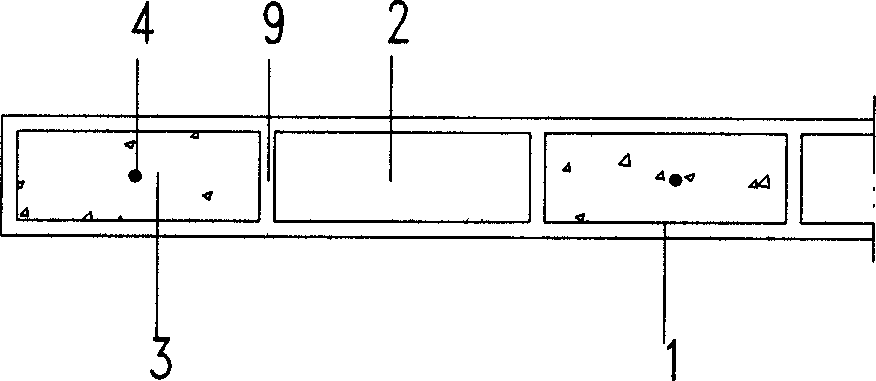

[0059] One end of the porous gypsum hollow plate (1) is connected to the other end of another porous gypsum hollow plate (1) in a relatively vertical L shape, and the porous gypsum hollow plate (1) is connected to the other porous gypsum hollow plate (1). The cross-sectional area of the connected hollow holes (2) forms an L-shape. Inside the L-shaped hollow hole (2), several vertical steel bars (4) are arranged relatively parallel to the porous gypsum hollow plate (1), and the porous gypsum hollow plate (1) is connected to the other In the L-shaped hollow hole (2) at the end connected by a porous gypsum hollow plate (1), several horizontal reinforcing bars (5) are arranged relatively parallel to the porous gypsum hollow plate (1), and the horizontal reinforcing bars (5) and the vertical reinforcing bars (4) are connected with each other, the end L-shaped hollow hole (2) where the porous gypsum hollow plate (1) is connected with another porous gypsum hollow plate (1) is poured...

Embodiment 3

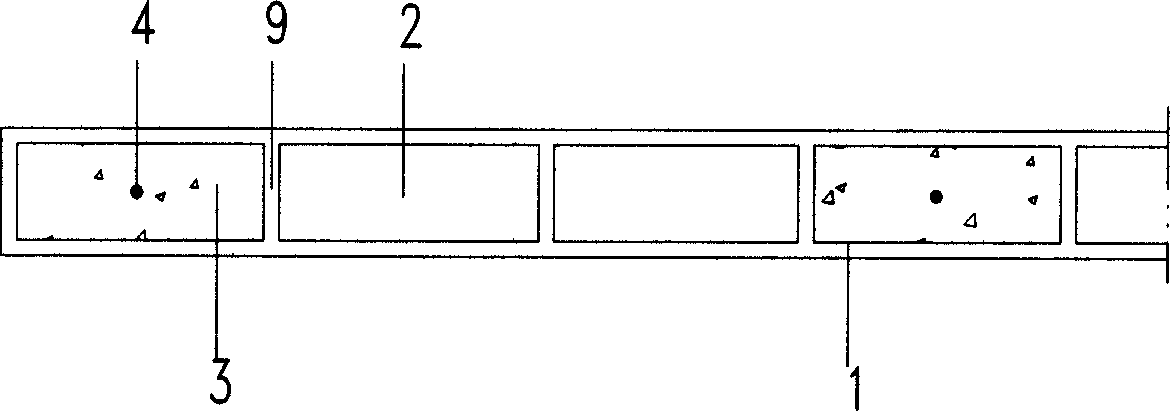

[0063] In the middle part of the hollow holes (2) of the porous gypsum hollow plate (1) separated by at least one hole, several vertical steel bars (4) are arranged relatively parallel to the porous gypsum hollow plate (1), and the hollow holes of the porous gypsum hollow plate (1) (2) The inner pouring concrete constitutes the pouring core column (3), and the lower end and the upper end of the pouring core column (3) are respectively connected with the upper part of the floor (7) ring beam (8) and the upper part of the floor (7) ring beam (8). The lower part is connected.

[0064]In the hollow hole (2) adjacent to each end of the L-shaped hollow hole (2), several vertical steel bars (4) are arranged relatively parallel to the porous gypsum hollow plate (1), and each end of the L-shaped hollow hole (2) In the adjacent hollow holes (2), a number of horizontal steel bars (5) are arranged relatively parallel to the porous gypsum hollow plate (1), one end of the horizontal steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com