Hot-piping planar solar heater collector

A solar heat collector, a flat-plate technology, applied to solar heat collectors, solar heat collectors using working fluids, solar thermal energy, etc., can solve the problems of easy freezing and cracking of the upper circulation header heat collection tube, heat collection tube structure blockage, Issues that affect the thermal efficiency of the collector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

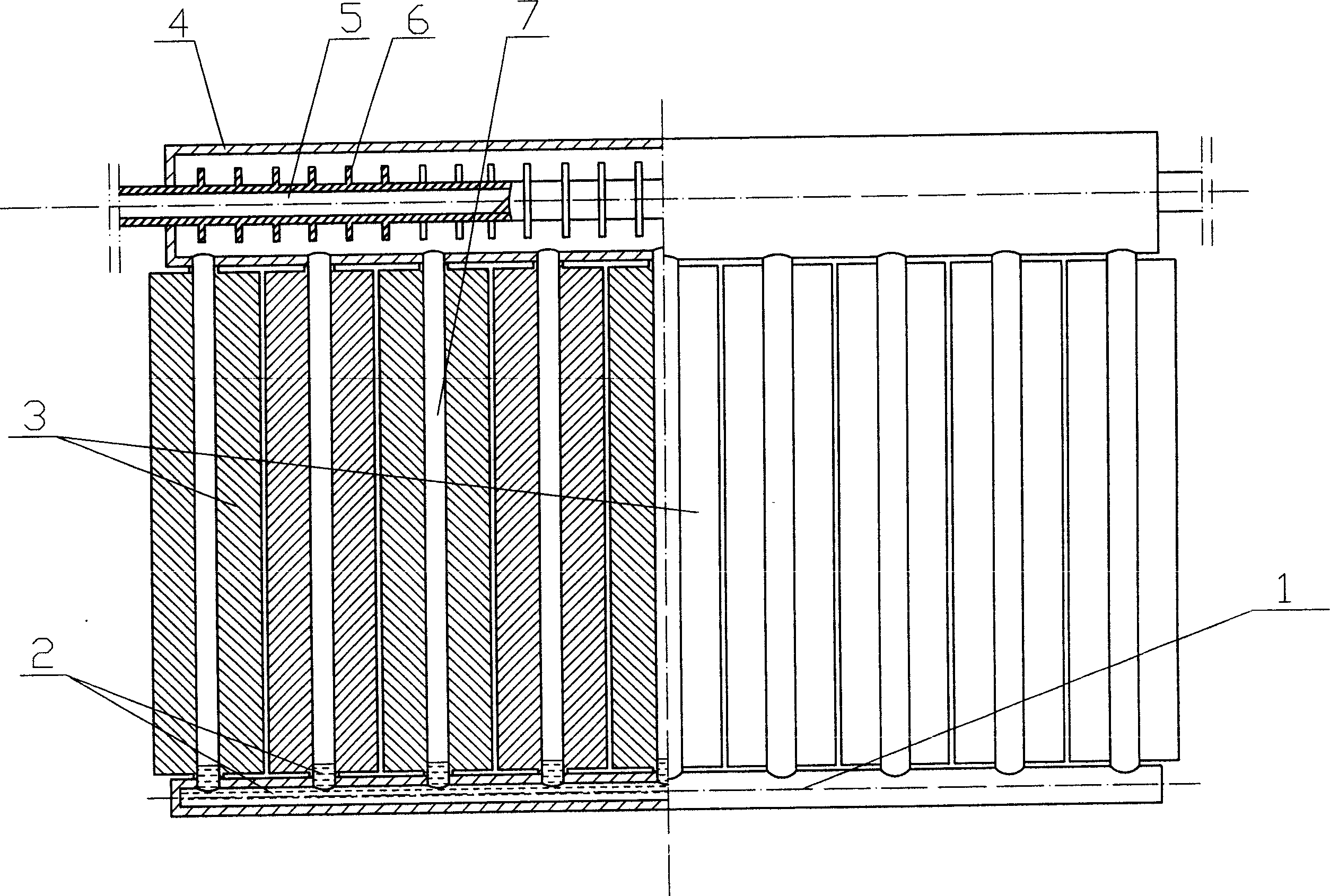

[0015] Such as figure 1 with 2 , The heat pipe flat-plate solar collector is mainly composed of the upper circulation header 4, the lower circulation header 1, the heat collection tube 7 and the heat collection fin 3, etc. There are several between the upper circulation header 4 and the lower circulation header 1. The heat collection tube 7 is connected, the heat collection fins 3 are arranged on both sides of the heat collection tube 7, a heat exchange tube 5 is arranged in the upper circulation header 4, and the head and tail ends of the heat exchange tube 5 extend from the upper circulation header 4 outside; the space enclosed by the upper circulation header 4, the lower circulation header 1 and the heat collection tube 7 contains a heat pipe medium liquid 2, and the heat exchange tube 5 is provided with a number of fins 6 along the radial direction of the heat exchange tube 5 The heat pipe medium liquid 2 occupies 3% of the enclosed space volume of the upper circulation heade...

Embodiment 2

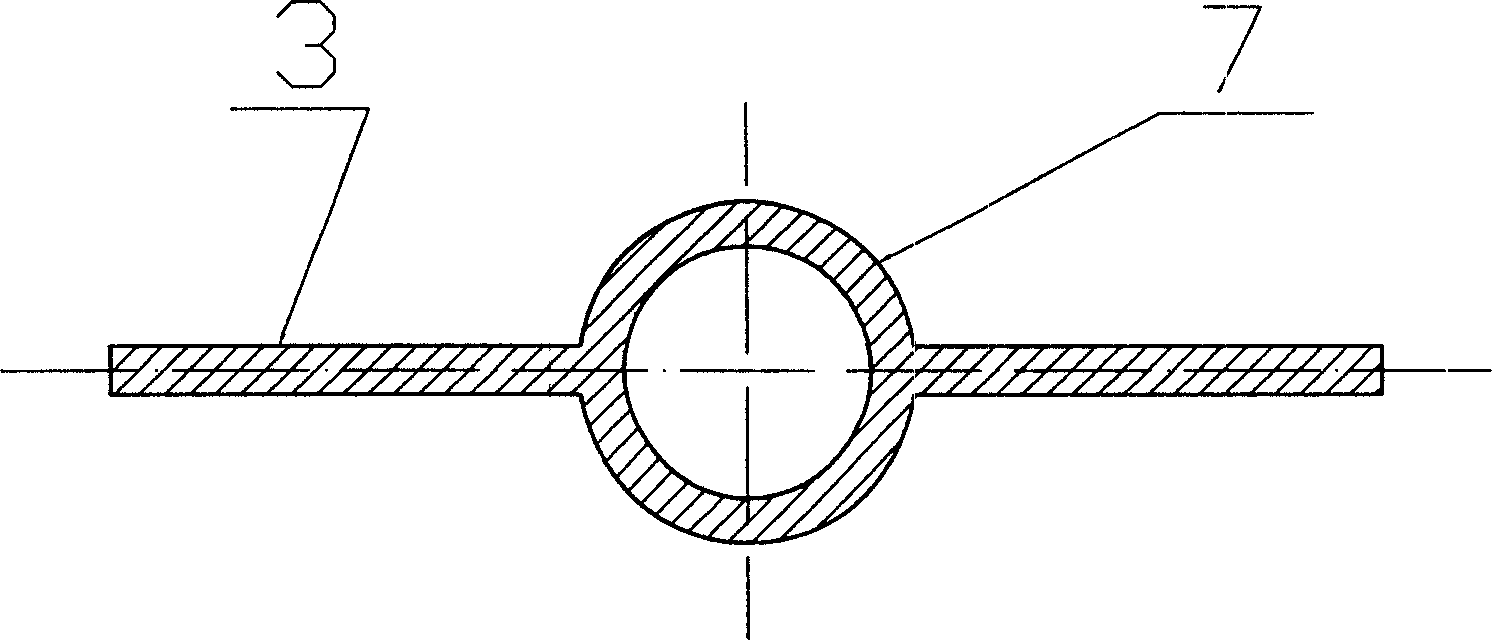

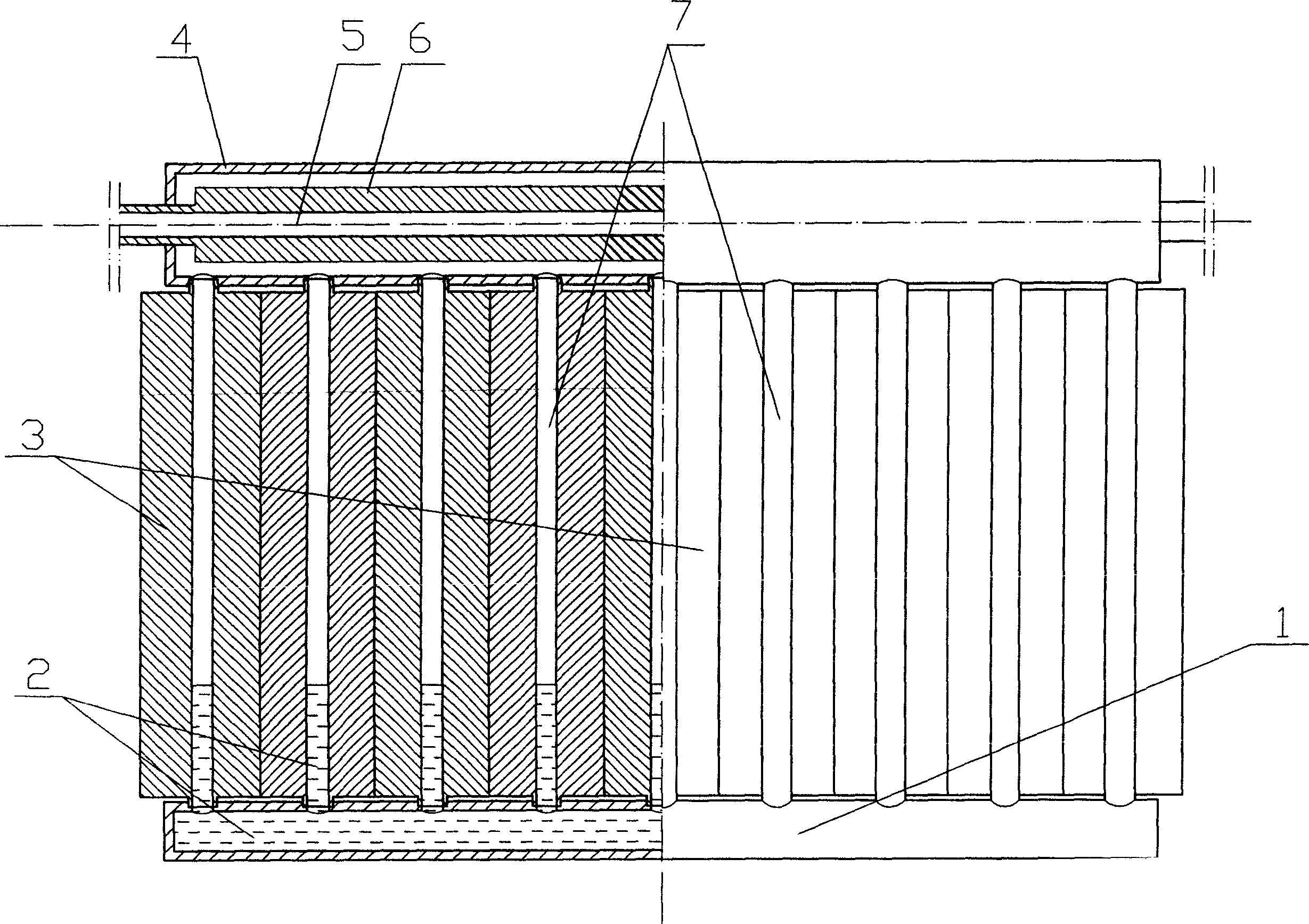

[0017] Such as image 3 , 4 And 5, the heat pipe flat plate solar collector is mainly composed of the upper circulation header 4, the lower circulation header 1, the heat collection tube 7 and the heat collection fin 3, etc. The upper circulation header 4 and the lower circulation header 1 are separated by Several heat collection tubes 7 are connected, heat collection fins 3 are arranged on both sides of the heat collection tube 7, the heat collection fins 3 and the heat collection fins on the adjacent heat collection tubes overlap each other, and the upper circulation header 4 is provided with a heat exchanger The heat pipe 5, the head end and the tail end of the heat exchange tube 5 protrude outside the upper circulation header 4; the space enclosed by the upper circulation header 4, the lower circulation header 1 and the heat collection tube 7 contains the heat pipe medium liquid 2, The heat exchange tube 5 is provided with a plurality of fins 6 along the axial direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com