Method and apparatus for clearing rotary kiln ring

A rotary kiln and kiln ring technology, applied in descaling devices, furnaces, mechanical equipment, etc., can solve the problems of kiln skin peeling, calcination deterioration, kiln lining cracking, etc., and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

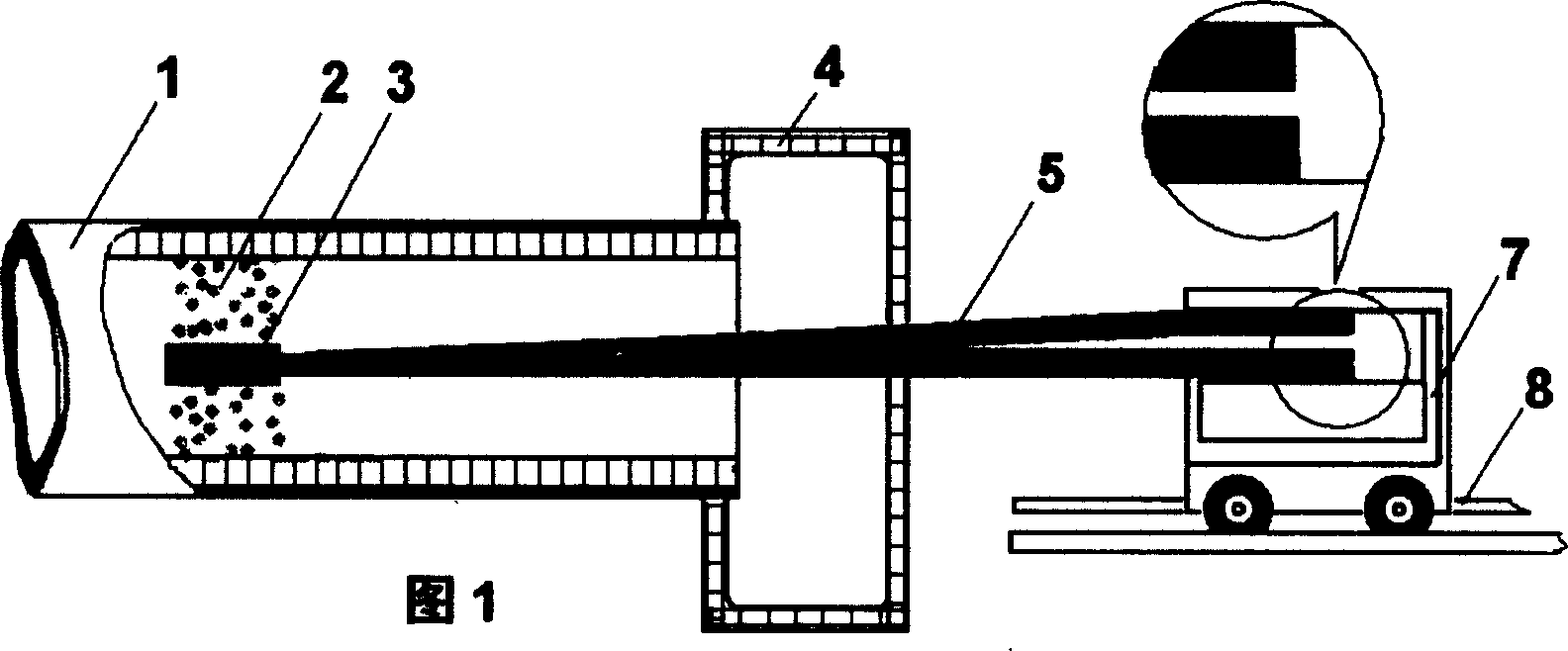

[0011] In the embodiment shown in Figure 1, a group of rails (8) are set near the kiln tail (4) of the rotary kiln, and a trolley (7) is arranged on the rail (8), and a stretchable Entering the cleaning arm (5) of the kiln ring forming area (2) of the rotary kiln, the front end of the cleaning arm (5) is provided with a scraper (3). Open an opening at the kiln tail (4) of the rotary kiln, extend the cleaning arm (5) and the scraper (3) into the kiln circle forming area (2) in the rotary kiln, and use the Kinetic energy and relative displacement, to automatically clear kiln circles or prevent kiln circles from forming.

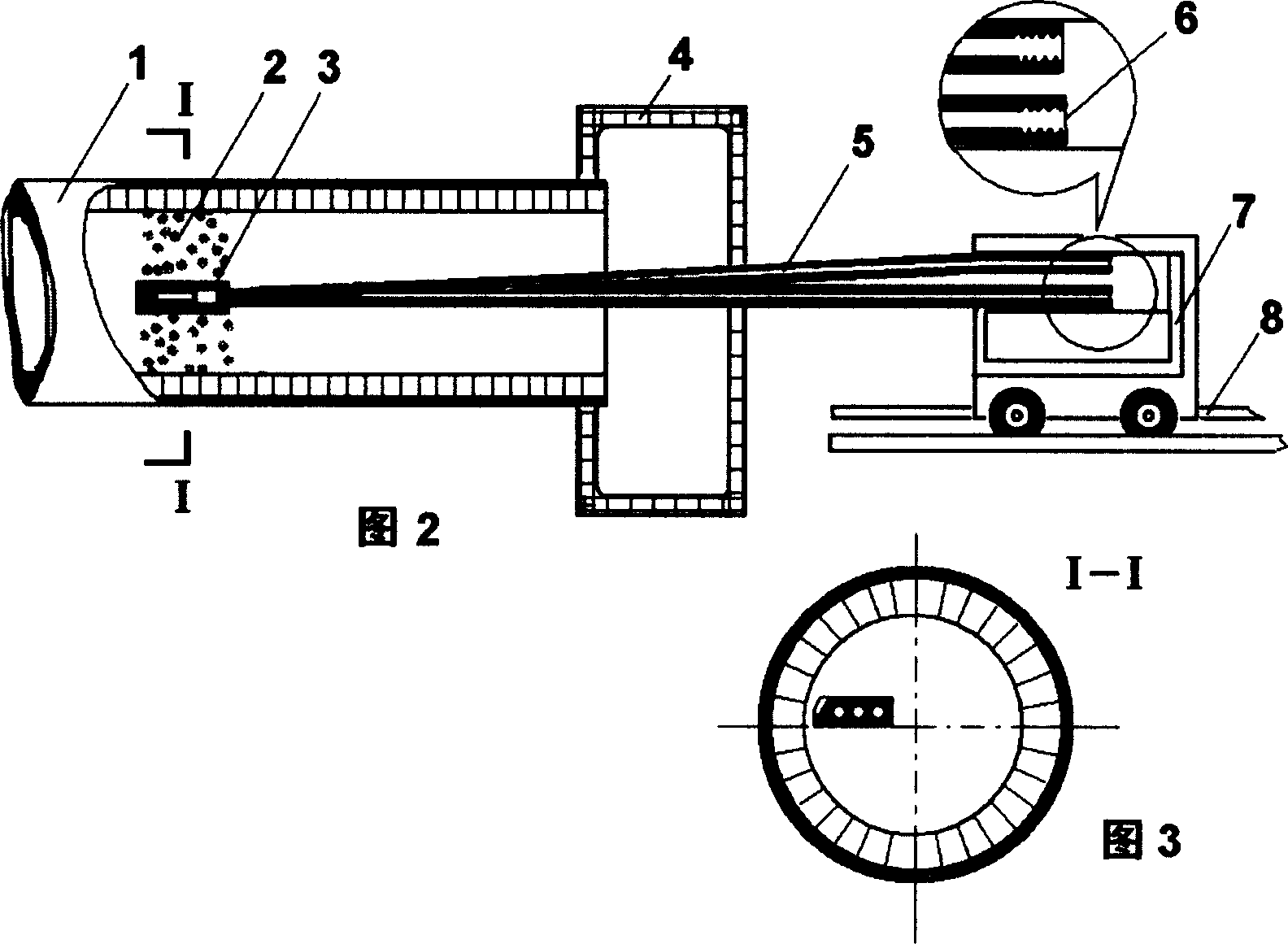

[0012] In another embodiment shown in Fig. 2, near the kiln tail (4) of the rotary kiln, a group of tracks (8) are set, and a trolley (7) is provided on the track (8), and a trolley (7) is provided with a The cleaning arm (5) that can extend into the kiln ring forming area (2) of the rotary kiln, the front end of the cleaning arm (5) is provided with a scraper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com