Linear compressor

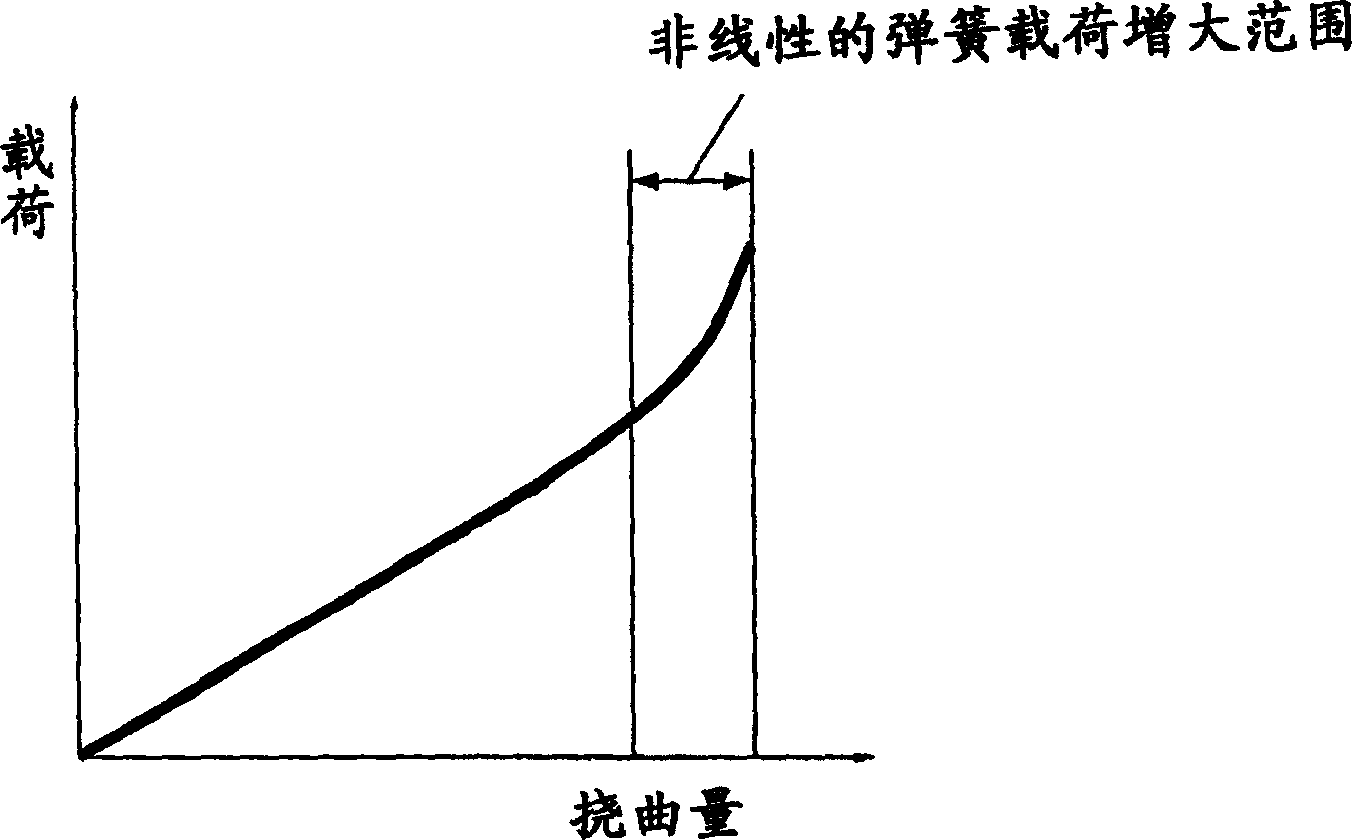

A technology of linear compressors and compression mechanisms, applied in mechanical equipment, machines/engines, liquid variable displacement machines, etc., which can solve problems such as collision noise, sudden changes in piston amplitude, and damage to pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

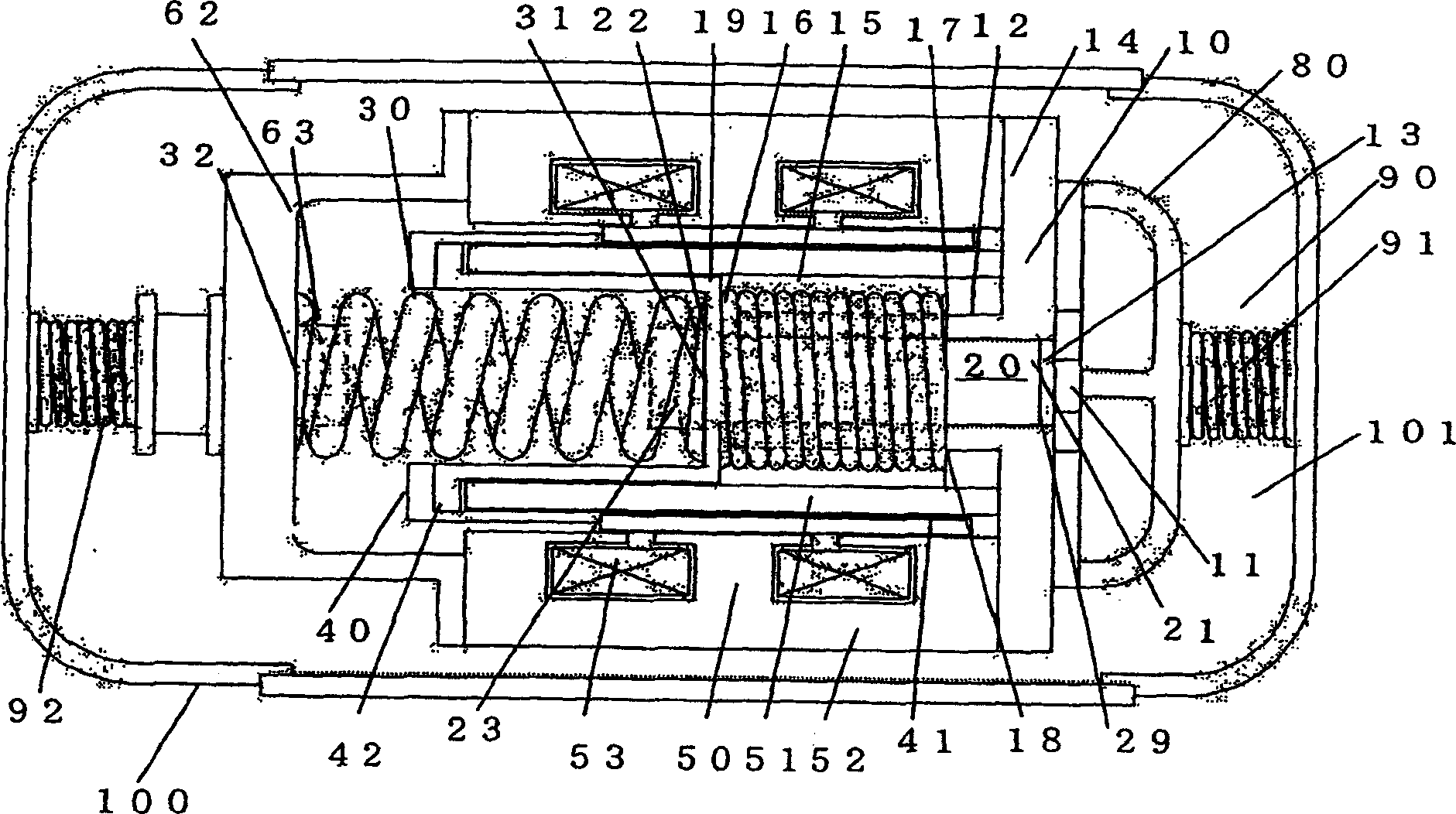

[0021] Next, an embodiment of the linear compressor of the present invention will be described with reference to the drawings. first according to figure 1 The overall structure of the linear compressor of the present invention will be described.

[0022] Generally, the linear compressor consists of a cylinder body 10, a piston 20, a movable part 40 and a fixed part 50 constituting a linear motor part, a spring mechanism part formed by a coil spring, an end cover part 80, a support mechanism part 90, an airtight container 100 poses.

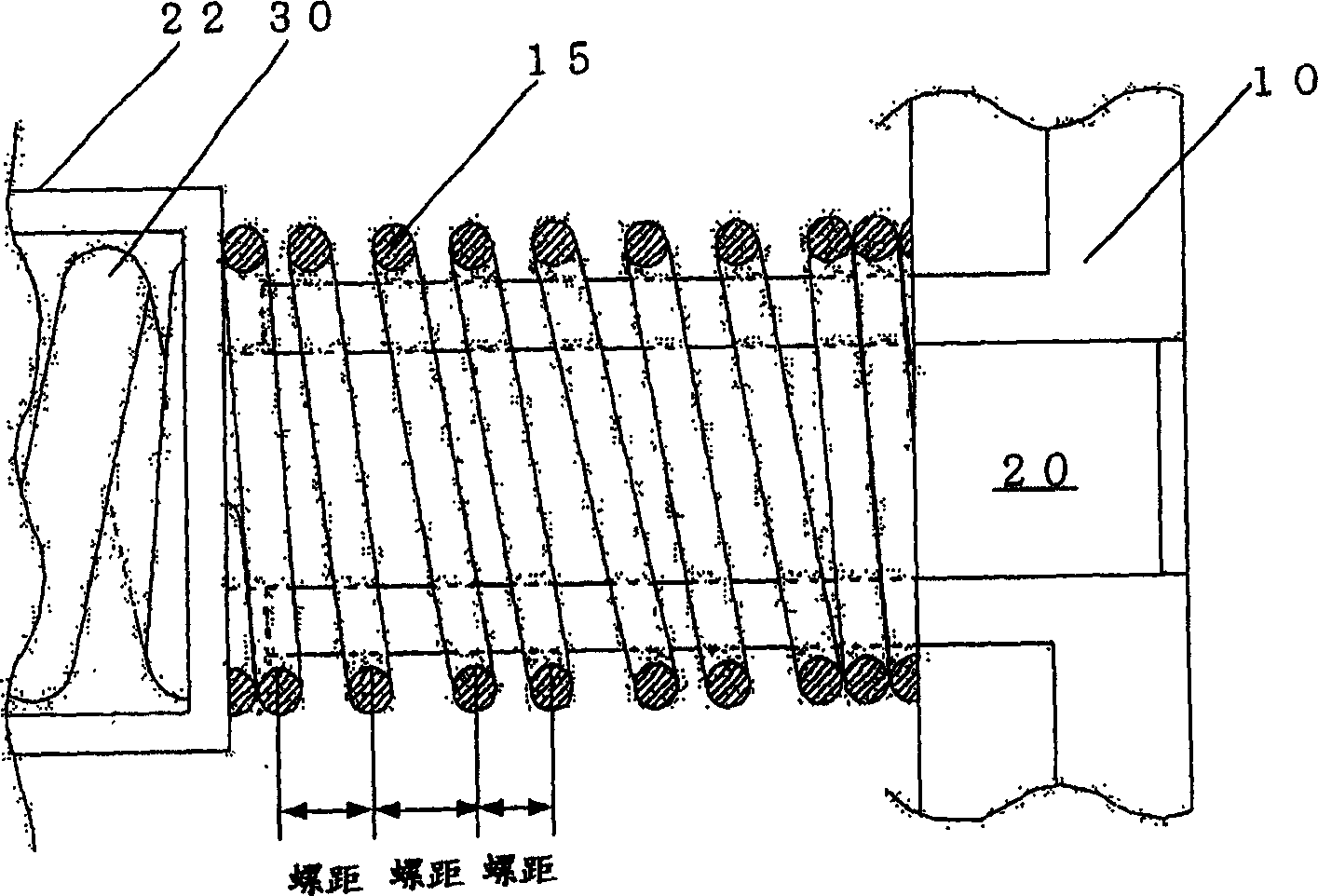

[0023] The cylinder 10 is composed of a cylinder end surface 11 on which a valve body (not shown) is attached, a flange portion 14, and a protrusion 12 protruding from the flange portion 14 in one direction (left direction in the figure). The piston 20 has a frame body 22 processed with recesses for accommodating the post portion 21 and the coil spring 30 . A protrusion 23 is provided on the inner bottom surface of the concave portion of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com