Two translation-rotary parallel connection mechanism for imaginary axis digital control machine tool and robot

A technology of CNC machine tools and robots, which is applied in the direction of program control manipulators, manipulators, metal processing machinery parts, etc., and can solve problems such as unfavorable control, small working space, and difficult kinematics solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

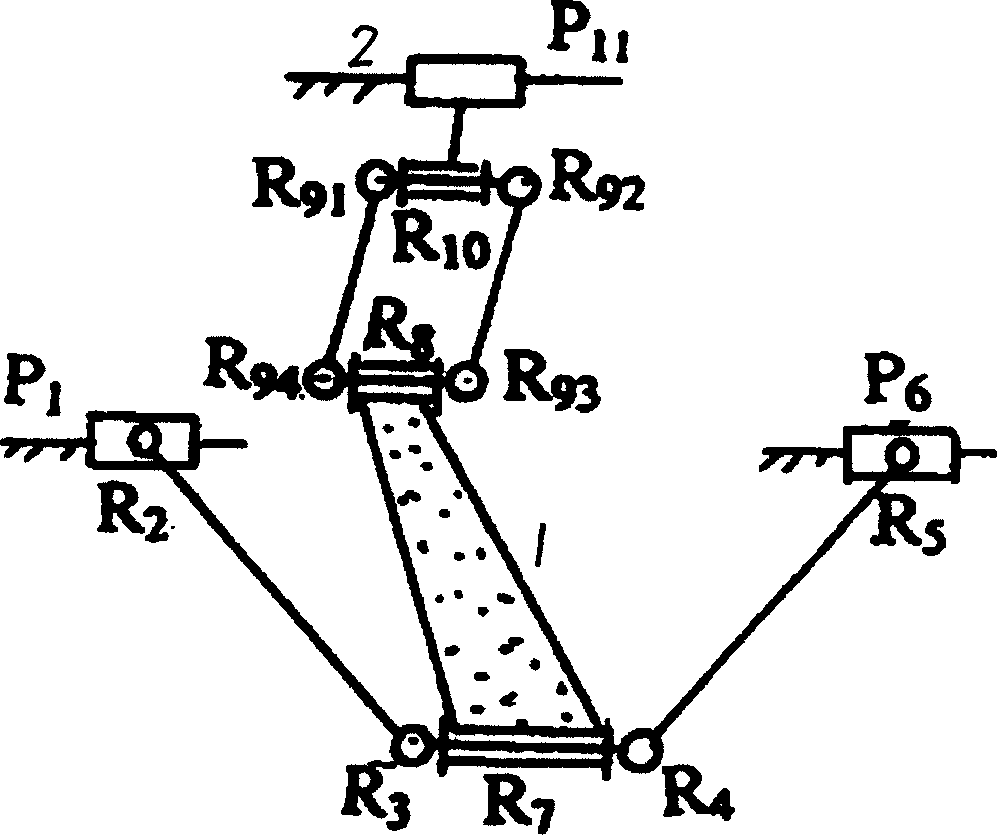

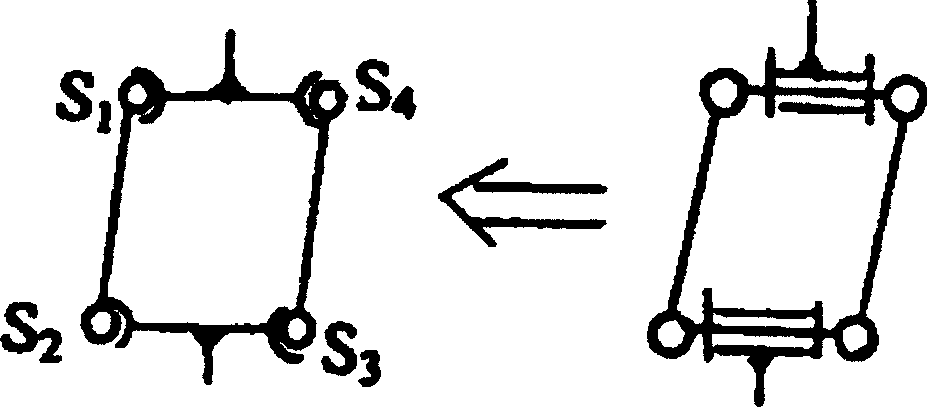

[0008] attached figure 1 The structure shown may also be an embodiment of the invention. It consists of a dynamic platform 1, a static platform 2 and two generalized branches with different structures. The first generalized branch is routed by the mobile pair P 11 , 4 revolving pairs R perpendicular to the moving pair 91 , R 92 , R 93 , R 94 The parallelogram circuit formed, and the two revolving pairs R whose axes respectively coincide with the opposite sides of the quadrilateral 10 , R 8 formed in series. The second generalized branch consists of 4 revolving pairs R 2 , R 3 , R 4 , R 5 and 2 mobile vice P 1 ,P 6 The 6-bar planar circuit and a mutually perpendicular revolving pair R 7 formed in series. The end components of the two generalized branches are fixedly connected to the dynamic and static platforms respectively, and the two revolving pairs R located on the dynamic platform 7 , R 8 Arranged in parallel with each other, there are 3 moving pairs P loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com