Top fire room combstion system for gasoline engine piston

A combustion system and ignition chamber technology, which is applied in the field of direct injection gasoline engine piston apex fire chamber combustion system, can solve the problems of narrow gas mixture concentration range and inability to use higher compression ratio in gasoline engines, and improve exhaust pollution and fuel consumption The effect of rate reduction and economic improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

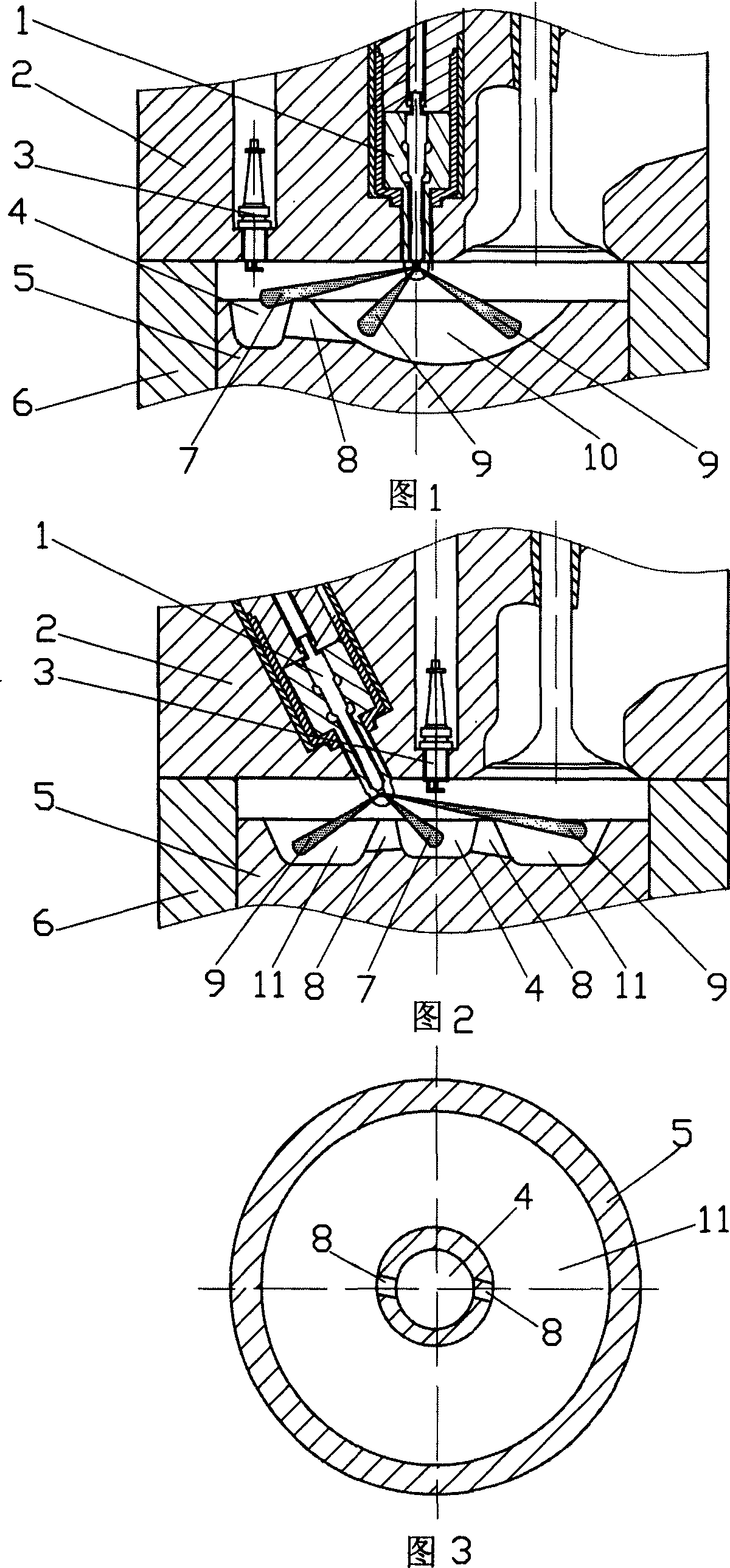

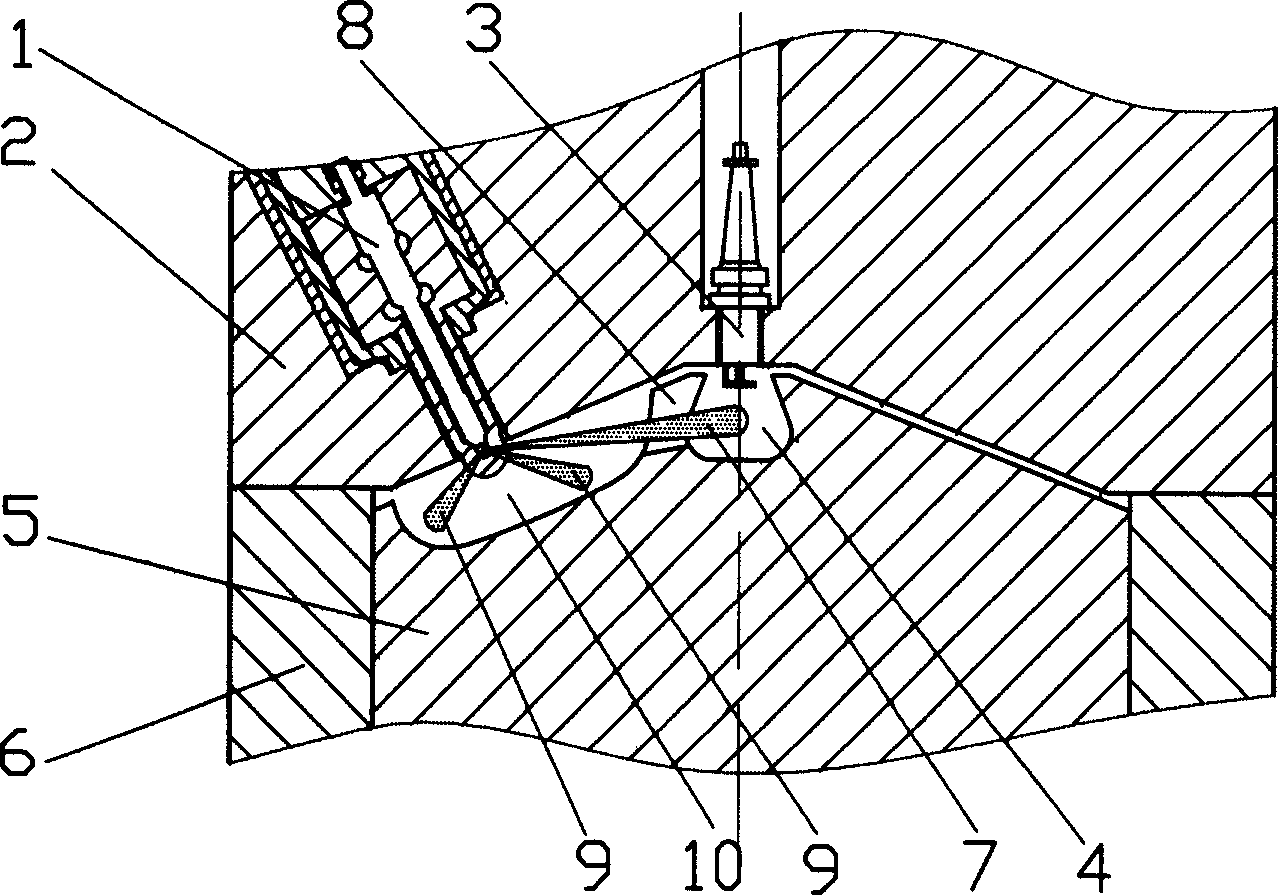

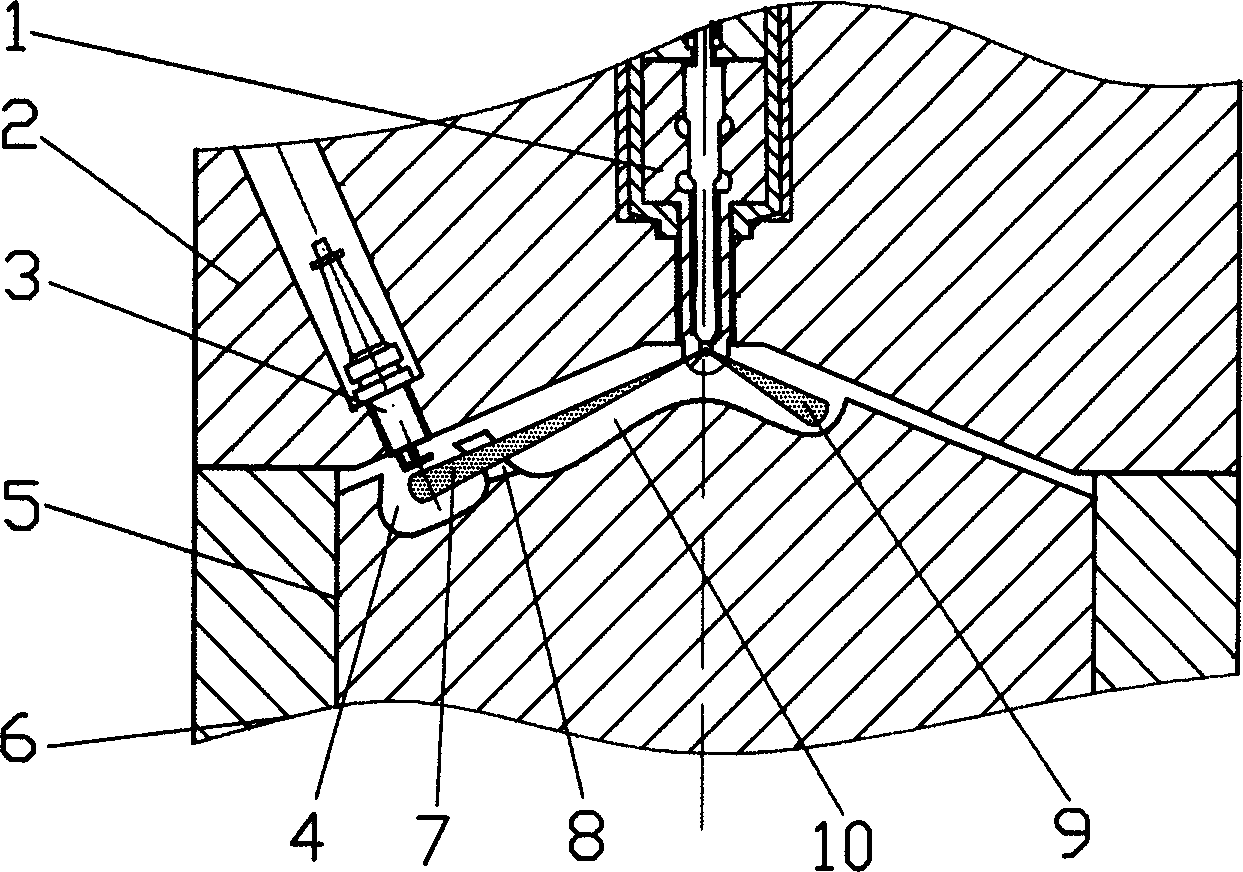

[0014] In the embodiment shown in Fig. 1, a main combustion chamber is formed by the cylinder head 2, the piston 5 and the cylinder liner 6, and a small combustion chamber 4 and a large combustion chamber 10 are arranged on the top of the piston 5, and the small combustion chamber 4 There is a passage 8 connected with the large combustion chamber 10, and according to the requirements of tissue combustion, the passage 8 can be arranged at any angle between the normal direction and the tangential direction with the periphery of the combustion chamber. When the piston 5 is near the top dead center, the cylinder head 2 and the small combustion chamber 4 form an ignition chamber, and the cylinder head 2 and the large combustion chamber 10 form a main combustion chamber. A bundle of auxiliary oil jets 7 ejected from the gasoline nozzle 1 installed on the cylinder head 2 is directly injected into the ignition chamber, at least two main oil jets 9 are injected into the main combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com