Conical surface hard seal ball valve

A hard seal and conical surface technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as complex structure, poor sealing performance stability, and difficult manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

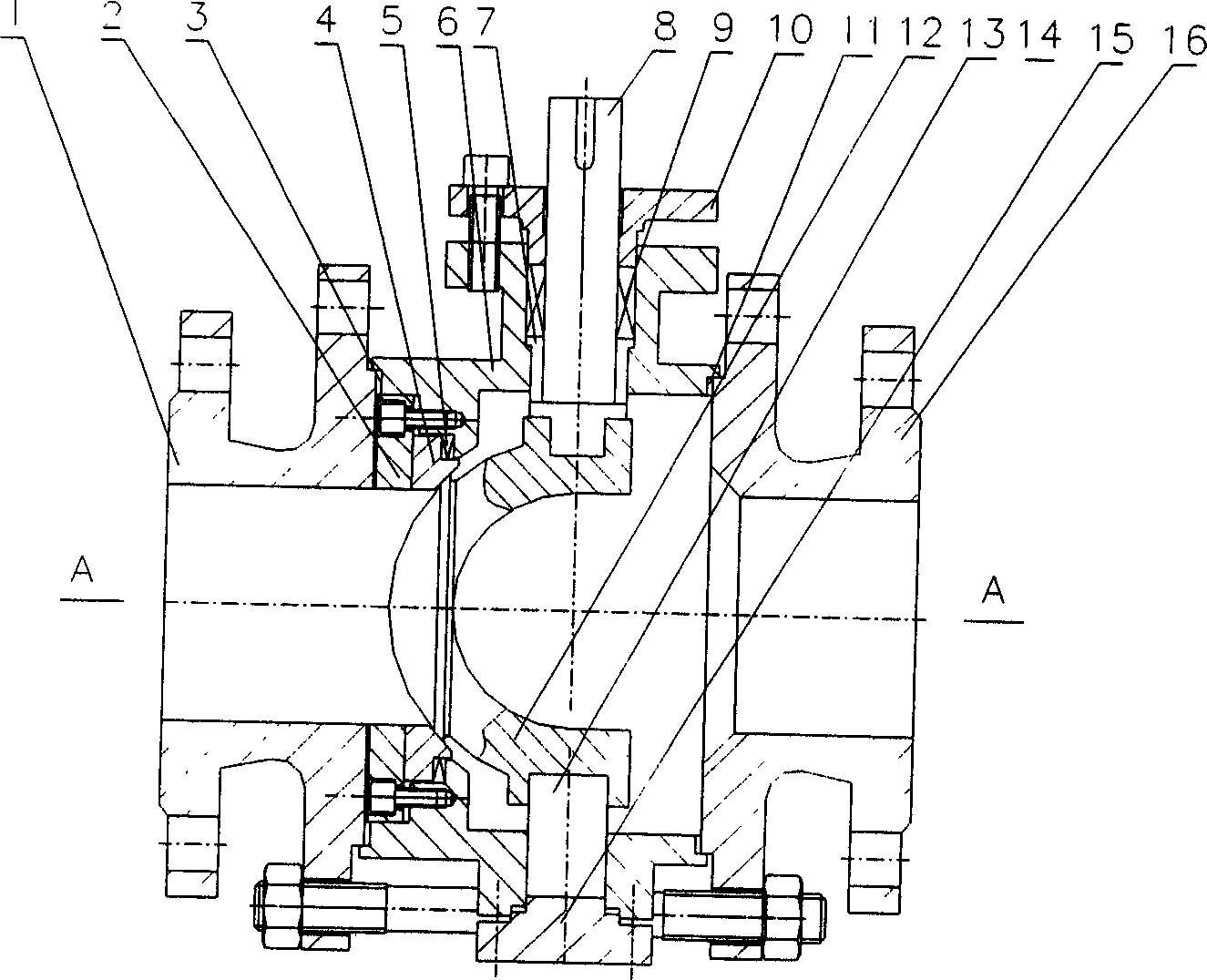

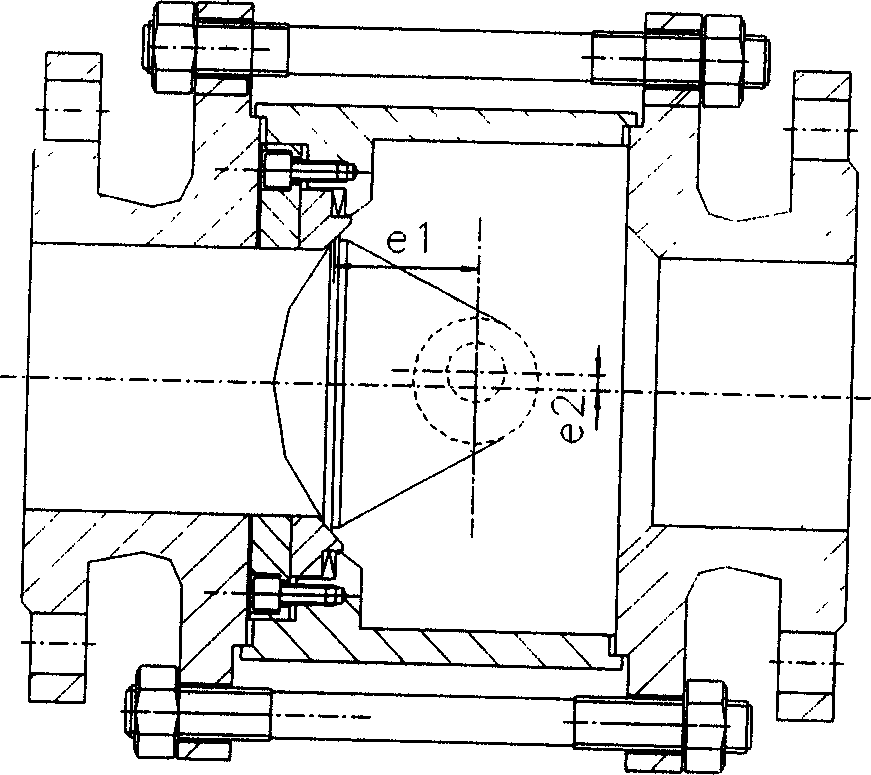

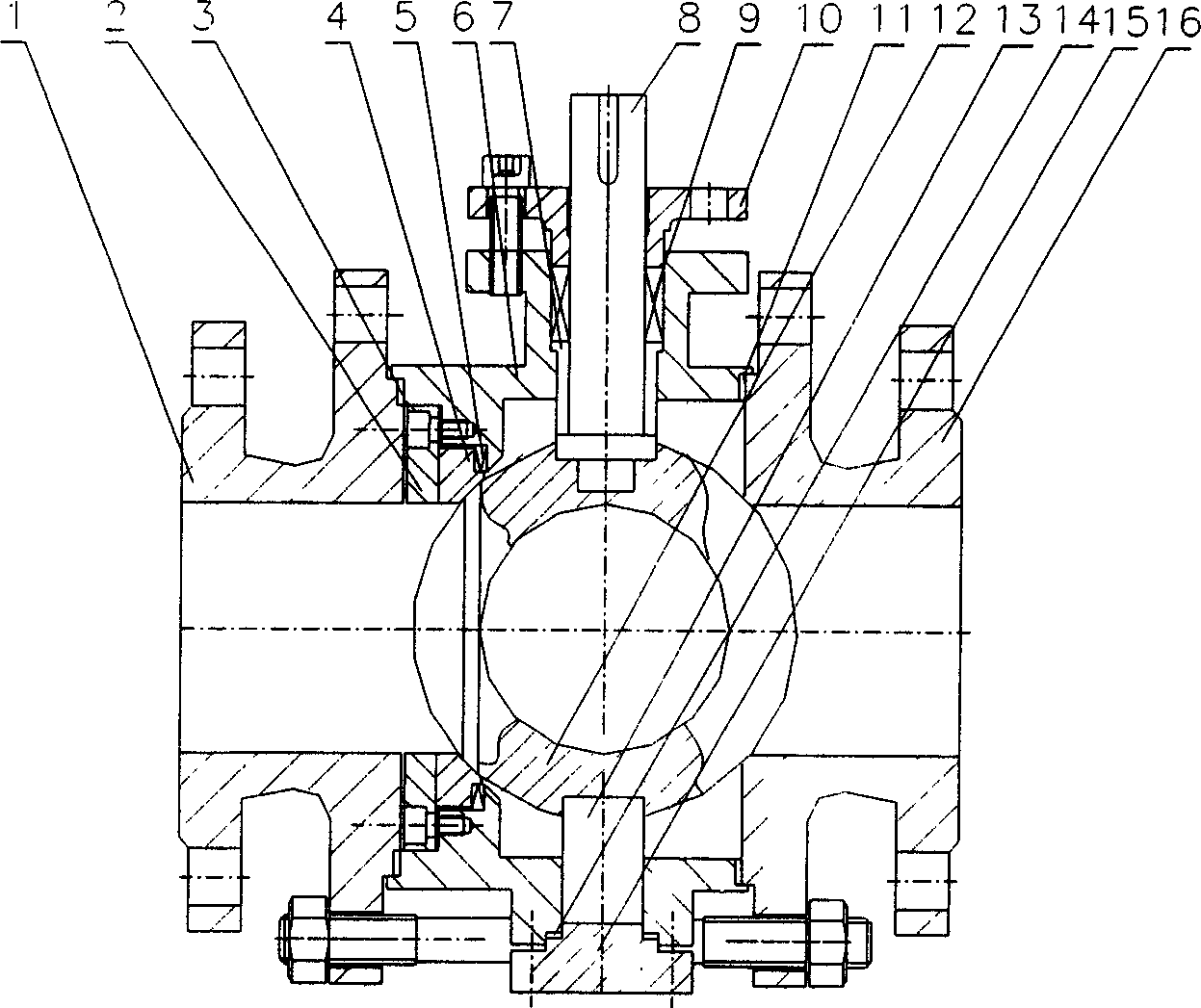

[0009] The tapered surface hard-sealed ball valve includes a valve body 6, a ball core 12 is arranged in the valve body, and the ball core is respectively connected with the upper valve stem 8 and the lower valve stem 13, and an elastic washer 5 and a pressure plate are arranged between the valve seat 4 and the valve body 6. 2. The sealing surface of the ball core 12 and the sealing surface of the matching valve seat 4 are all conical surface structures. The upper valve stem 8 and the lower valve stem 13 form the rotation axis of the ball core 12, and the rotation axis of the ball core 12 is relative to the ball. The sealing surface of the core 12 has an eccentricity along the axial direction of the sealing surface of the ball core 12 and a radial direction perpendicular to the rotation axis of the ball core 12 .

[0010] Said core is hemispherical or whole spherical. The elastic washer 5 is O-shaped, C-shaped, U-shaped, V-shaped metal elastic washer, metal wound washer or non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com