Method for detecting emergy wheel surface topography using laser scan triangular method

A laser scanning, grinding wheel surface technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of longer measurement time and low measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the detection system shown in the accompanying drawings, the specific implementation method of the present invention is described as follows:

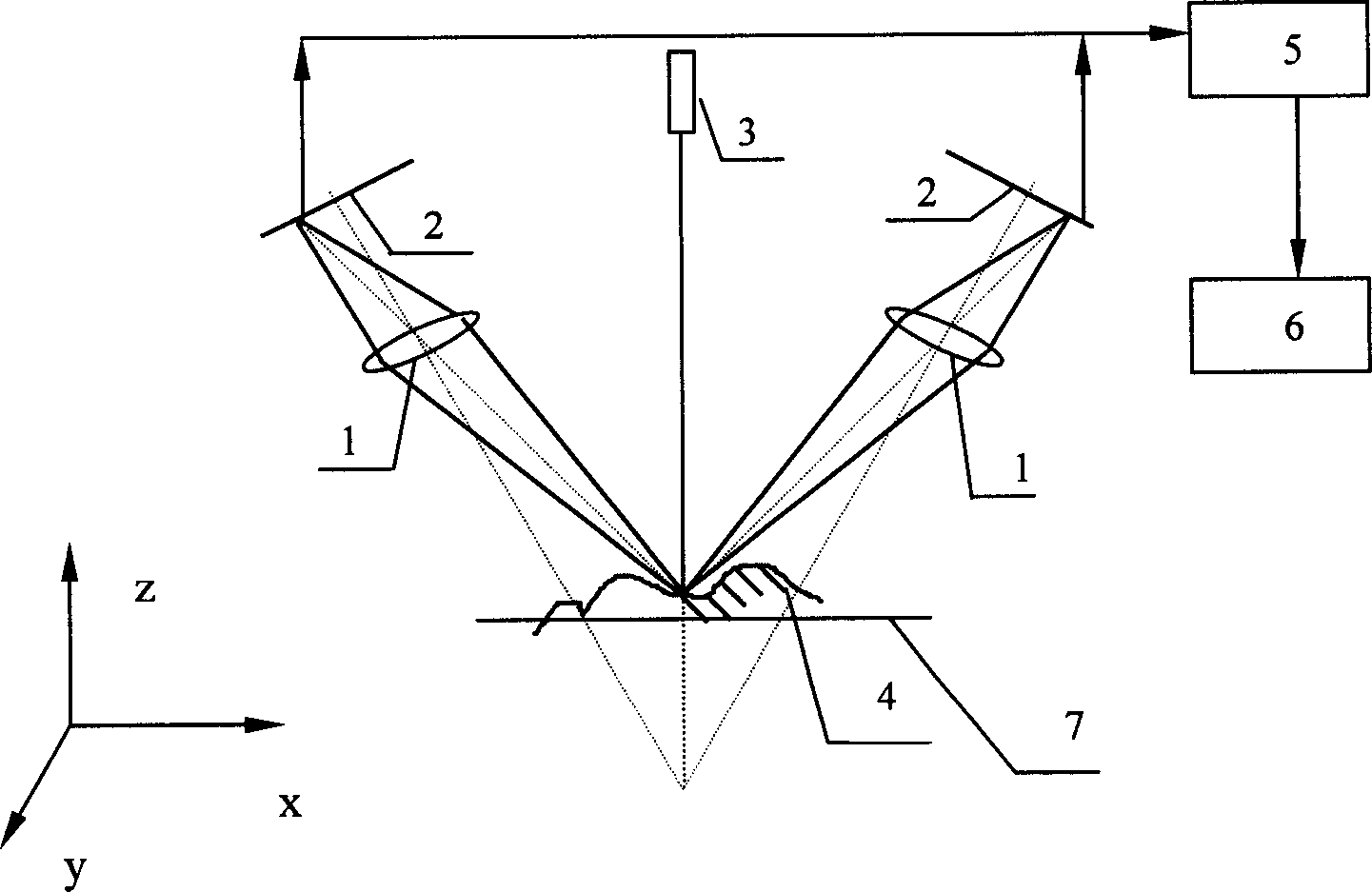

[0018] A laser scanning triangulation detection system consisting of a Replica500 laser scanning system, an analog-to-digital conversion module 5 and a computer 6 is adopted, wherein the Replica500 laser scanning system is composed of a Replica500 laser scanning head and a scanning table 7, and the Replica500 laser scanning head consists of two lens groups 1 , two position sensors 2, and a neon laser 3; select the 46# particle size resin bond SiC grinding wheel 4 (250×70×25) with organization number 5 as the tested grinding wheel;

[0019] In the first step, before the measurement, the SiC grinding wheel 4 is firstly dressed with a single-point diamond pen;

[0020] In the second step, place the trimmed resin-bonded SiC grinding wheel 4 on the scanning table 7 directly under the Laser scanning head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com