Cable and its in-site construction method

A technology for cables and insulating outer layers, applied in the field of cables, can solve the problems of affecting the fixing effect, troublesome construction and wiring, and cumbersome on-site construction, and achieve the effect of good fixing effect, simple structure and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a cable, which is composed of an insulating outer layer and a wire arranged inside, wherein one side of the insulating outer layer is a plane.

[0028] The middle part of the plane of the insulating outer layer is provided with a groove.

[0029] The field construction method of described cable, comprises the steps:

[0030] coating the insulating outer plane portion of said cable with an adhesive;

[0031] Bond the adhesive-coated side of the cable to the roof.

Embodiment 2

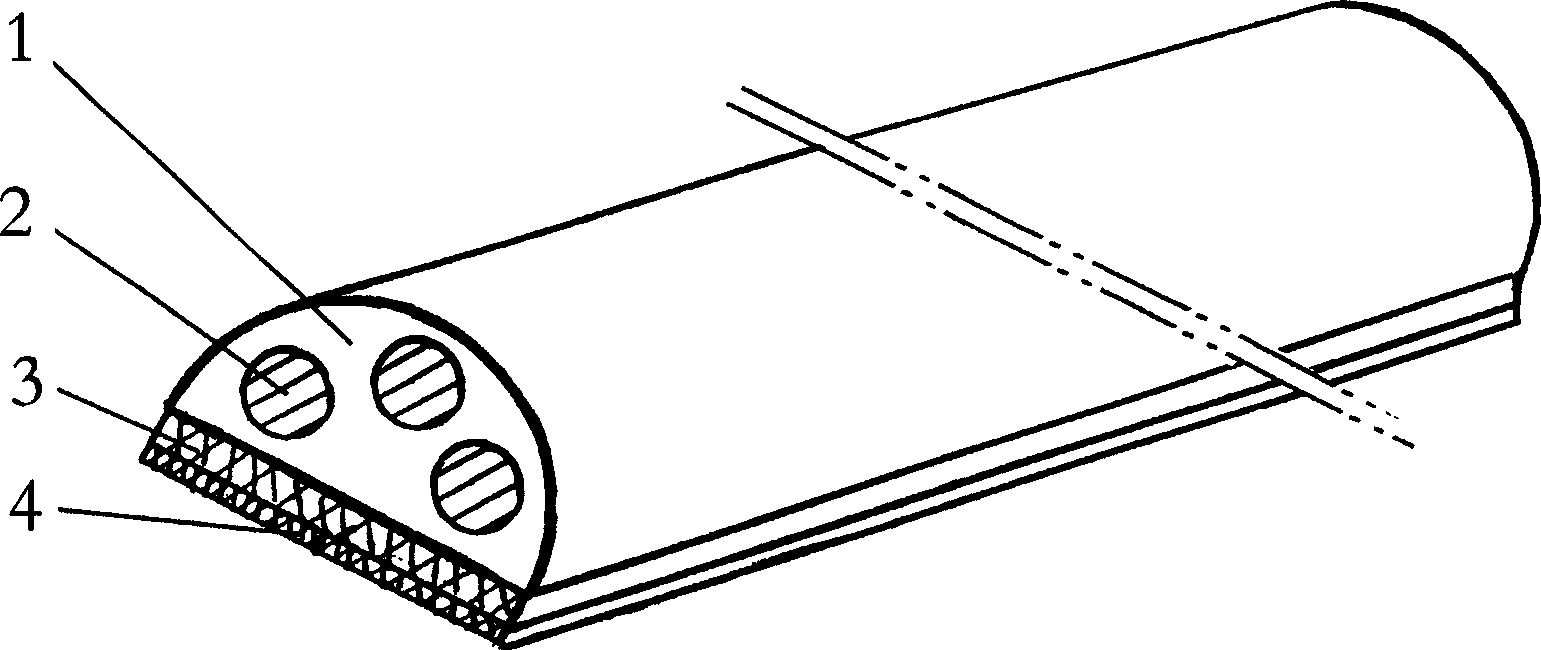

[0033] figure 1 It is a schematic diagram of the structure of the present invention, and the structure of the present invention is as follows: three wires 2 are arranged in the insulating outer layer 1, one side of the insulating outer layer 1 is a plane, and the bonding layer 3 is connected to the plane, and the plane connected to the bonding layer can be It can be a smooth plane or a rough plane. The shape of the section of the insulating outer layer is a semicircle. The other side of the adhesive layer 3 connected to the plane of the insulating outer layer 1 is also provided with a protective layer 4 for protecting the adhesive layer 3 . Wherein the bonding layer 3 can be common adhesive or viscose paper, as long as it can be firmly connected with the roof. Protective layer 4 can be the paper that one side is glossy.

[0034] The bonding layer 3 can be set intermittently or continuously according to the needs of on-site construction.

[0035] The middle part of the plan...

Embodiment 3

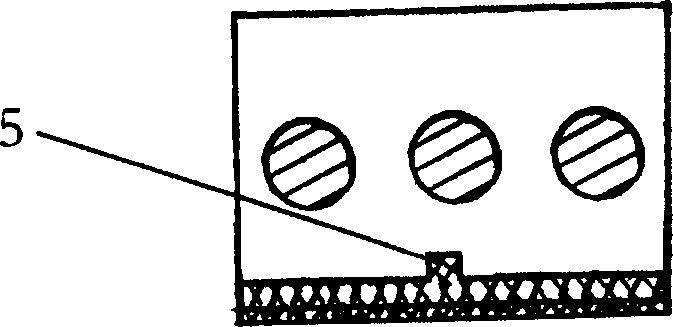

[0037] figure 2 It is the structural diagram of the second embodiment of the present invention, the cross-section of the insulating outer layer described in the first embodiment is rectangular, and the other is the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com