Motor with turbine and worm decelerator

A reduction mechanism, worm gear technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem of affecting the output torque and life of the worm gear reduction mechanism, affecting the rotational rigidity and stability of the motor, armature pieces and commutators. Increase the diameter and other problems to achieve the effects of reducing vibration and noise, improving output torque, and improving rigidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

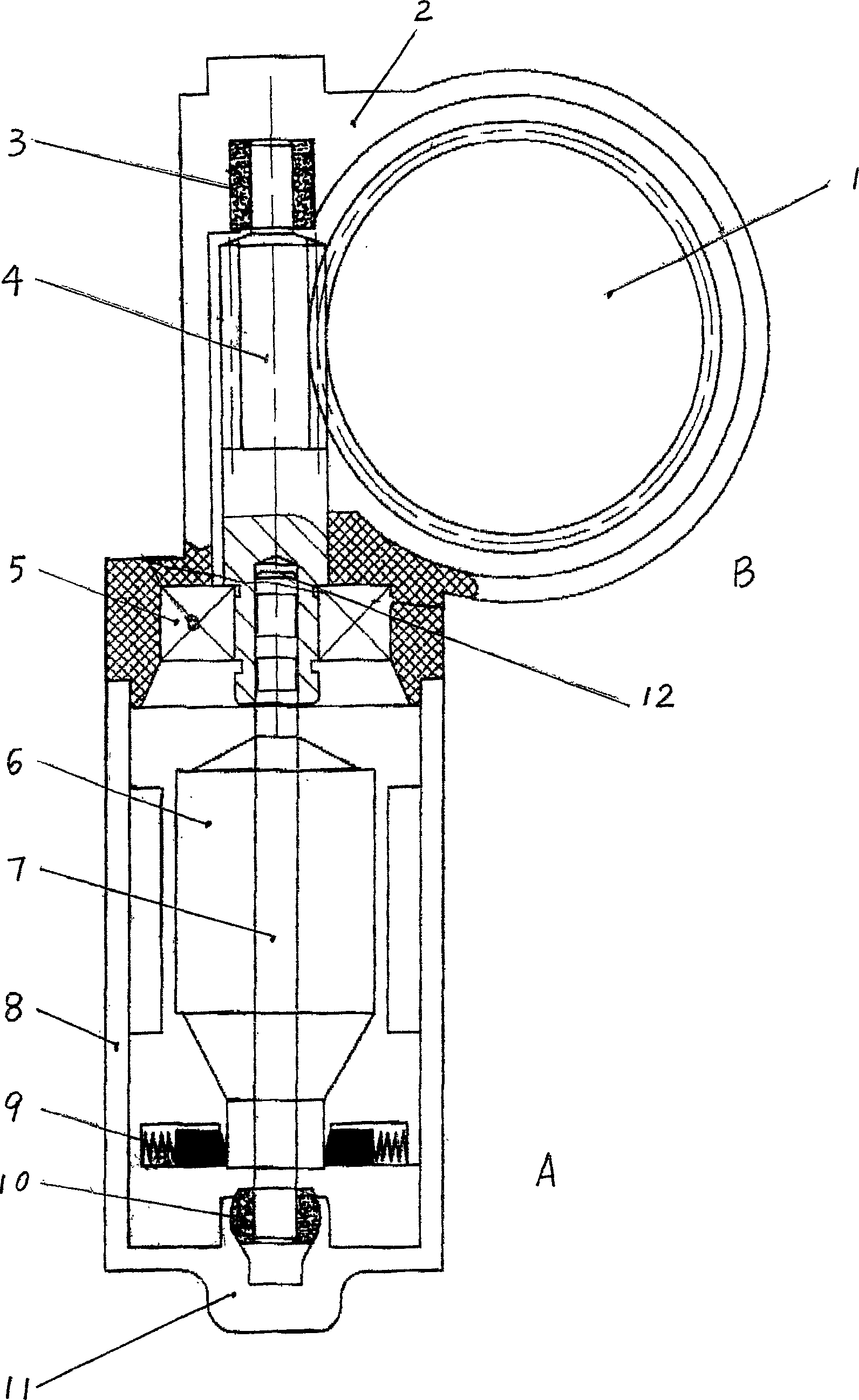

[0010] This example is a miniature motor, and the worm gear reduction device B installed in the reduction mechanism housing 2 is connected with the motor A transmission installed in the motor housing 8 .

[0011] The armature assembly 6 in the motor A is installed on the armature shaft 7, the worm 4 in the worm gear reduction mechanism B is connected to the worm gear 1, the worm 4 and the armature shaft 7 are split structures, and the armature One end of the shaft is inserted into the processing hole on the end face of the worm, and is coaxially connected with the worm through an adhesive. The armature shaft 7 has a groove 12 on the side wall of its connection with the worm. The function of this groove is to ensure There is sufficient strength when the armature shaft is bonded to the worm.

[0012] The end of the armature shaft 7 away from the worm is connected to the rear end cover 11 of the motor casing through a bearing 10, the bearing 10 is a ball bearing, the ball bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com