Organic luminous display element and its producing method

A technology of light-emitting display and organic light-emitting layer, which is applied in electrical components, light-emitting materials, electroluminescent light sources, etc., and can solve the problems of rising driving voltage of components, reducing efficiency, and affecting the life of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

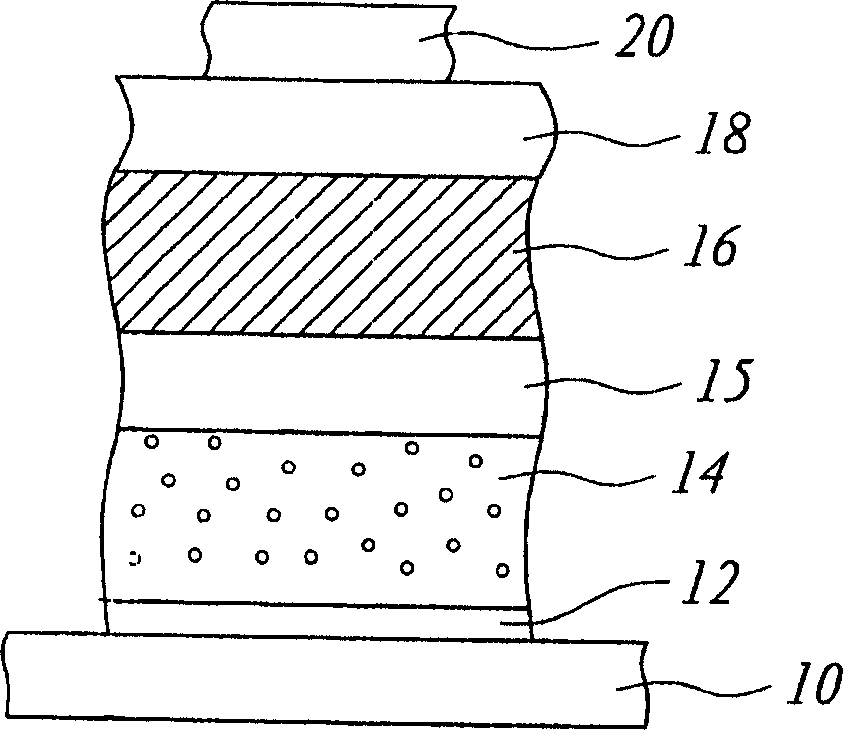

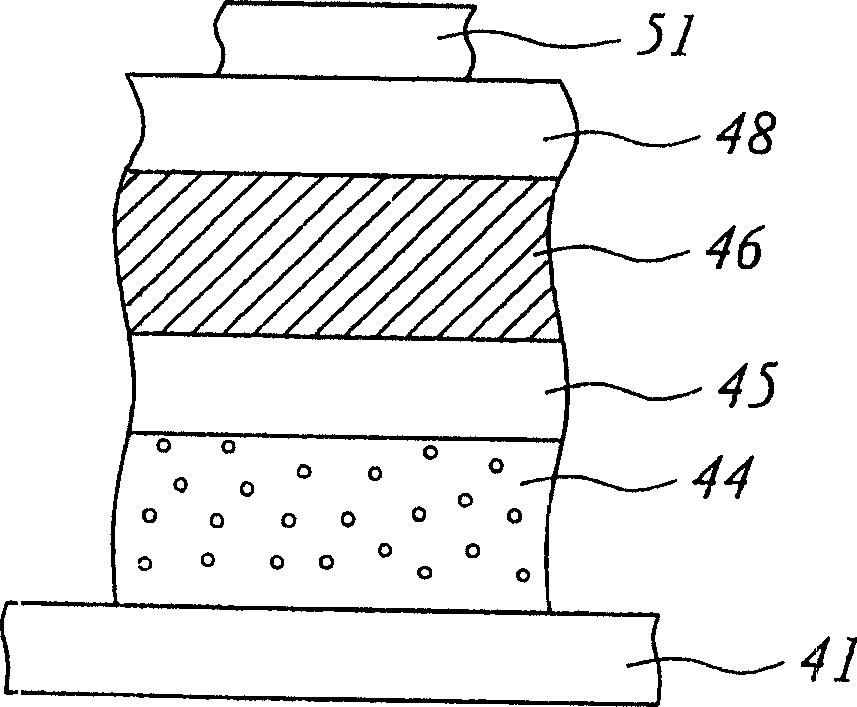

[0036] The structure of two groups of control groups and the structure of an embodiment of the present invention are proposed below, and related experimental processes and results are proposed. The relationship between the relative luminescence (Relative Luminescence) and the operation time (Operational Time) of the three groups of component structures is as follows: image 3 shown. The relationship between the driving voltage (Voltages) and the operating time (Operational Time) of the three-group element structure is as follows: Figure 4 shown.

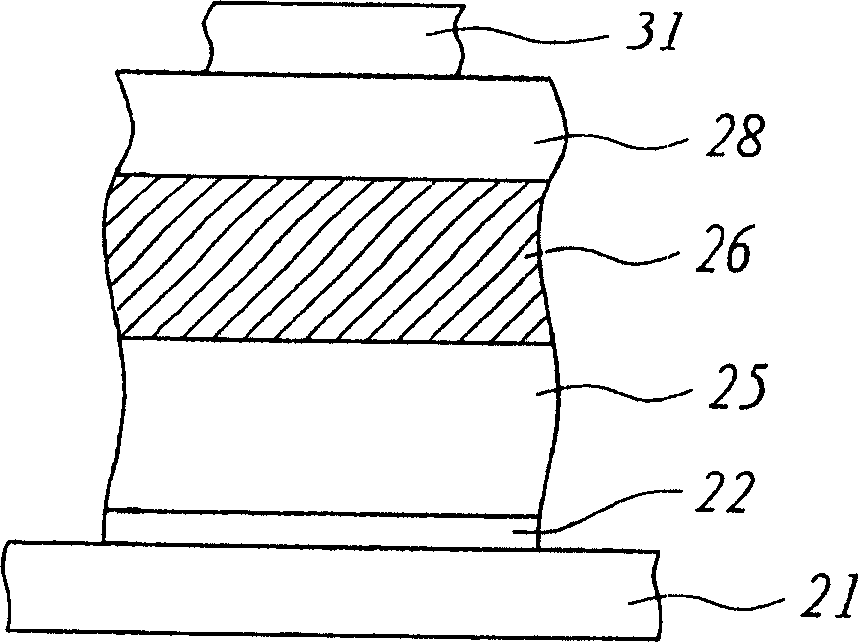

[0037] first control group

[0038] Figure 2A It is a schematic structural diagram of the organic light-emitting display element of the first control group of the present invention. First, ITO is provided and subjected to UV ozone treatment to form the anode 21 . A carbon fluoride (CFx) film is then formed on the anode 10 by plasma deposition to serve as the hole injection layer 22 . Then NPB is evaporated on the hole injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com