Visual sense addressing location full automatic explosion proof quantitative type liquid state metering and filling device

A technology of addressing, positioning and filling devices, which is applied in the directions of automatic packaging control, packaging, liquid materials, etc., can solve the problems of auxiliary time affecting work efficiency, automatic positioning cannot be realized, and containers cannot be compatible, etc., so as to shorten auxiliary time, Effects of expanding application range and field of use and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

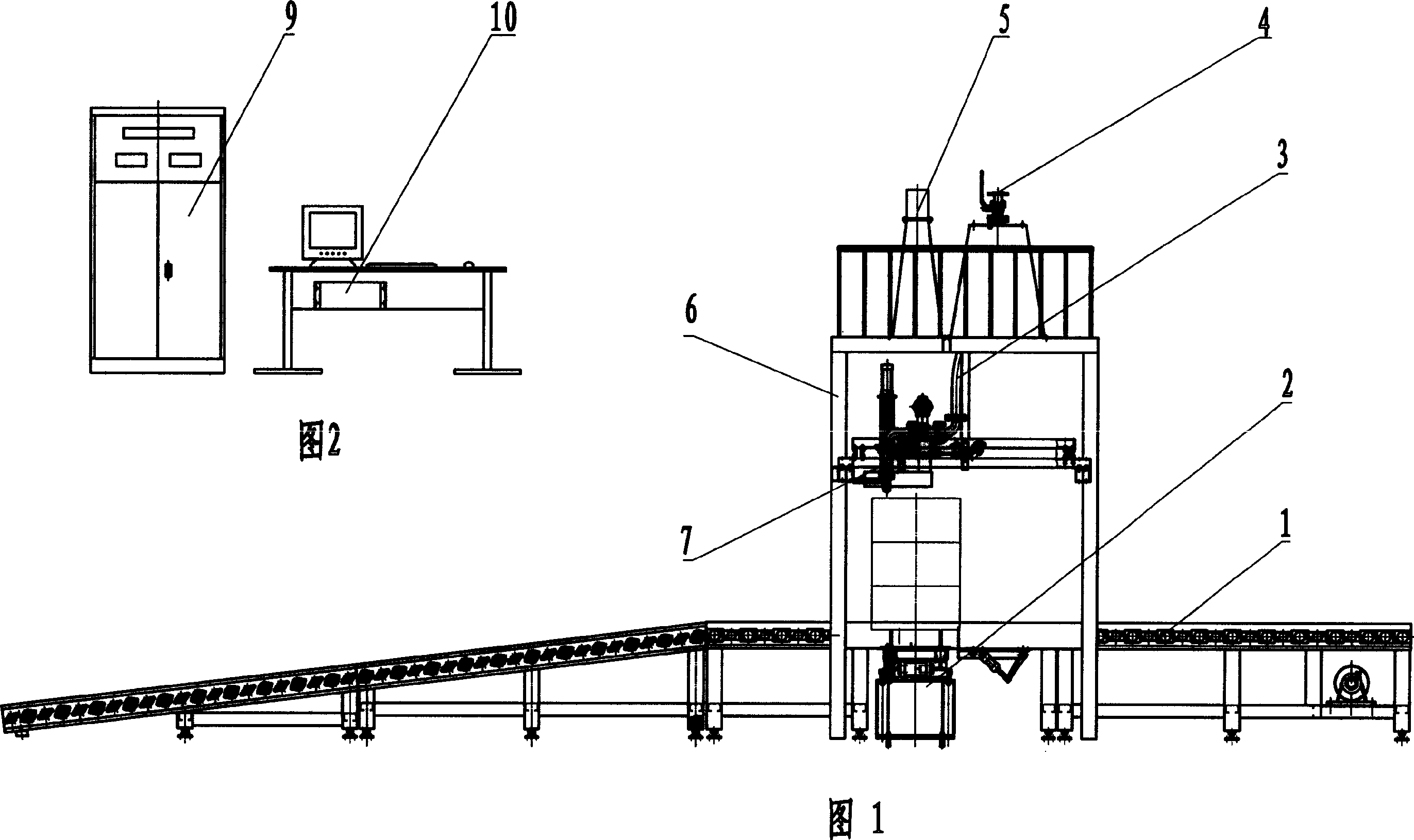

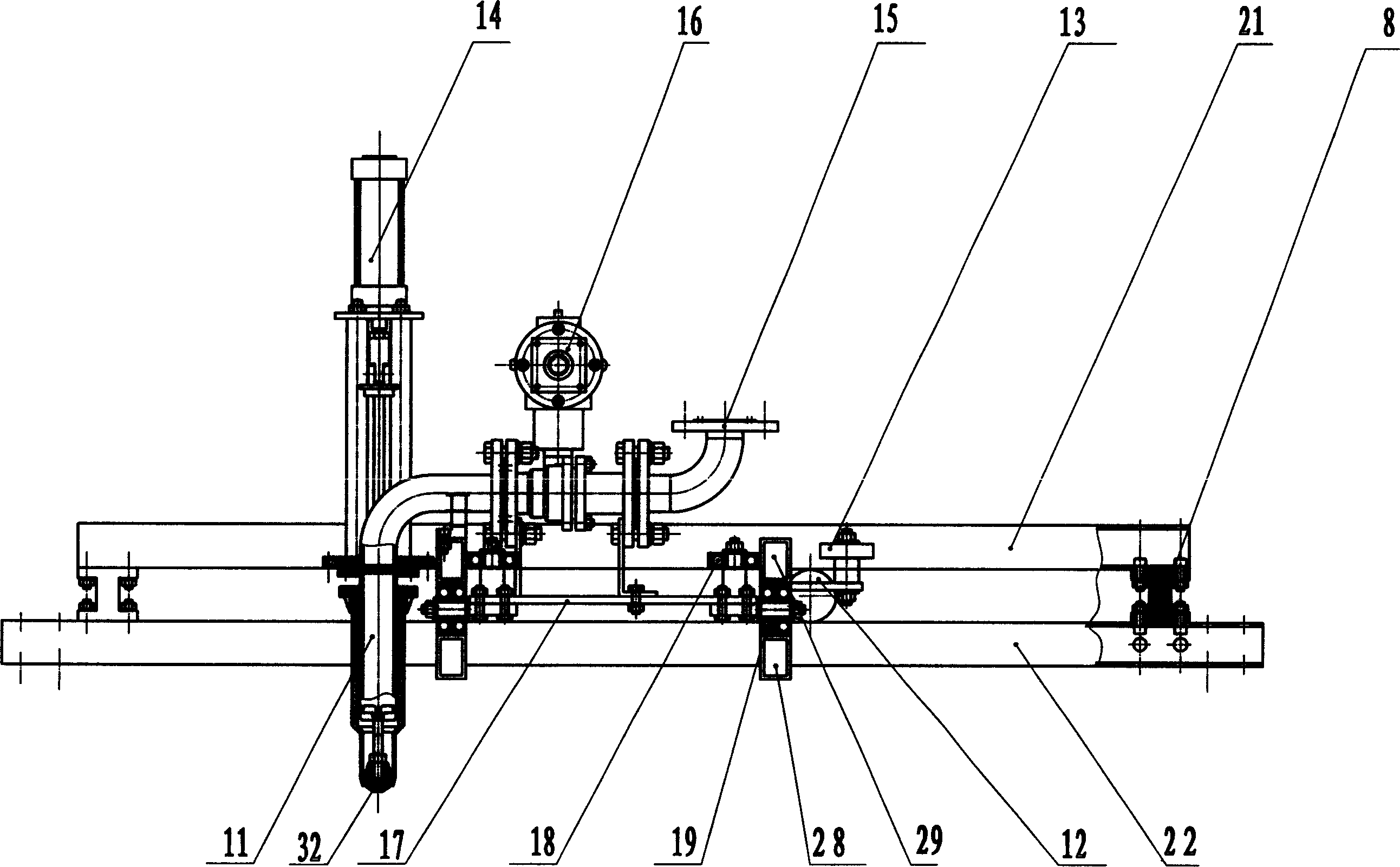

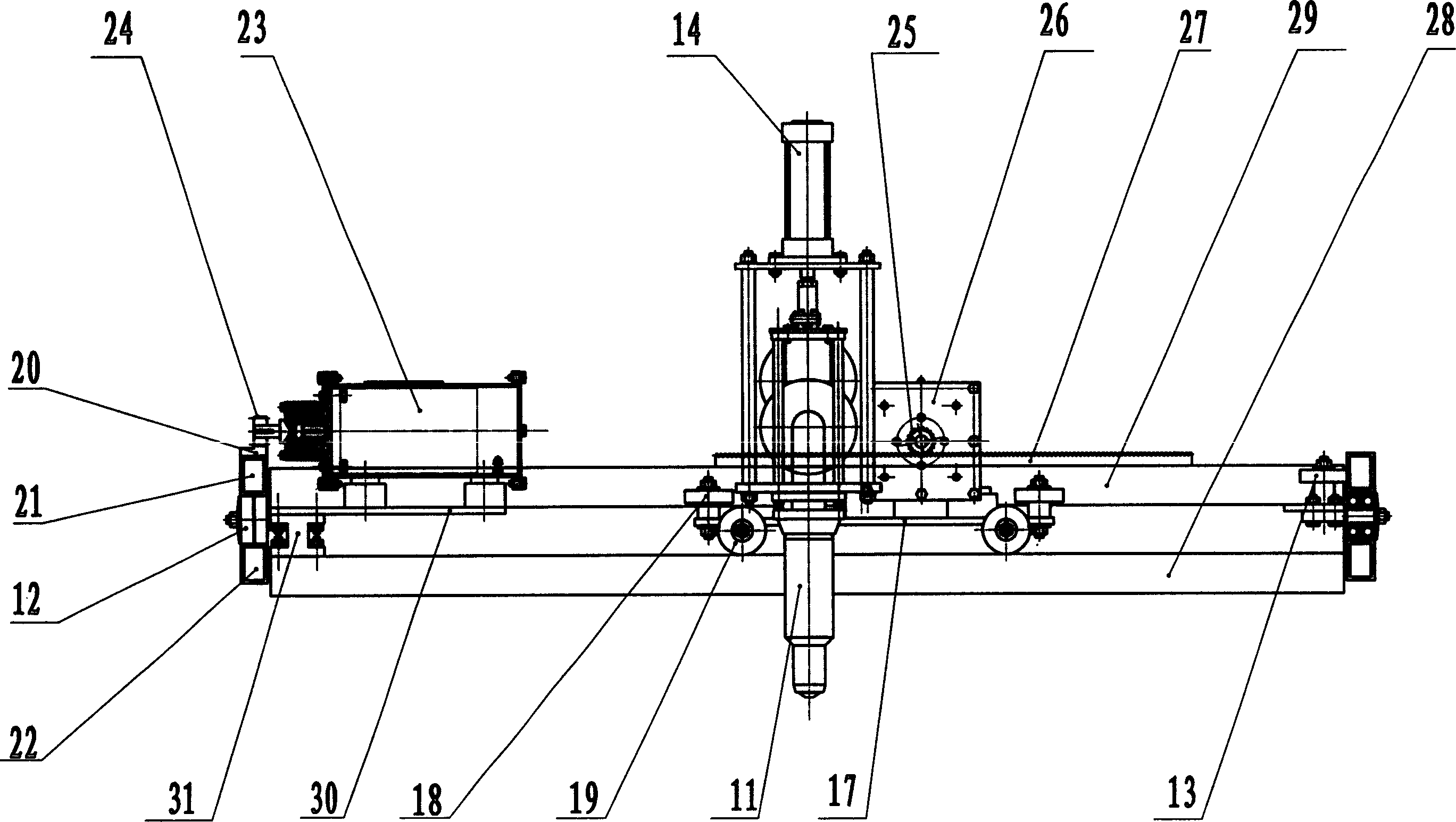

[0015] As shown in the figure, the invention includes: a body 6, a transmission mechanism 1, an automatic weighing and measuring mechanism 2, an automatic filling mechanism 7, and a visual addressing and positioning mechanism. , the data processing unit 10 that is connected with the electric eye 5, the automatic control unit 9 that is connected with the data processing unit 10 and a group of stepper motors controlled by it, and the automatic charging mechanism that is controlled by this group of stepper motors. Composed of sliding pallets and brackets. Said one group of stepper motors is made up of horizontal stepper motor 23 and vertical stepper motor 26; Said bracket is made up of two upper brackets 29 and two lower brackets 28, upper, The lower bracket is fixed by the bracket support 31, and the bracket is rollingly connected with the lower beam 22 of the body between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com