Device for on line measuring high temperatare fused body surface temsion, contact angle and density

A technology of surface tension and high-temperature melt, which is applied in the direction of measuring devices, surface tension analysis, instruments, etc., can solve the problems of long measurement time, easy distortion of photos, and many human factors, and achieve high degree of automation, simple and reliable operation , the effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

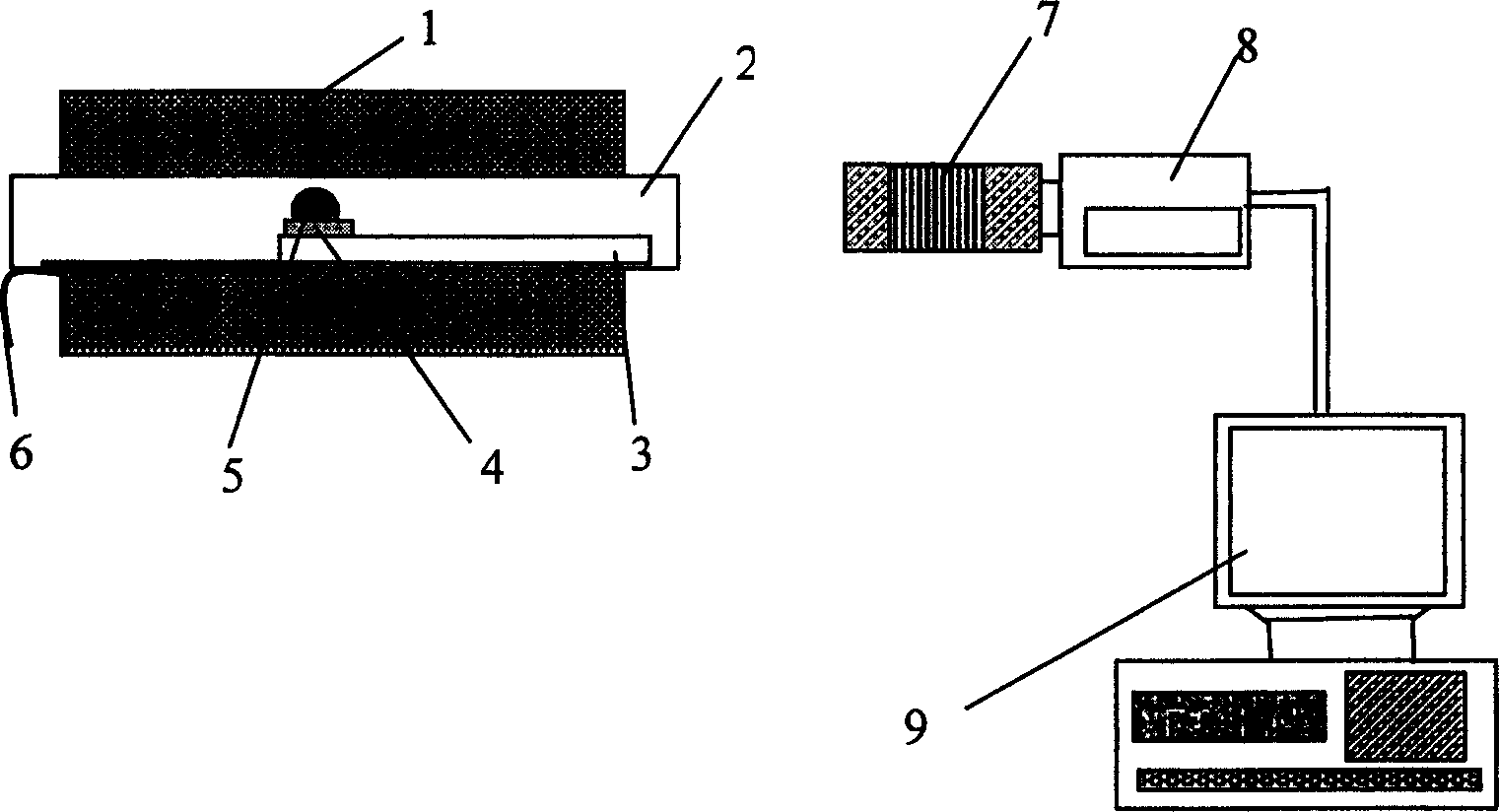

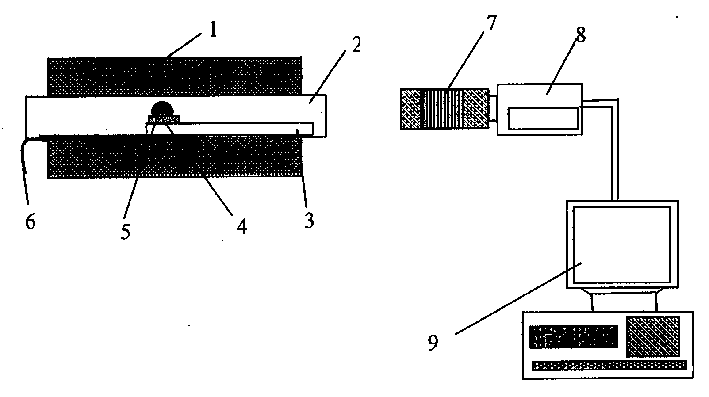

[0016] Such as figure 2 As shown, the observation part is composed of a camera 8 and a computer 9. The camera 8 is a Nikon D100 single-lens reflex digital camera, and the adjustable focal length of its original lens is between 24-85mm. In order to adapt to the observation of high-temperature melt, the lens of camera 8 is replaced by CCD lens 7 of model 180mmf / 2.8ED in this system. The resolution of this lens is 6.1 million pixels, and the adjustable focal length is between 50-1500mm . Connect with leather tiger between CCD lens 7 and camera 8, and CCD lens 7 has loaded optical filter and filter. The camera 8 is connected with the computer 9 through a USB port.

[0017] The high-temperature melting device part includes a carbon tube high-temperature furnace tube 1 and a quartz sealing sleeve 2, and the quartz sealing sleeve 2 is pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com