Acceleration sensor

An acceleration sensor, acceleration sensing technology, applied in the direction of measuring acceleration, speed/acceleration/impact measurement, acceleration measurement using inertial force, etc., can solve problems such as the change of acceleration sensor characteristics, and achieve the effect of preventing characteristic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments according to the present invention will be described below with reference to the drawings.

[0034] Implementation form 1:

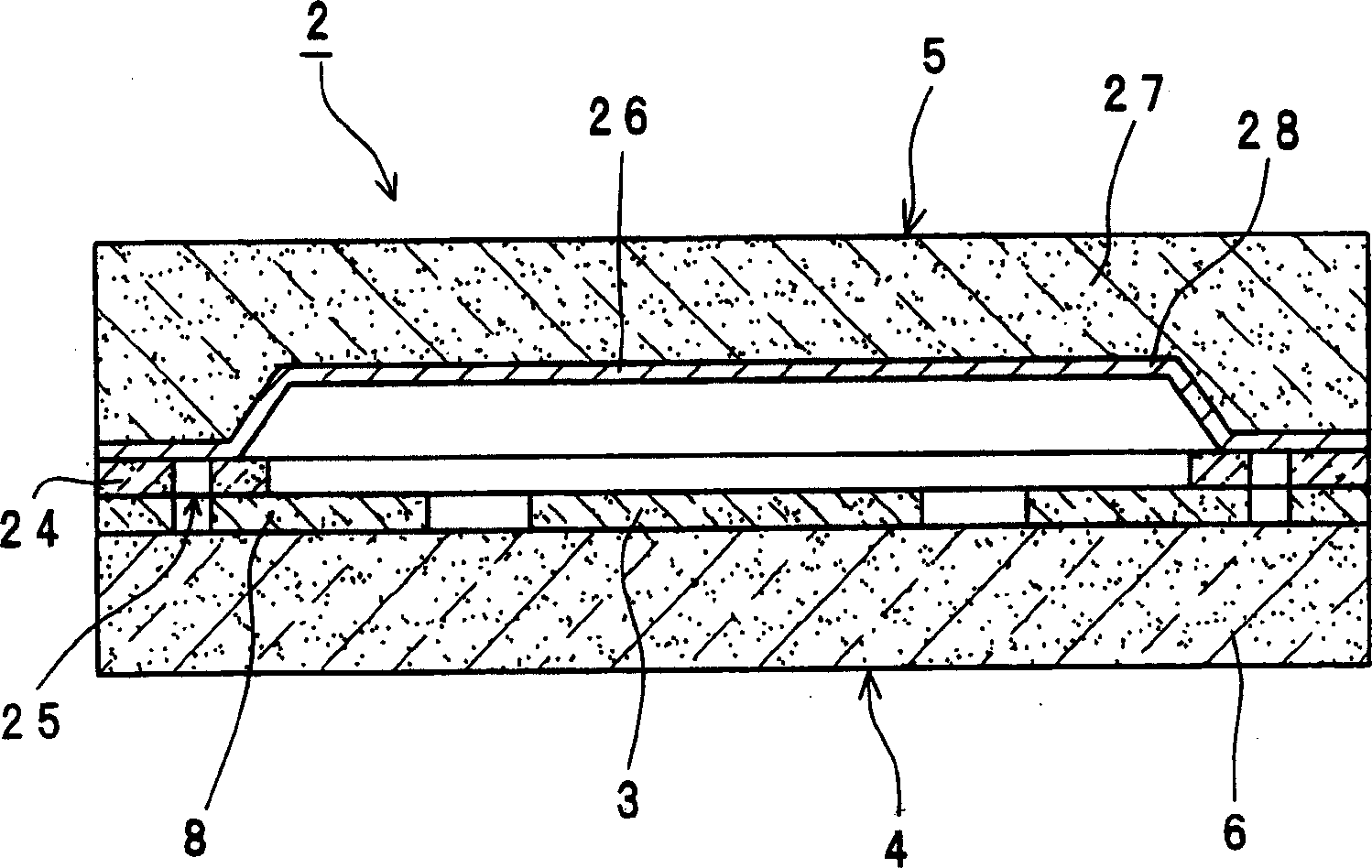

[0035] figure 1 It is a cross-sectional view of Embodiment 1 according to the present invention. The acceleration sensor 2 includes a base portion 4 for carrying the acceleration sensor element 3 , and a cover portion 5 joined to the base portion 4 for sealing the acceleration sensor element 3 .

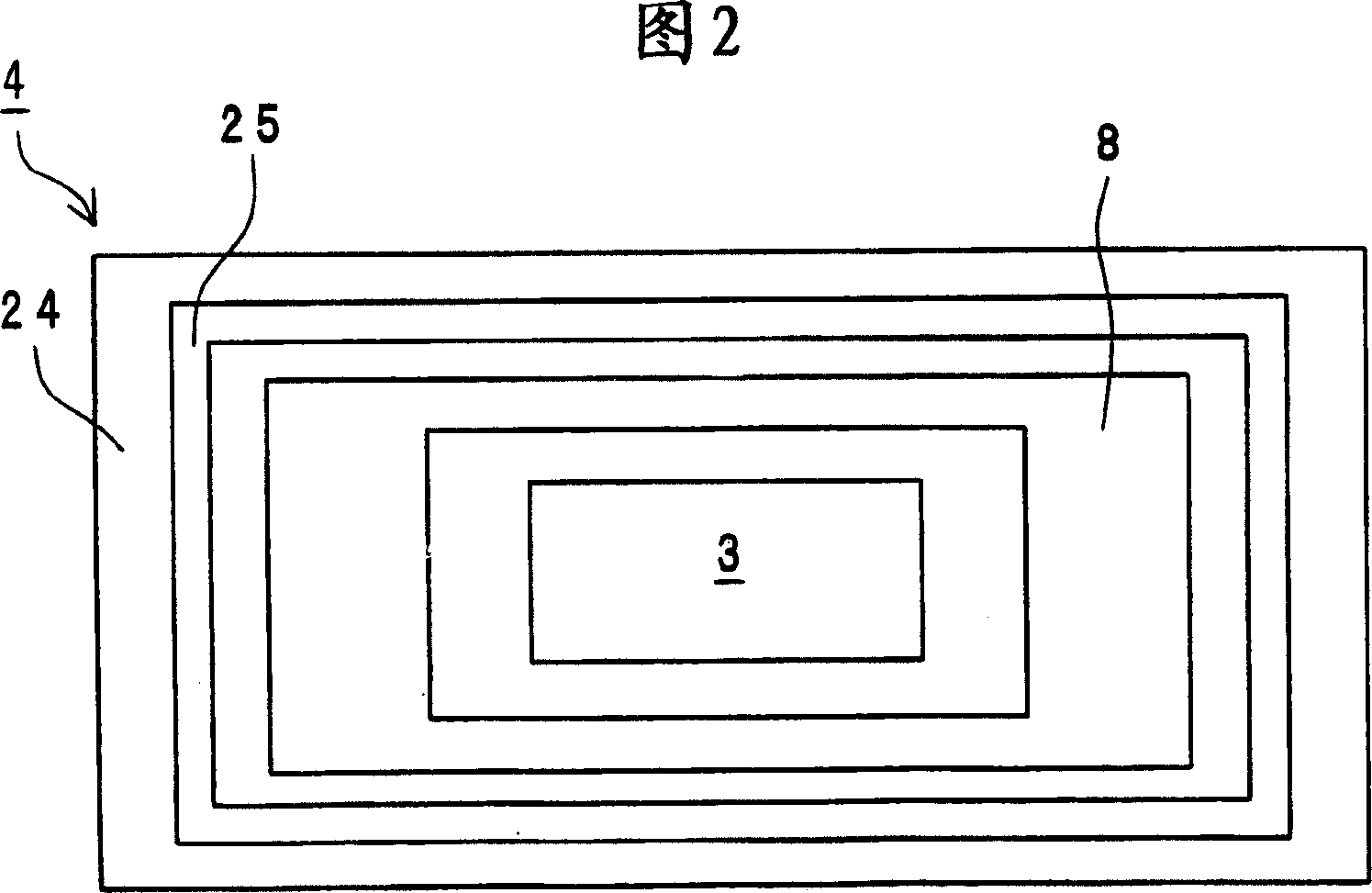

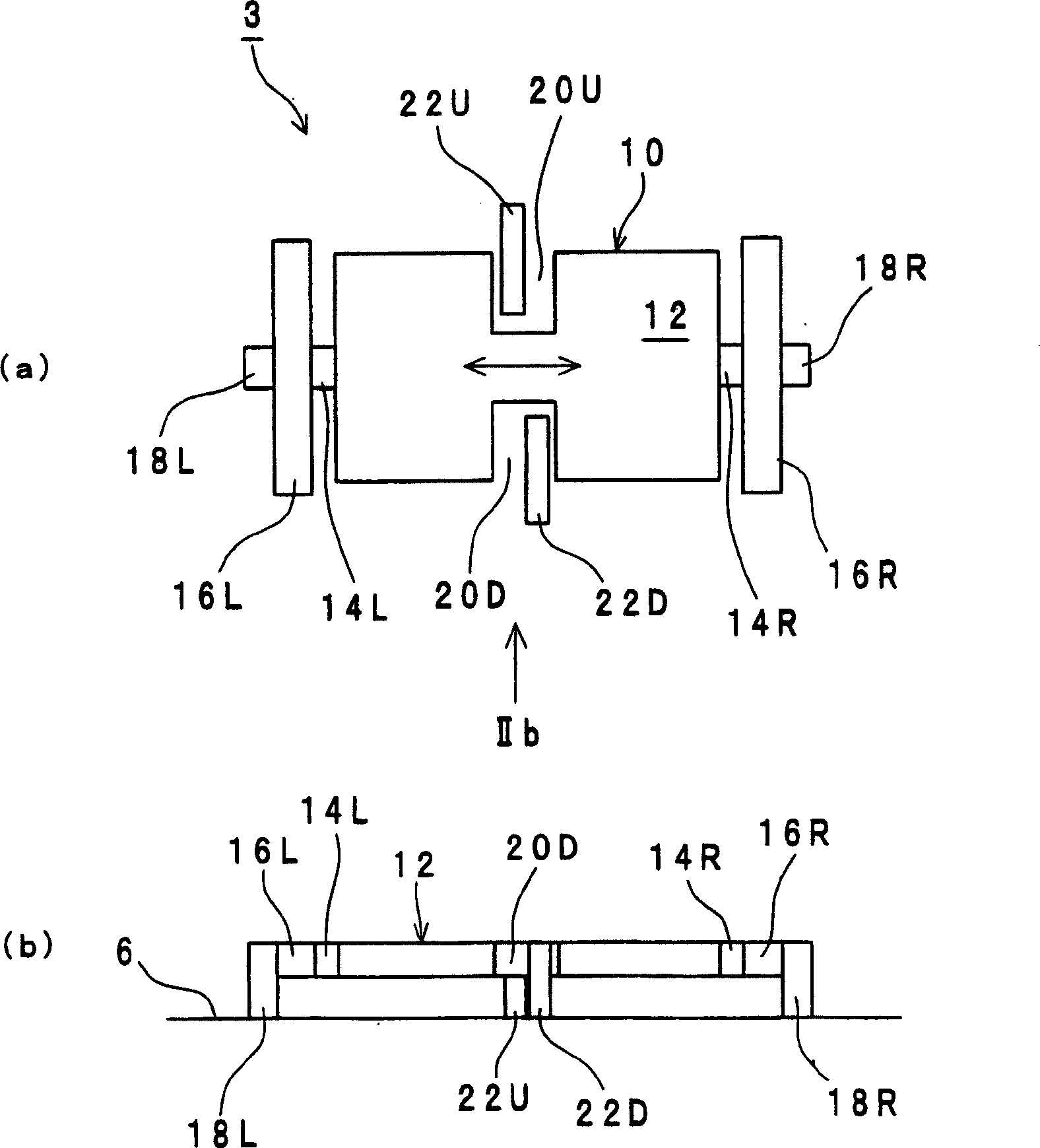

[0036] FIG. 2 is a plan view of the base portion 4 . The base portion 4 is provided with a rectangular semiconductor silicon substrate 6 (a substrate in a broad sense), on the principal surface of which, a sensor element 3 for detecting acceleration and a frame 8 surrounding the sensor element 3 are provided. The frame 8 is generally rectangular, and the invention is not limited by its shape. The acceleration sensing element 3 and the frame 8 are formed, for example, by depositing a polysilicon layer doped with phosphorus as an impurity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com