Method for manufacturing stamper, stamper and optical recording medium

A stamper and plasma technology, which is used in the field of manufacturing stampers, stampers and optical recording media, can solve the problems of reduced electrical conductivity, environmental problems, and reduced formation rate of electroformed thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] (1)

[0051] Examination of the dependence of the input power with respect to the etching process The experiments used to determine the etching conditions are described. Note that since the time dependence during etching is not critical, it is assumed to be constant at 90 s.

[0052] The results are shown in Table 1.

[0053] [Table 1]

[0054] Etched Input Power (W) Separability Noise (dBm)

[0055] 10 Poor N / A

[0056] 30 Poor N / A

[0057] 50 good -71

[0058] 200 good -73

[0059] 500 good -72

[0060] 600 good -68

[0061] 800 good -65

[0062] 1000 good -58

[0063] In Table 1, the term "poor" in the column of separability indicates an etching condition under which the electroformed film (II) 107 cannot be separated from the parent stamper 106, or indicates that defects are generated on the electroformed film (II) 107 conditions of. The term "good" in the same column indicates the condition that the mother stamper 108 without defe...

example 2

[0078] (1)

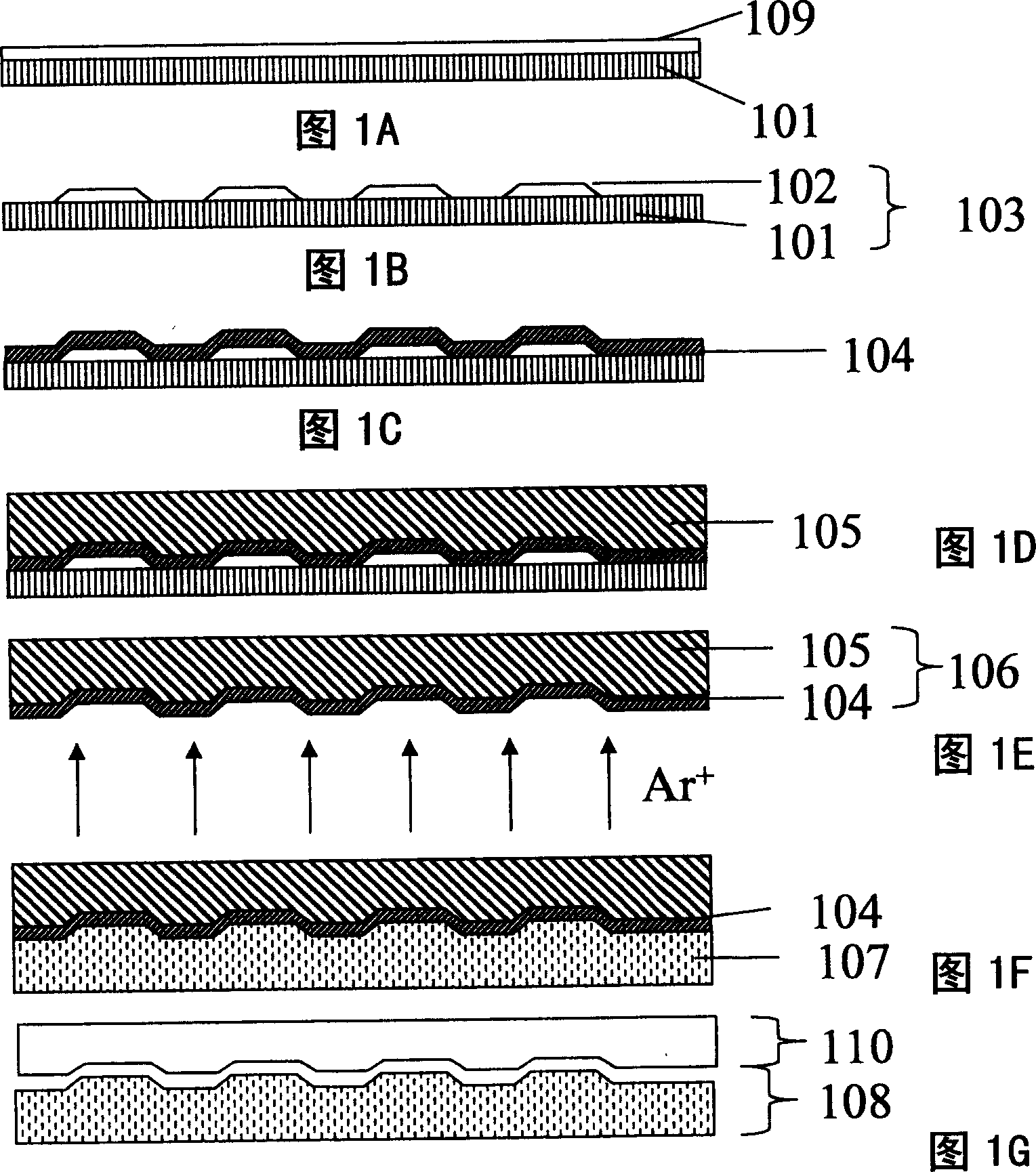

[0079] In Example 2, the master mold 108 will be formed through the same steps and processes as described above. Figure 1 will be used to describe this.

[0080] It is conceivable that there is a relationship between the separability of the mother stamper 108 , the presence of defects on the stamper, and whether nickel hydroxide can be uniformly formed on the parent stamper 106 . In order to form hydroxide uniformly on the stamper, it is necessary to immerse the stamper in water immediately after the plasma surface treatment. Conversely, after processing, if the parent stamper 106 is left in the atmosphere, nickel oxide and nickel hydroxide are produced. Since the ratio of nickel oxide to nickel hydroxide is locally different, and the separability of these materials is different, the difference in separability may locally occur, and the possibility that defects remain on the mother stamper 108 increases.

[0081] In Table 3, the relationship between the time th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com