Laser pattern impression producing technique

A production process, laser technology, applied in printing, copying/marking methods, burning, etc., can solve the problems of laser transparent film and printed matter not easy to peel off, laser anti-counterfeiting pattern deformation, printed matter surface blistering, etc., to avoid malfunction , the cooling range is large, and the effect of preventing surface foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

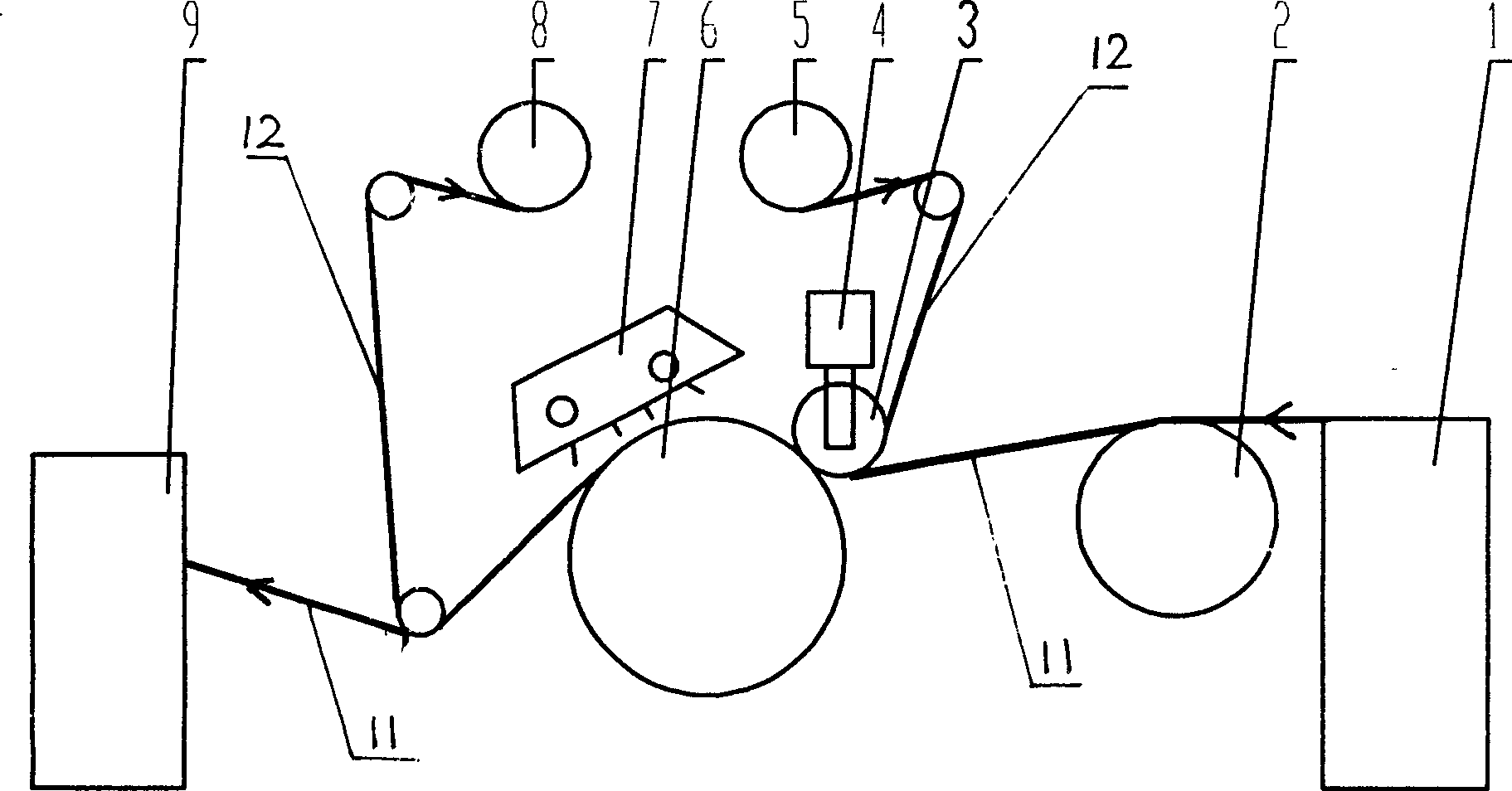

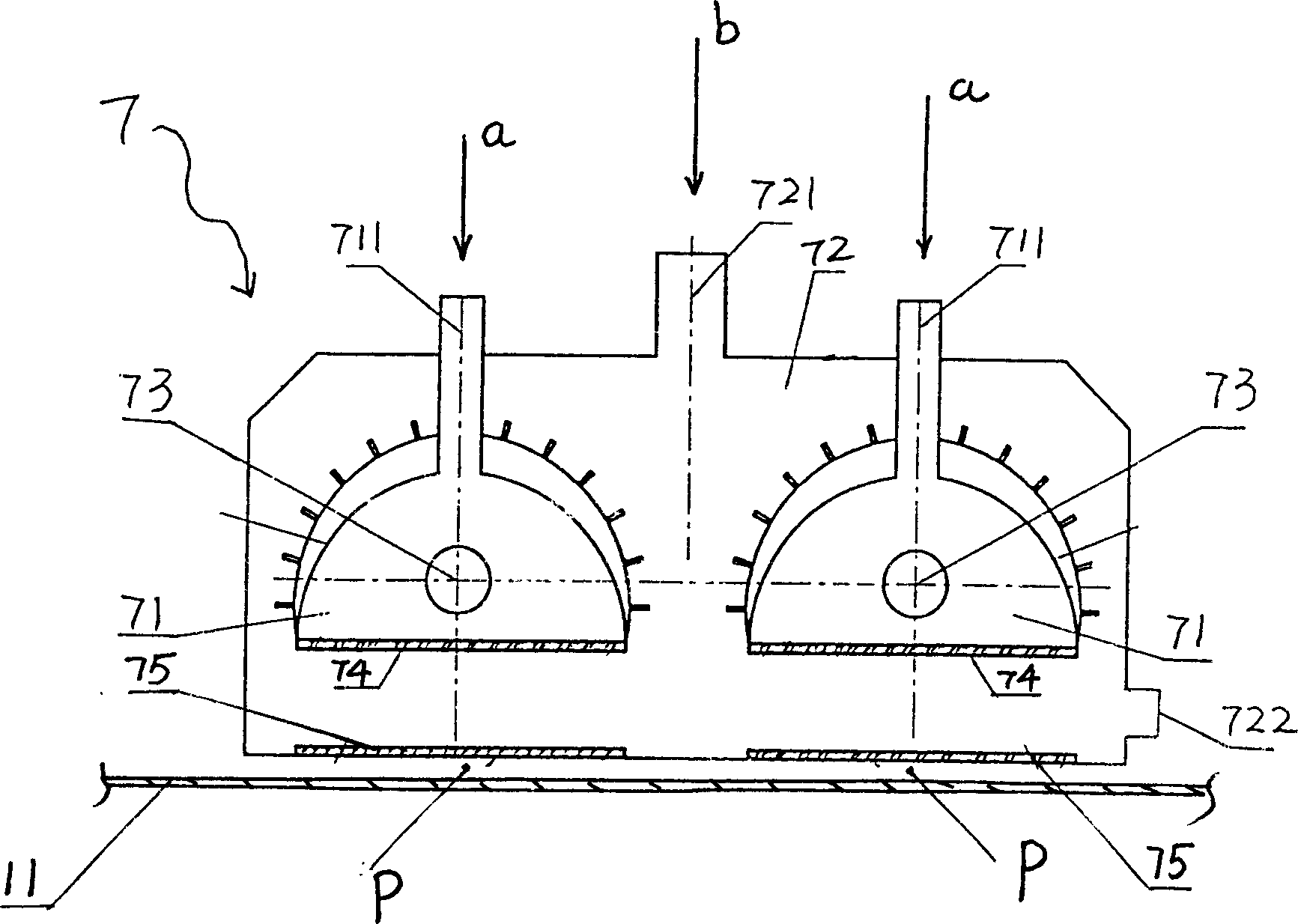

[0016] figure 1 The process flow shown is as follows: ①, the printed matter 11 is placed on the printed matter conveying mechanism 1, and the laser transparent film 12 is installed on the laser film unwinding mechanism 5; ②, the ultraviolet varnish coating mechanism 2 is coated on the surface of the printed matter 11 One layer of UV varnish; ③, large turning roller 6 and embossing roller 3 press the side of the laser transparent film 12 with the embossed surface pattern and the side of the printed matter 11 coated with UV varnish, so that the embossing of the laser transparent film 12 The texture pattern is embossed on the ultraviolet varnish layer of the printed matter 11, and the pressure of the embossing roller 3 is controlled by the cylinder 4; ④, utilize the ultraviolet lamp in the curing box 7 to irradiate the printed matter, so that the printed matter 11 is embossed with the ultraviolet varnish layer of the laser pattern Curing; ⑤, the laser transparent film 12 that was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com