Method for producing wear-resisting impervious concrete with activated powdered coal

A cement and pulverized coal technology, applied in cement production, clinker production, etc., can solve the problems of easy lime sand, non-wear resistance, and foaming on the concrete surface, so as to improve the quality of cement and concrete, and avoid surface foaming and delamination, reducing the effect of producing finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

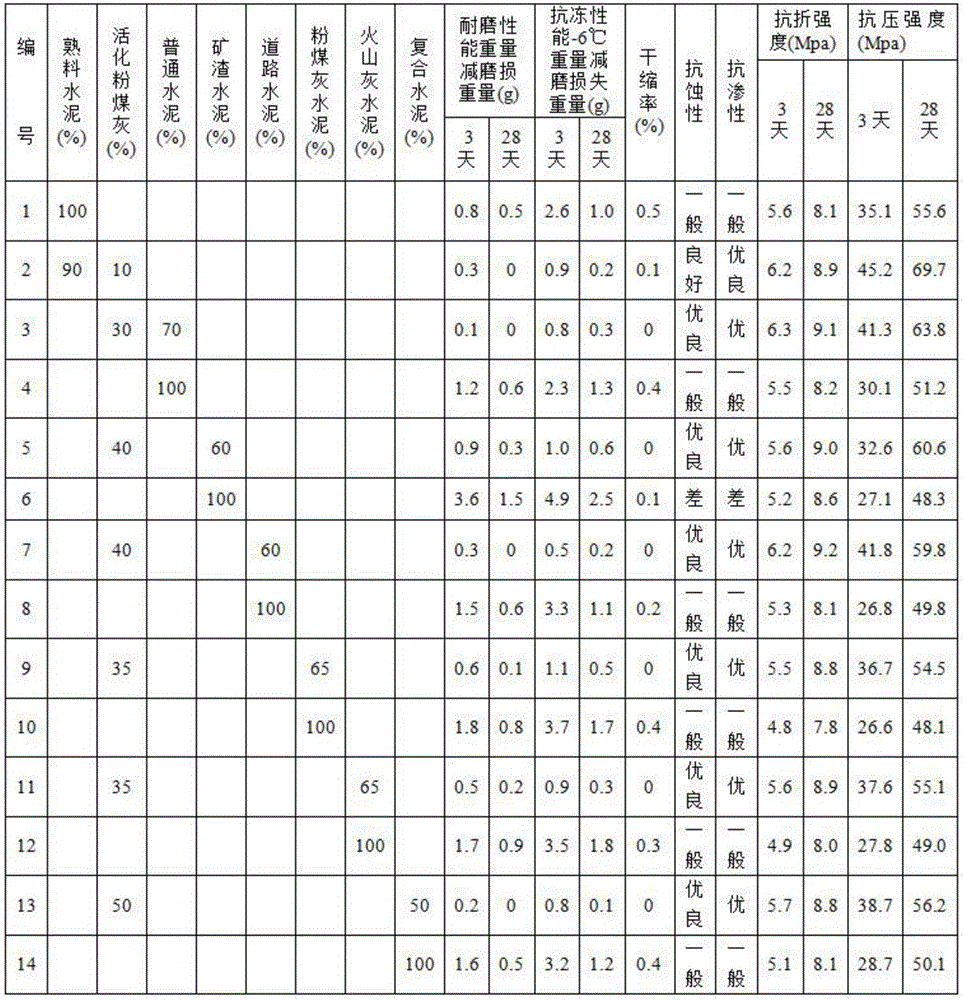

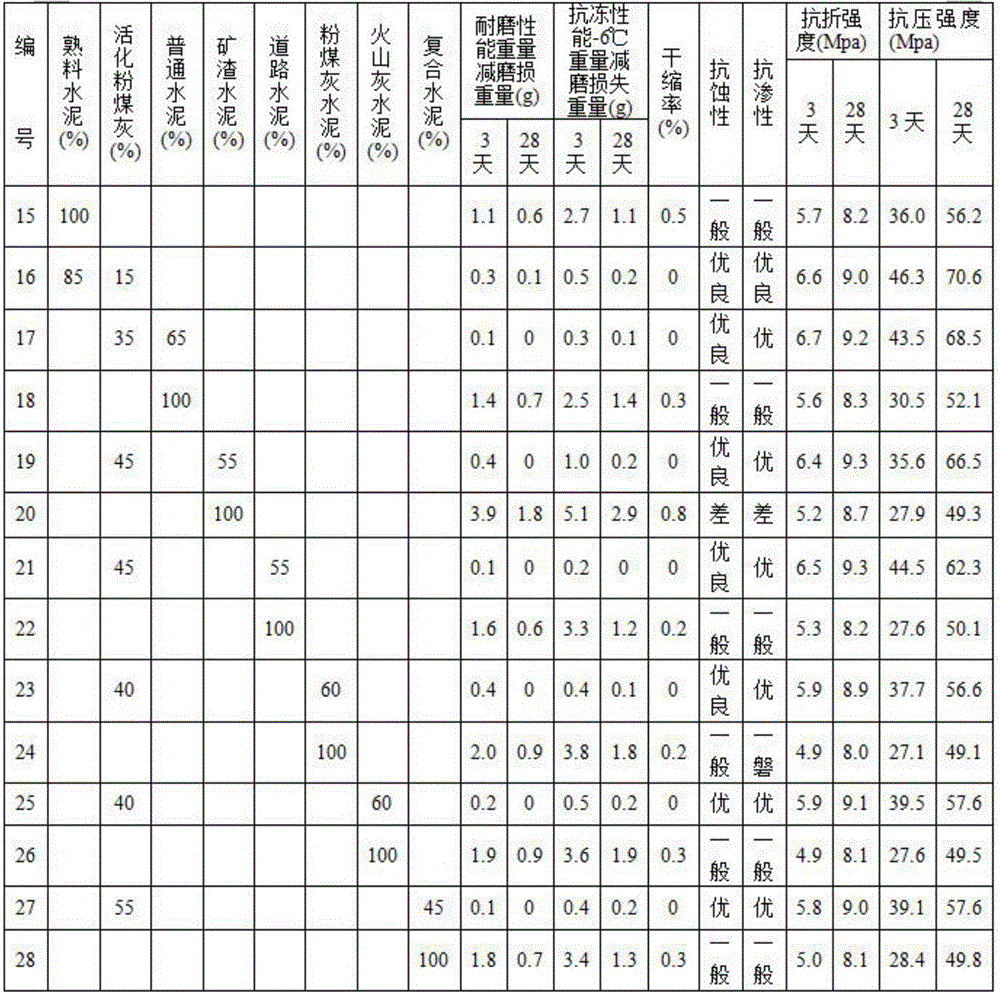

Examples

Embodiment 1

[0014] Embodiment one, a kind of method of producing wear-resistant and anti-seepage cement with activated pulverized coal, the steps of this production method are as follows:

[0015] S1. Material preparation: The raw materials are fly ash and alkali slag. The fly ash is used in power plants to generate electricity by burning coal. The dry and wet waste slag discharged later is called fly ash. The alkali slag used is the waste slag discharged from the salt chemical industry alkali .

[0016] S2. Dosing and molding: After mixing the fly ash 65% by weight and the alkali slag 35% evenly, add an appropriate amount of water to fully stir to make an activated mixture or a briquette for later use.

[0017] S3. Activation, solidification and drying: the activated mixture or blocks are stacked and dried naturally, and the free water content of the activated mixture or blocks after curing and drying should be controlled within 1-5%, and the activated fly ash product is obtained.

[00...

Embodiment 2

[0023] Embodiment two, a kind of method of producing wear-resistant and anti-seepage cement with activated pulverized coal, the steps of this production method are as follows:

[0024] S1. Material preparation: The raw materials are fly ash and alkali slag. The fly ash is used in power plants to generate electricity by burning coal. The dry and wet waste slag discharged later is called fly ash. The alkali slag used is the waste slag discharged from the salt chemical industry alkali .

[0025] S2. Dosing and molding: After mixing the fly ash 75% by weight and the alkali slag 25% evenly, add an appropriate amount of water to fully stir to make an activated mixture or a briquette for later use.

[0026] S3. Activation, solidification and drying: the activated mixture or blocks are stacked and dried naturally, and the free water content of the activated mixture or blocks after curing and drying should be controlled within 1-5%, and the activated fly ash product is obtained.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com