Method for stabilizing blast furnace operation based on equilibrium point

A blast furnace operation and balance point technology, which is applied in the field of stable blast furnace operation and stable blast furnace operation based on the balance point, can solve problems such as inactive blast furnace hearth, inability to summarize changes in blast furnace, and thick furnace walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following provides specific embodiments in conjunction with the contents of the accompanying drawings and methods:

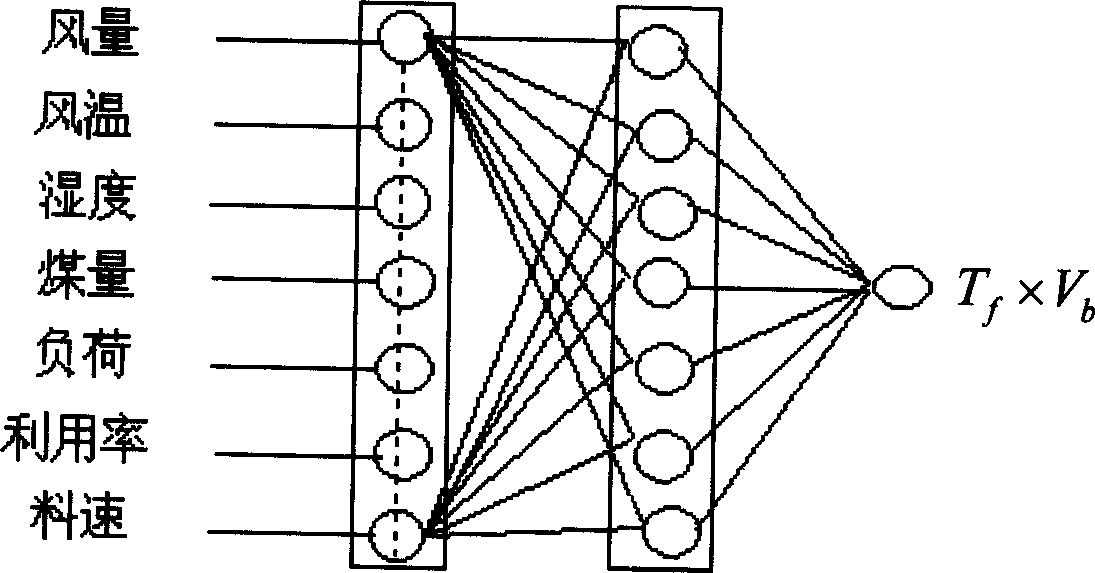

[0063] Example Ma Steel 2500m 3 Blast Furnace Balance Point Operation Method

[0064] First Tsushima Steel 2500m 3 The field operation data of No. blast furnace from 1996 to 1997 has been screened as necessary. Considering that the balance point operation of the blast furnace is established to maintain the normal furnace condition, the operation day data of the following situations are discarded and not used: 1) If the number of sliding materials exceeds two times, 2) The blast furnace utilization factor is less than 2.0t / day.m 3 3) If the shutdown time exceeds 1 hour, according to the above principles, obtain useful data reflecting the normal production status of the blast furnace. According to the above principles, a total of 533 groups of available data are obtained, which can basically reflect the normal production status of the blast furnace; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com