Three dimensional anchor cable bolting technology in heading

An anchor cable net and roadway technology, used in the installation of bolts, mining equipment, earthwork drilling and other directions, can solve the problems of support failure, low tensile strength of coal and rock, loss, etc., to increase reliability and safety, The effect of avoiding premature force damage and facilitating on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the utility model will be further described below in conjunction with accompanying drawing:

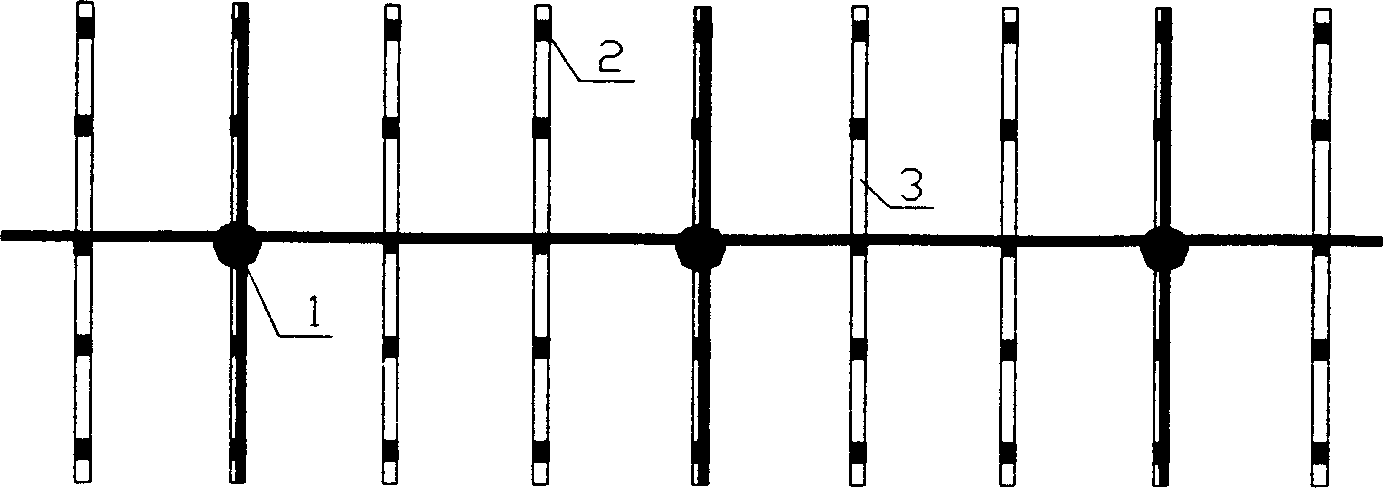

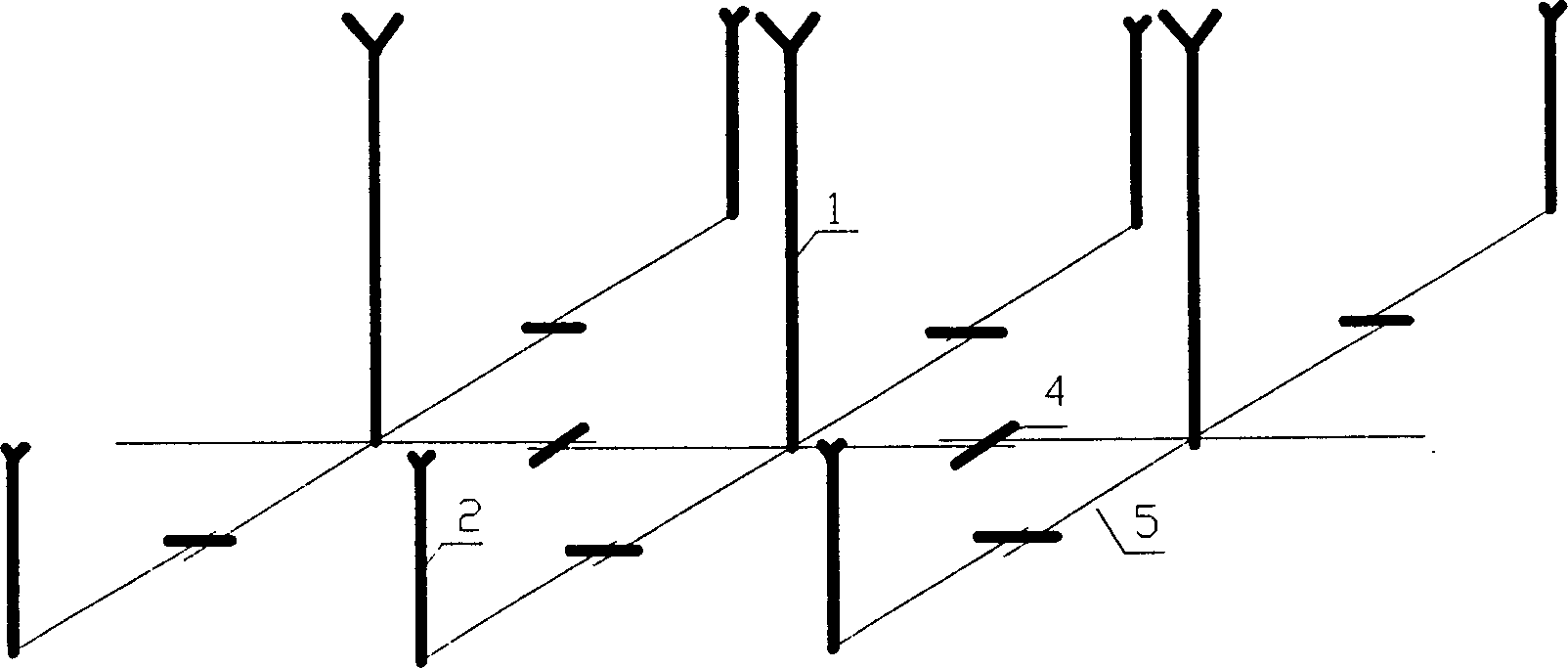

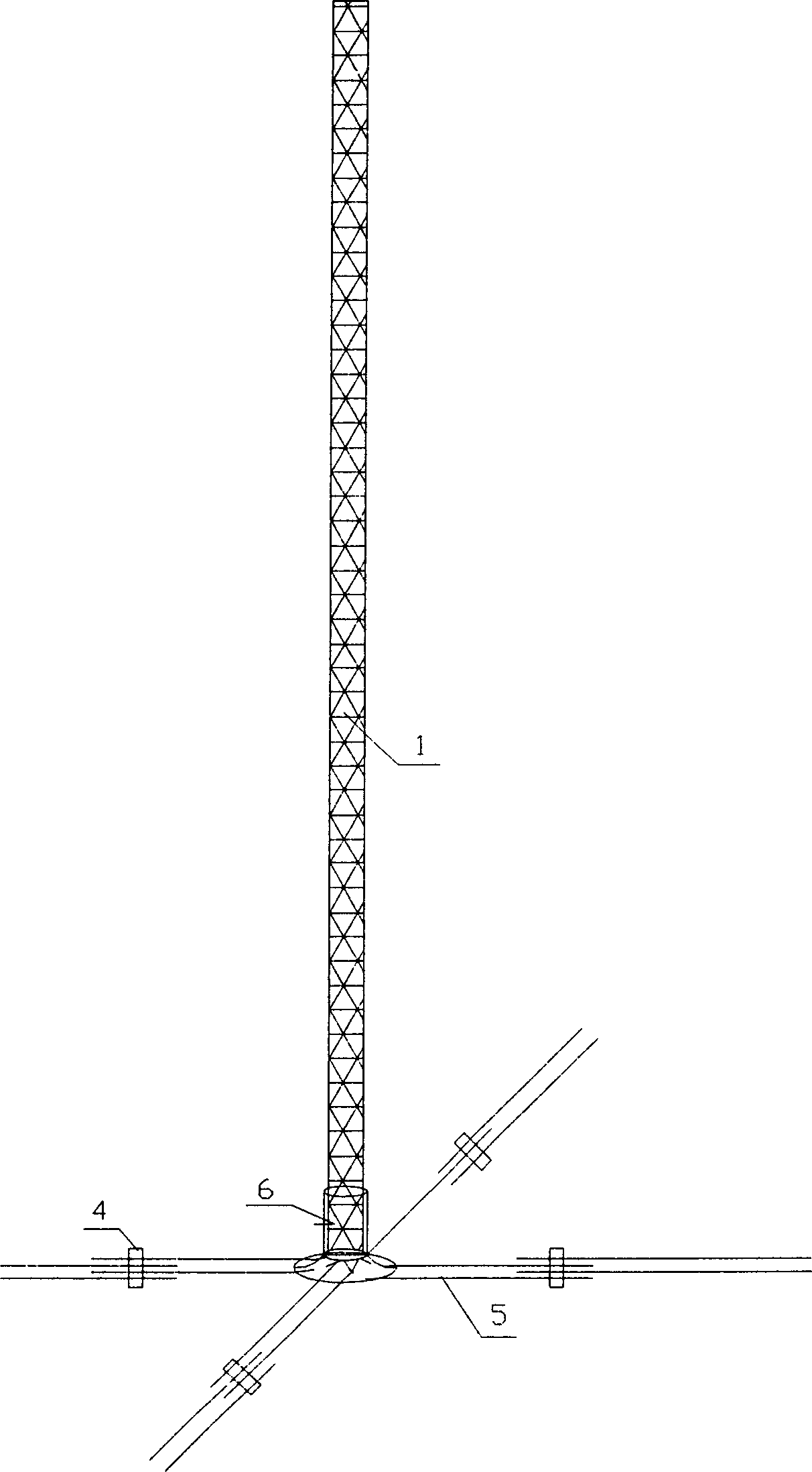

[0010] The three-dimensional anchor cable network support technology for coal seam roadway of the present invention, along the central axis of the roadway roof, anchor cables 1 are arranged in a single row at intervals to fix the roof strata, the round hole at the tail of the anchor cable 1 is covered with a bell mouth protection hole pipe 6, and the 7 at the tail of the anchor cable 1 A steel strand 5 protrudes from the hole protection pipe 6, separates along the cross direction of the horizontal plane, and connects with the two anchor rods 2 on the edge of the roof of the same row and the two adjacent anchor cables 1 respectively, so that the roof rock formation is protected. Three-way extrusion to improve its bearing capacity. The steel strand 5 is connected by a connector 4, which is a cylindrical steel sleeve with four holes, and the tail of the steel stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com