Pressure release device for oil well

A decompression device and oil well technology, which is applied to components of pumping devices for elastic fluids, wellbore/well components, and production fluids, etc., which can solve the problems of inconvenient maintenance, difficulty in adapting to oil wells with large and small gas volumes, and short service life And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

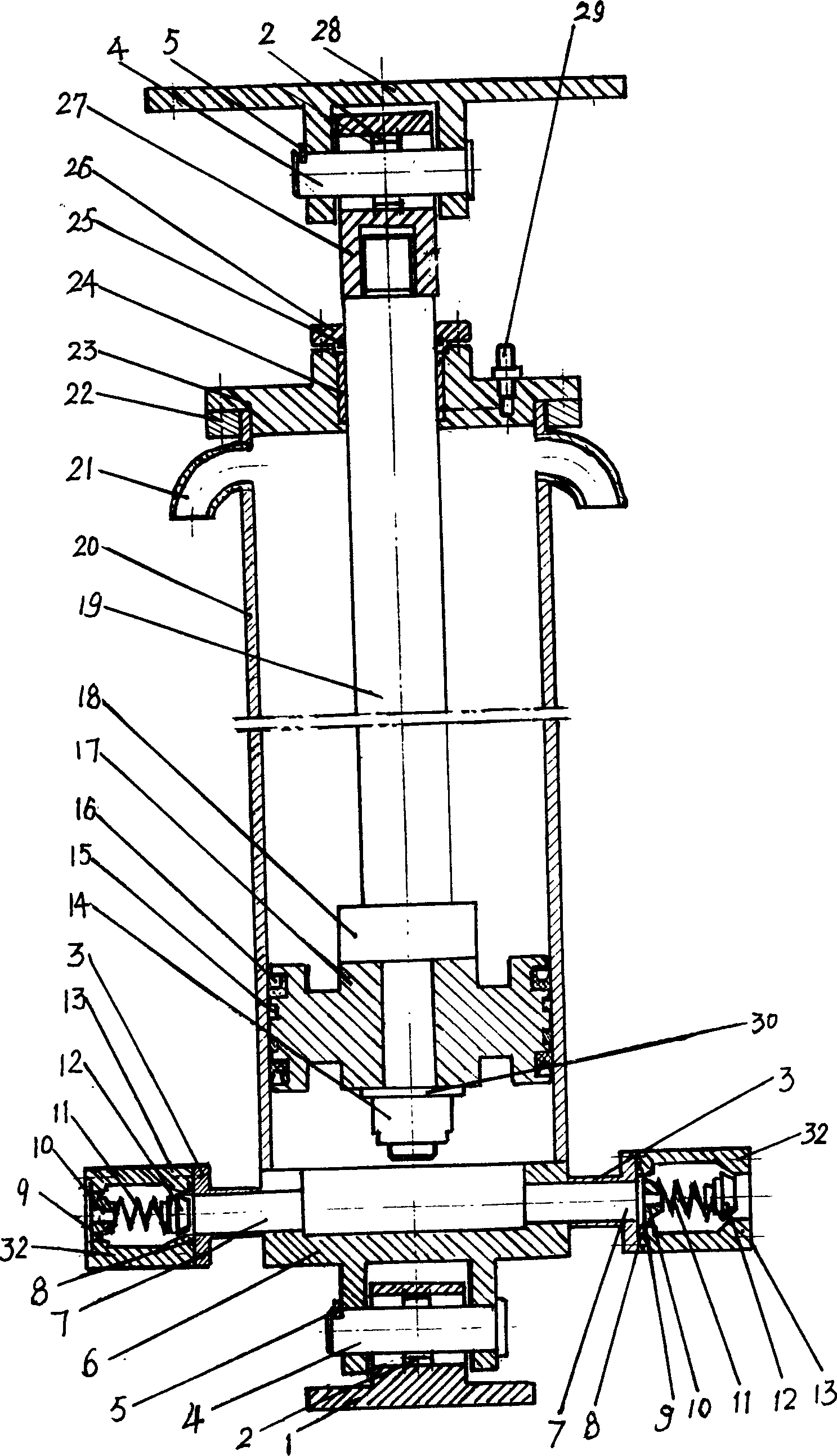

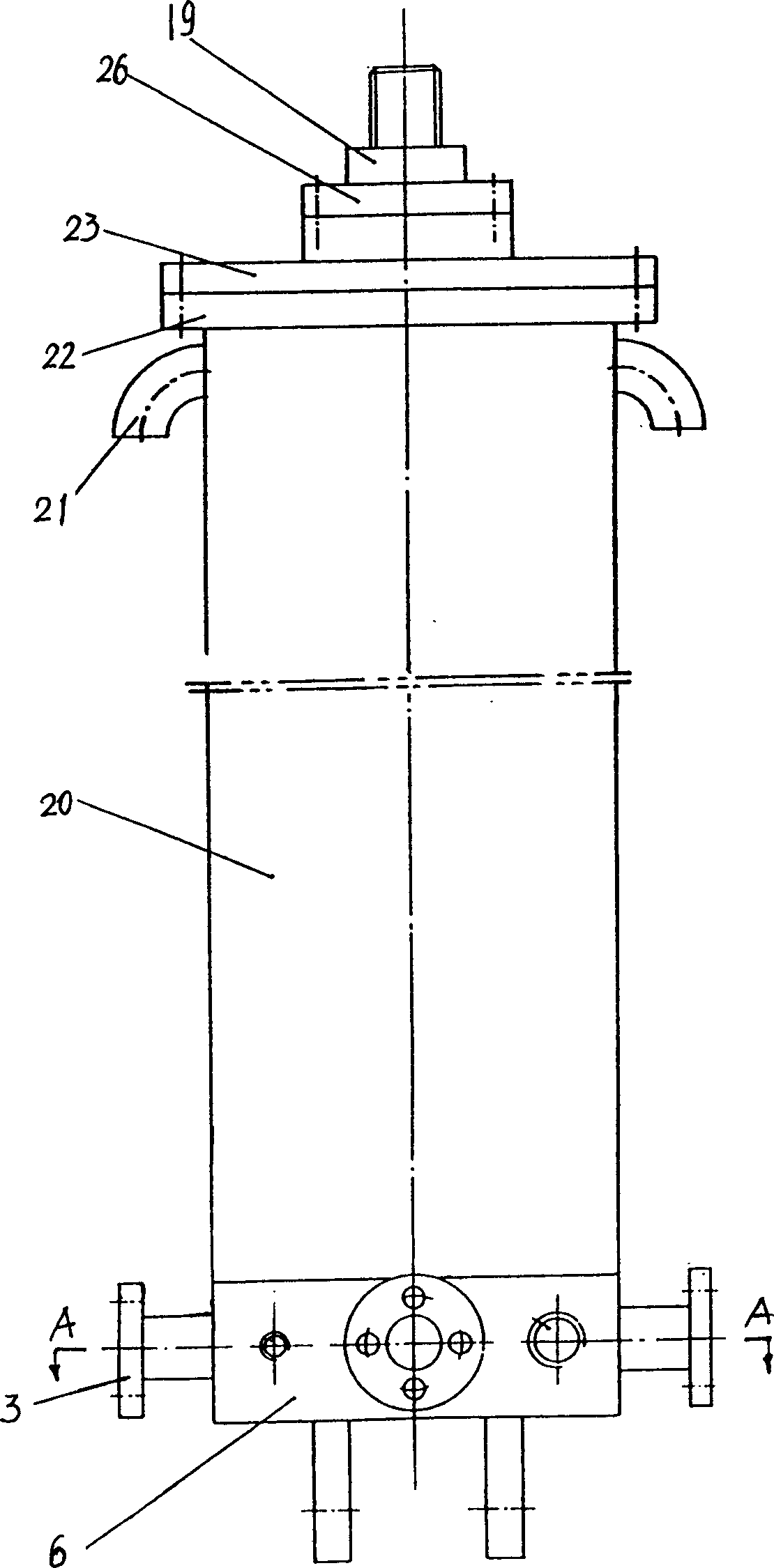

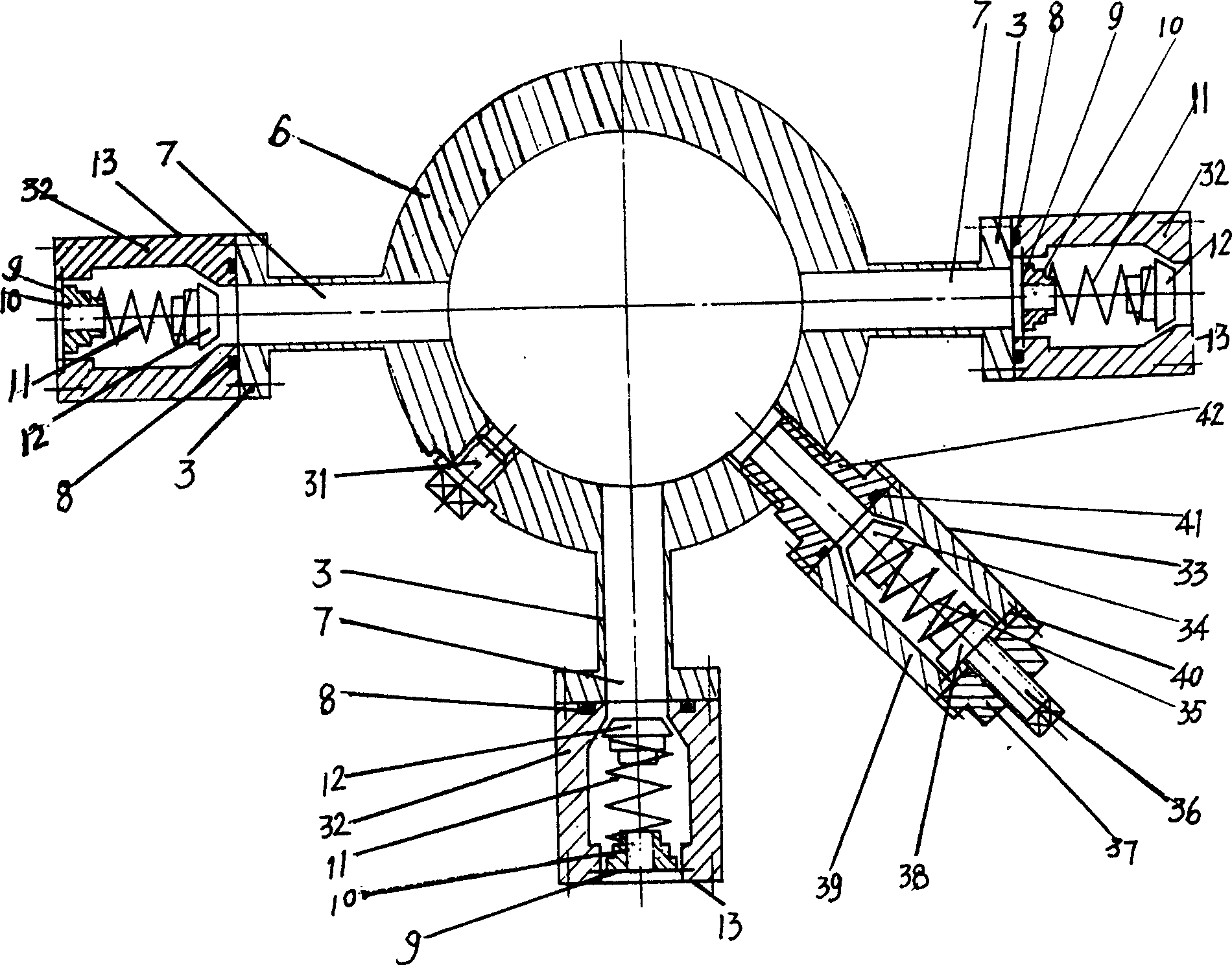

[0011] see Figure 1-Figure 3 , a kind of oil well decompression device, it is made of cylinder front cover 23, cylinder block 20, piston rod 19, piston 17, cylinder back cover 6, oil filling plug 29,31, has installation oil injection on the cover wall of cylinder front cover 23 The oil filling hole of the plug 29, the front end of the cylinder body 20 has an exhaust hole 21, the cylinder back cover 6 is equipped with a universal bearing 2 and a rear fixed plate 1, and the shaft pin 4 and the iron stopper 5 connect the rear fixed plate 1 with the cylinder back cover 6 Connected in one body, the front end of the piston rod 19 is threaded with the universal bearing sleeve 27, the universal bearing sleeve 27 is equipped with the universal bearing 2, the shaft pin 4 and the stopper 5 connect the front fixed plate 28 and the universal bearing sleeve 27 into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com