Microfabricated fluidic structures

A microfluidic and fluid technology, which is applied in fluid controllers, laboratory containers, chemical analysis using microanalysis, etc., can solve problems such as difficult conventional devices to measure fluid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

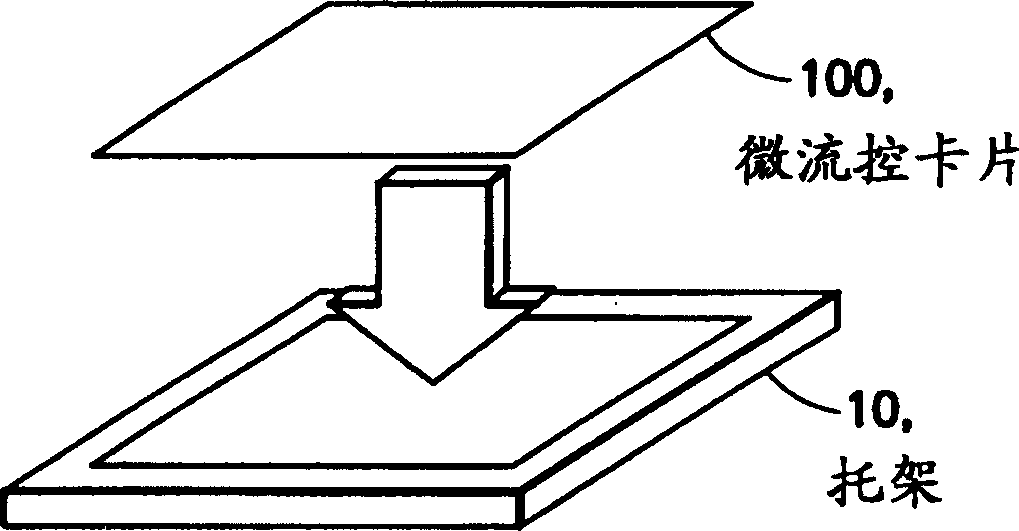

[0035] figure 1 Shows a perspective view of an embodiment of the invention with a bracket / bracket for the embodiment. Card 100 according to the present invention is a relatively thin plate comprising a matrix of fluid containers containing a set of samples to be tested. The overall dimensions of the card 100 and the positions of the modules in the matrix are in compliance with industry standards.

[0036] The card 100 fits into its location in a tray 10 having vacuum and pressure for fluid control and suitable for an automated material handling apparatus.

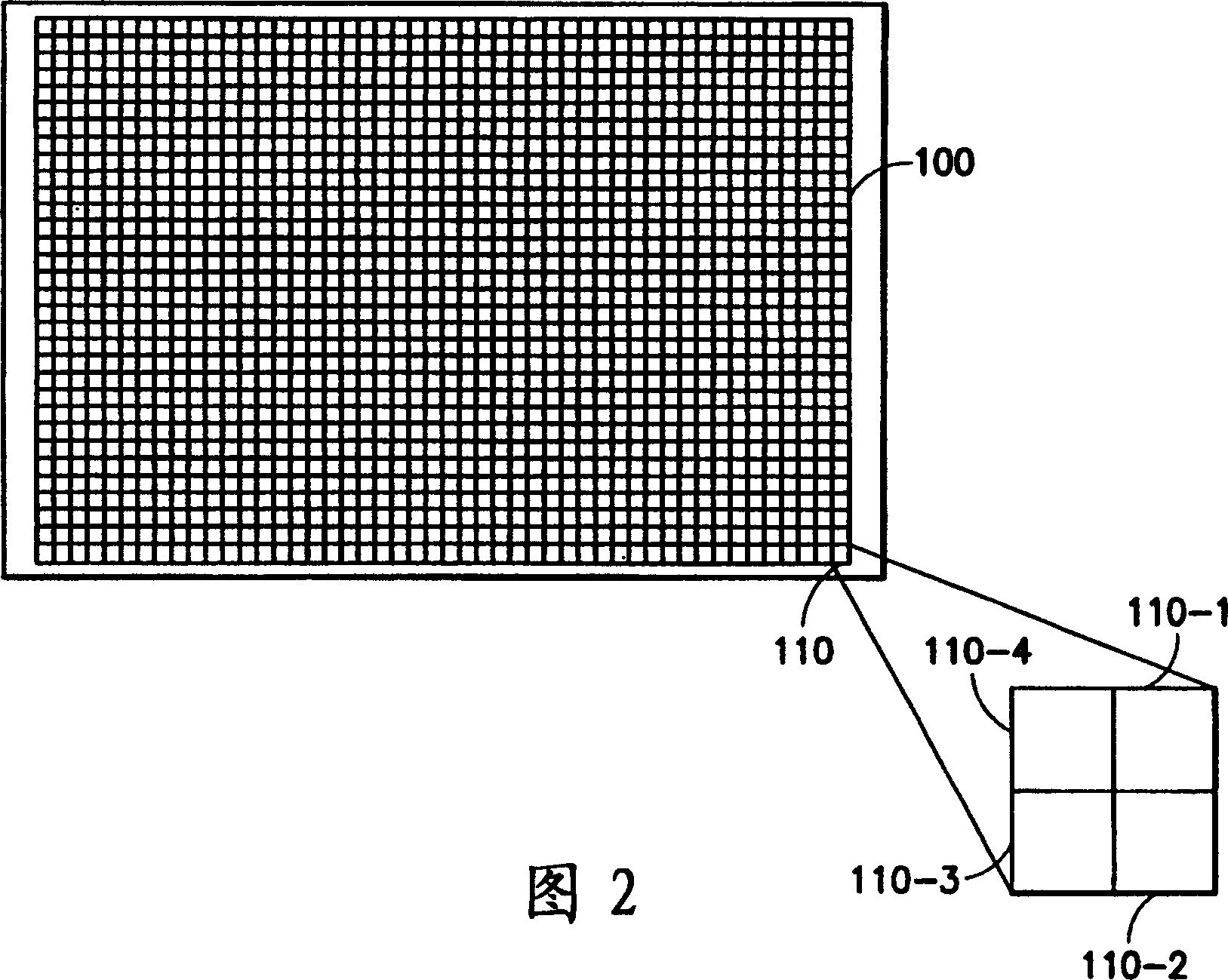

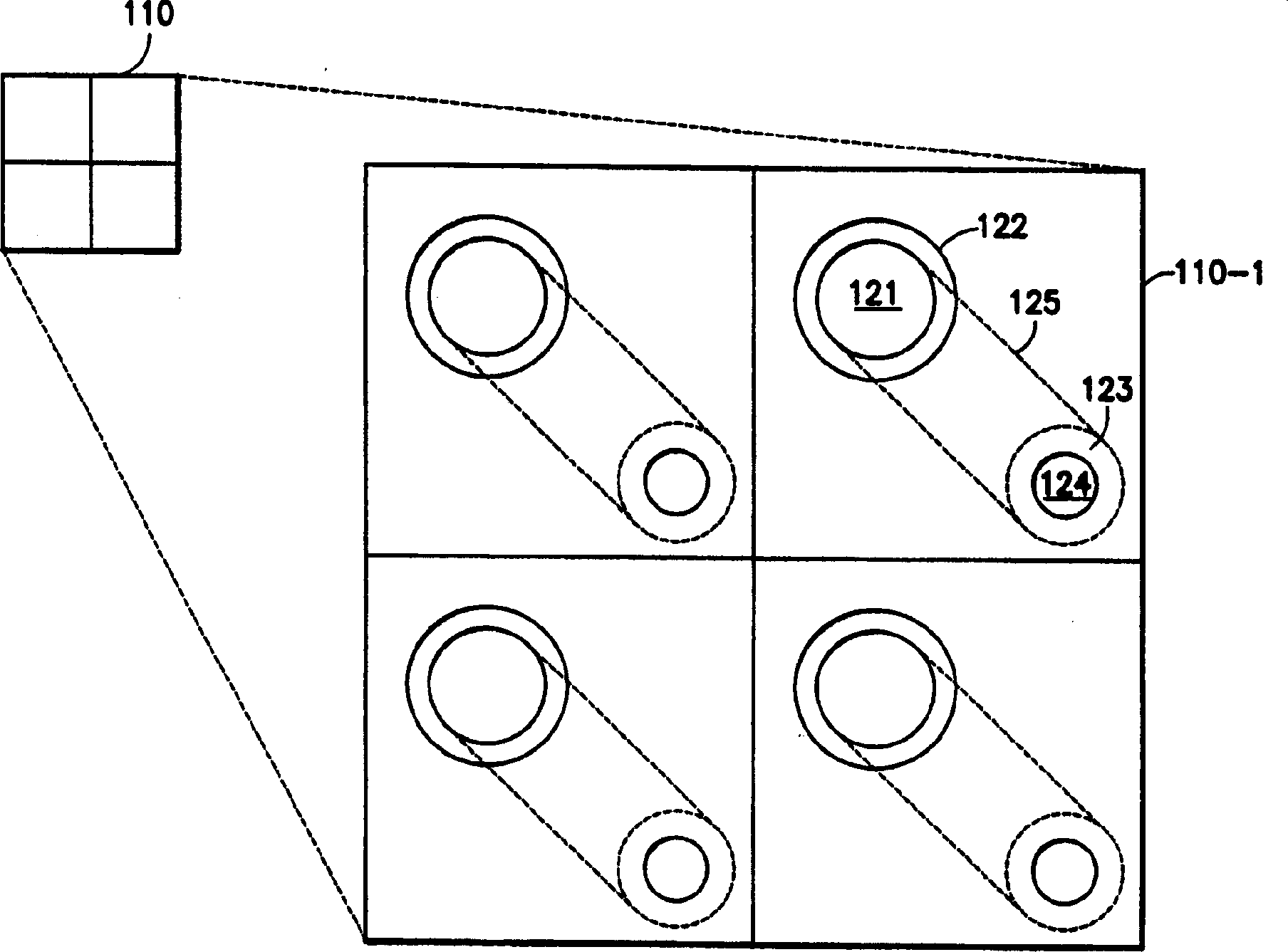

[0037] FIG. 2 shows a top view of a matrix 100 according to the invention. The industry already has established standard matrix specifications, although non-standard matrices can be used if preferred. In this case, the matrix is a group of 48×32 sub-modules, each sub-module includes a 2×2 sub-matrix composed of unit modules. On the lower right side of the figure, a sub-module 110 is shown comprising four unit modules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com