Optical waveguide module

一种光波导路、平面光波导的技术,应用在光波导光导、光导、光波导的耦合等方向,能够解决不能够正确地监视信号光光强度等问题,达到构成和制造步骤简单化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

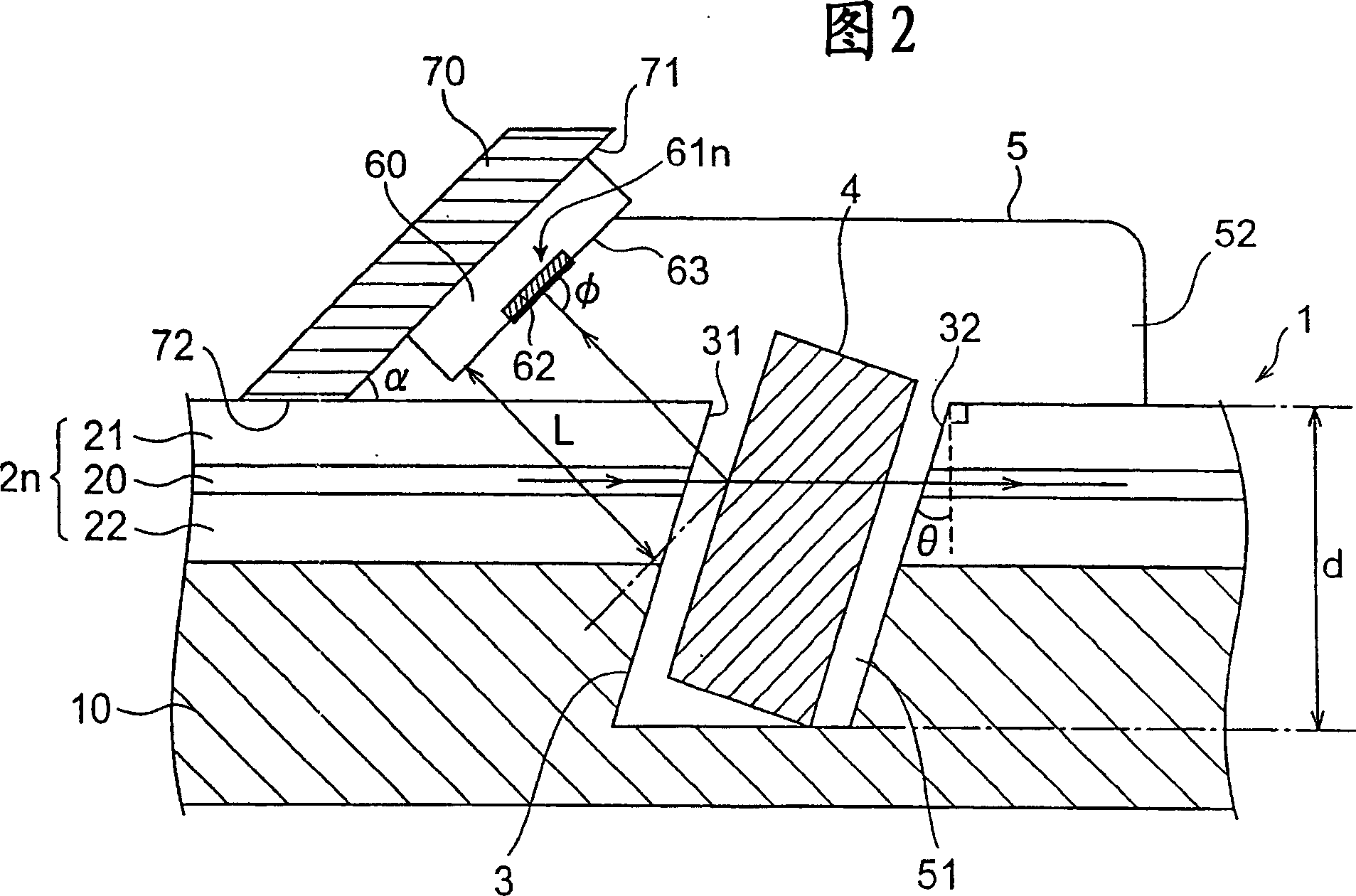

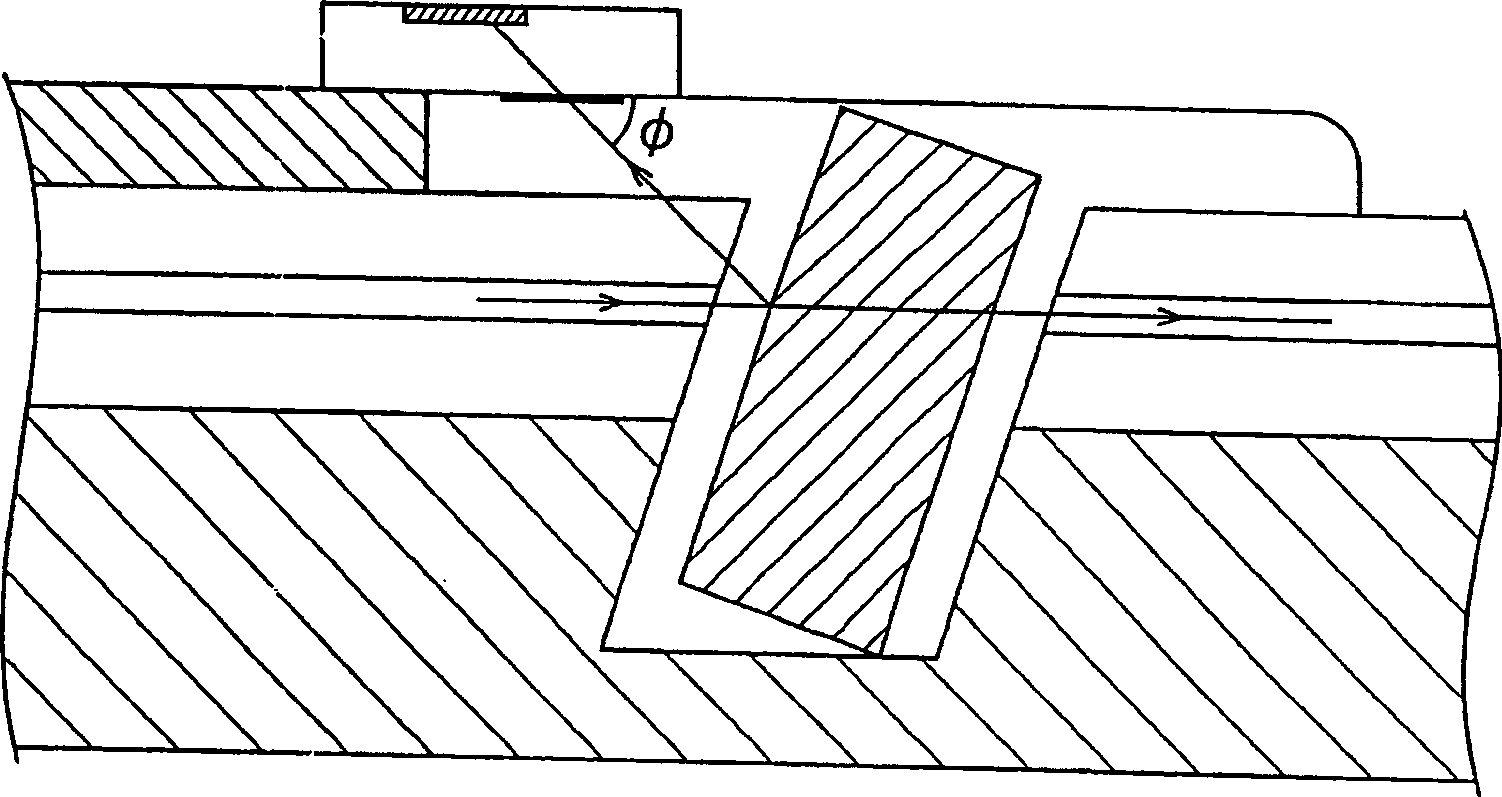

[0031] Next, we describe in detail preferred embodiments of the optical waveguide module according to the present invention together with the accompanying drawings. In addition, in the description of the drawings, the same reference numerals are attached to the same elements, and overlapping descriptions are omitted. In addition, scale ratios in the drawings do not necessarily match those in the description.

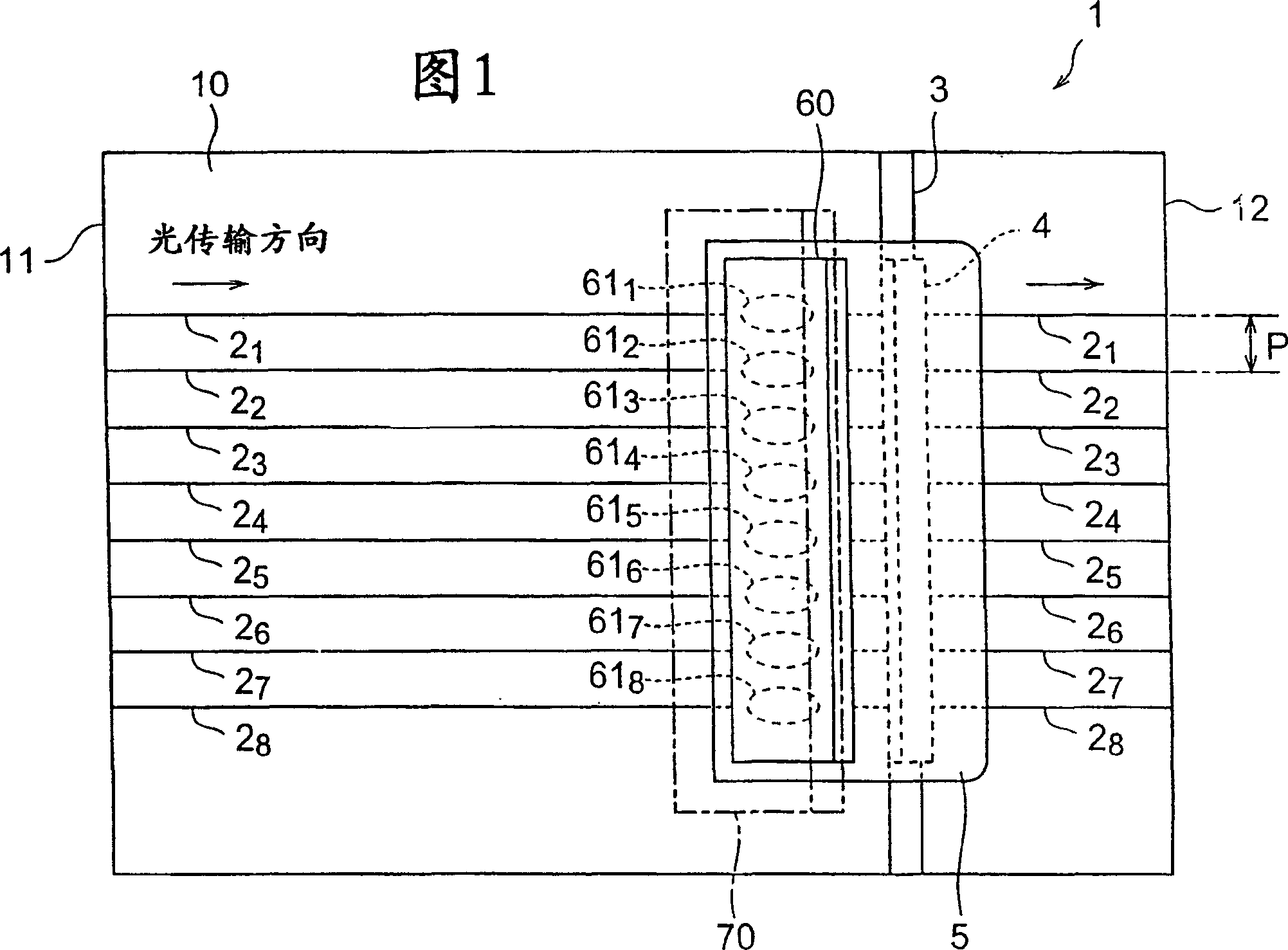

[0032] FIG. 1 is a plan view showing the configuration of a first embodiment of an optical waveguide module according to the present invention. This optical waveguide module includes a substrate 10 and eight (eight channels) optical waveguides 2 provided on the substrate 10. 1 ~2 8 Constitute the light path 1. In this embodiment, as the optical waveguide 2 1 ~2 8 , a planar waveguide type optical waveguide formed on the substrate 10 can be used.

[0033] Along the predetermined optical transmission direction (arrow direction in FIG. 1 ), from the input end 11 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com