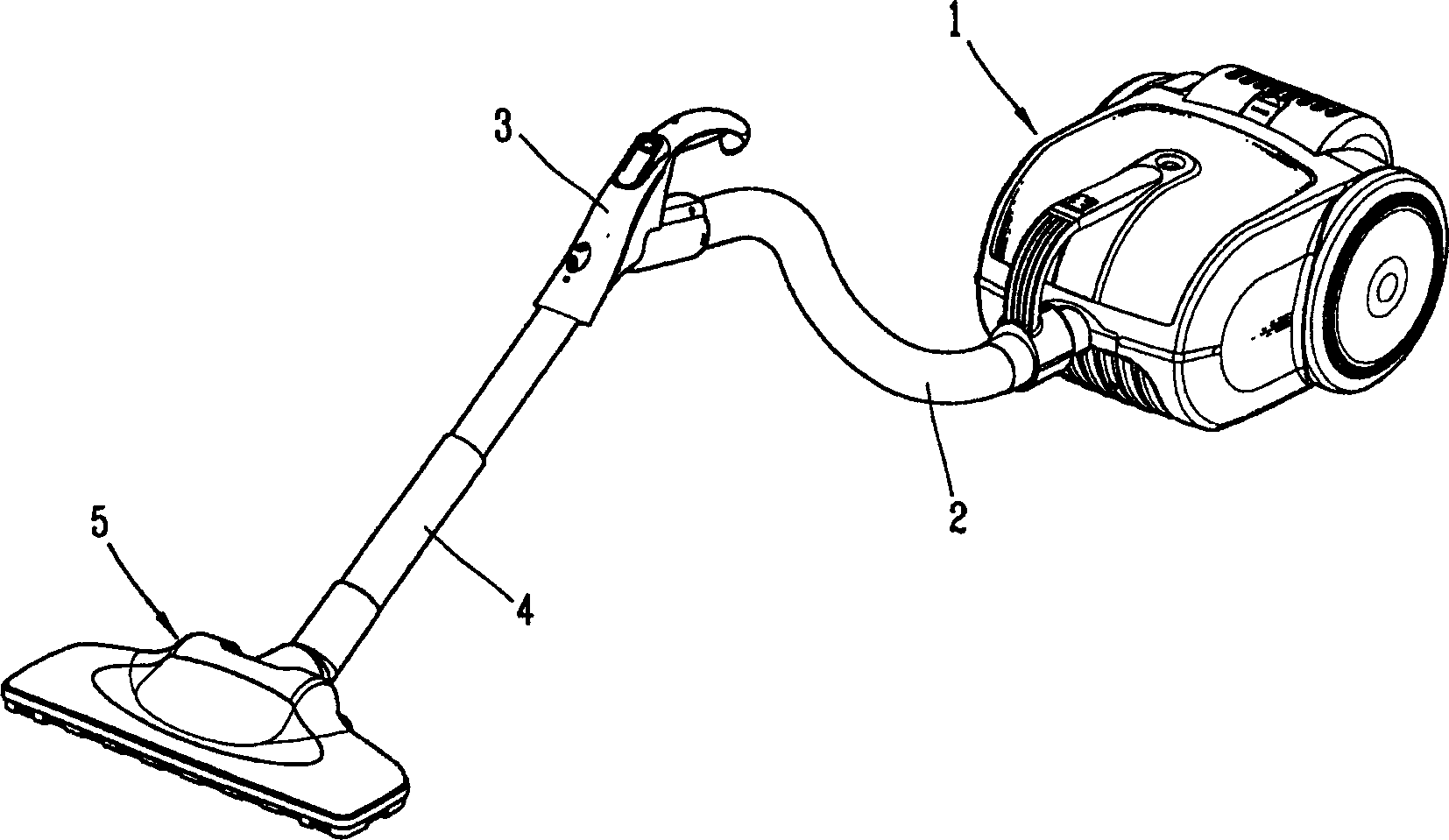

Suction nozzle structure for vacuum cleaner

A vacuum cleaner and suction port technology, applied in the direction of the suction nozzle, etc., can solve the problems of reduced cleaning efficiency, small absorption area, and reduced cleanliness, and achieve the effects of increasing the suction area, improving performance, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the nozzle structure of the vacuum cleaner of the present invention will be described in detail with reference to the drawings and embodiments.

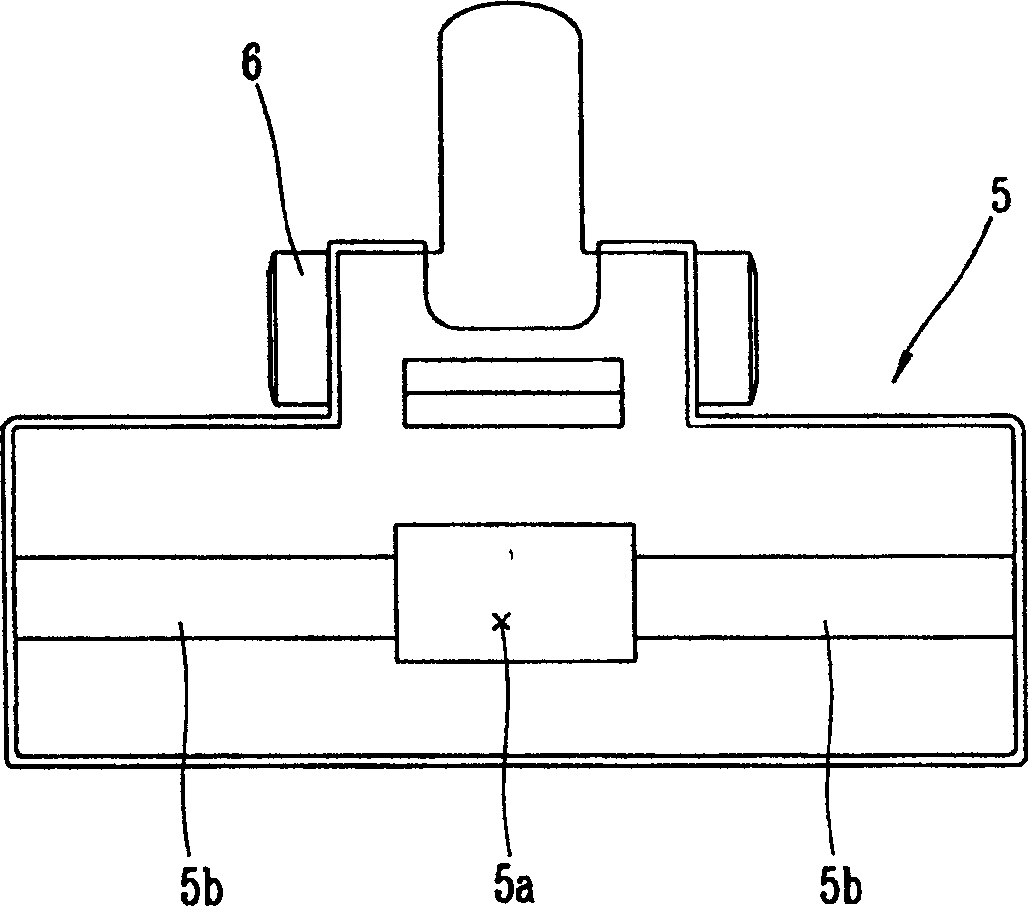

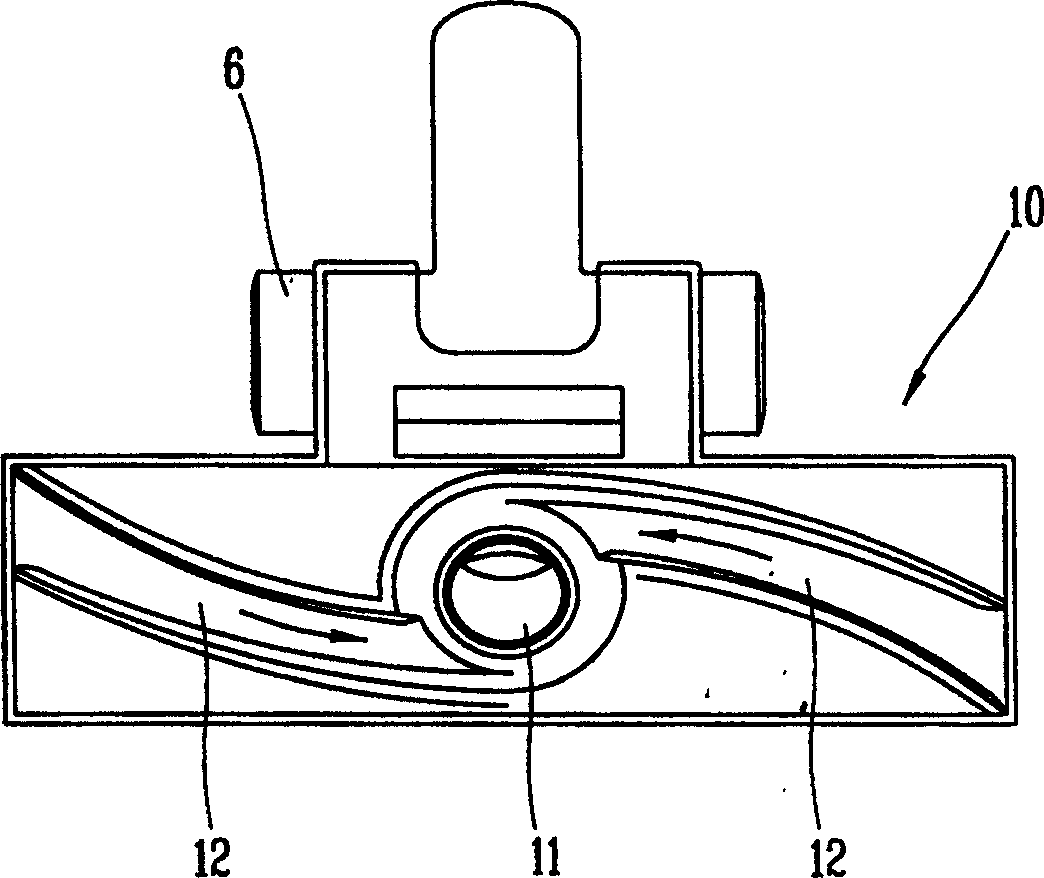

[0026] Figure 3 to Figure 9 It is a bottom view of exemplary examples of the vacuum cleaner nozzle designed in the present invention, Picture 10 It is a bottom view of another embodiment of the vacuum cleaner nozzle designed in the present invention, Picture 11 It is a longitudinal section view of another embodiment of the suction nozzle of the vacuum cleaner designed in the present invention.

[0027] As shown in the figure, the suction nozzle 10 of the vacuum cleaner designed in the present invention includes: set at the center of its bottom surface, such as figure 1 As shown, the suction port 11 communicated with the main body 1 through the extension pipe and the suction hose 2 is constituted by suction passages 12, 12 which are recessed to a certain depth on the bottom surface of the suction nozzle 10 and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com