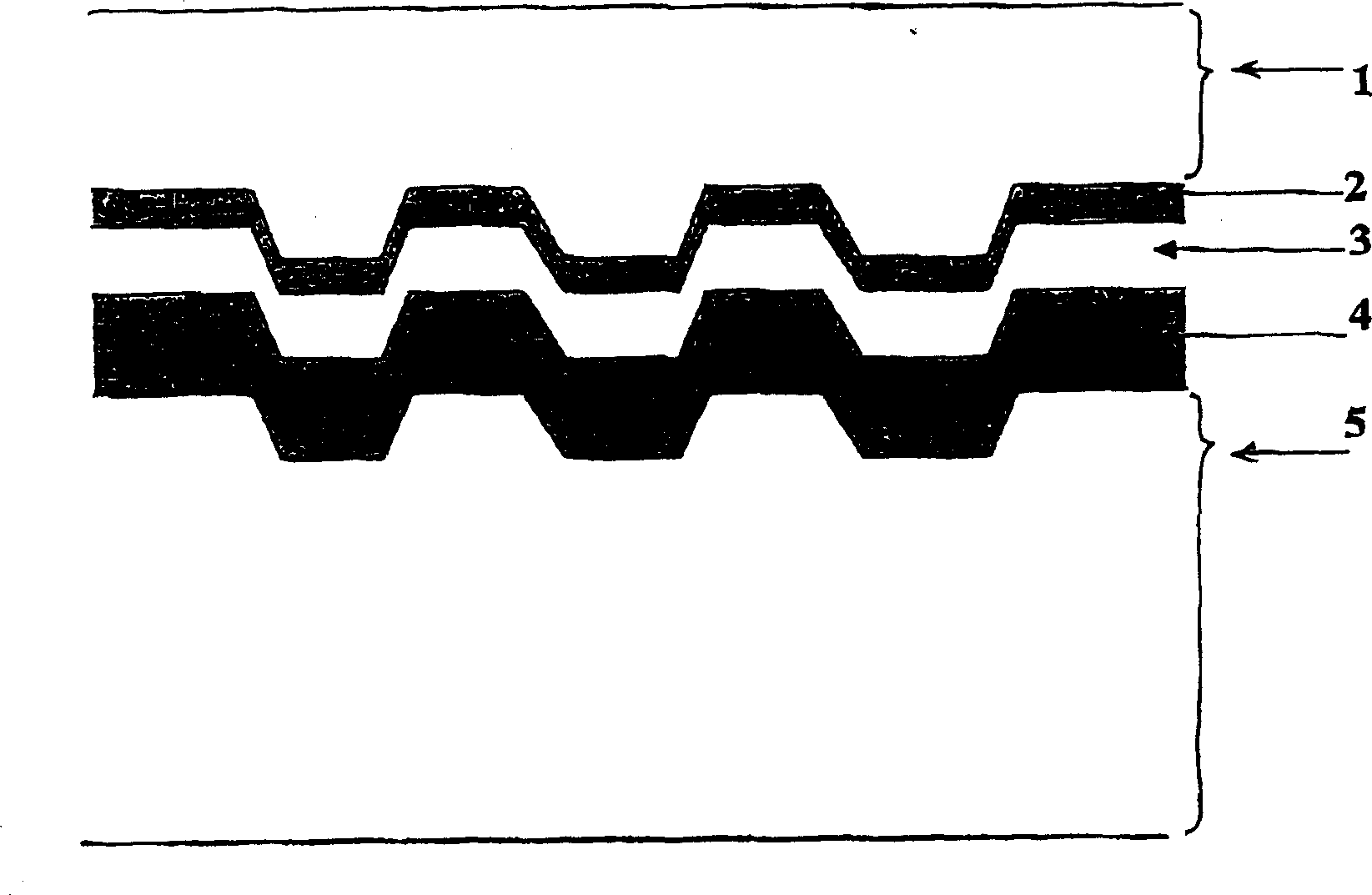

Aluminum-alloy reflective film for optical information recording and target material and recording medium for its formation

一种记录介质、铝合金的技术,应用在光学记录载体、用光学方法记录/重现、磁性记录等方向,能够解决导热率低、耐腐蚀性低、导热率高等问题,达到低导热率、低熔化温度、高耐腐蚀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0057] Al-Nd (aluminum alloy containing Nd) film and Al-Y (aluminum alloy containing Y) film were made, and the addition amount (content) of Nd and Y and the melting temperature, thermal conductivity, reflectivity and BCA of the film were studied. Burst Cutting Area) characteristics.

[0058] The above-mentioned film was produced as follows. That is, an Al-Nd thin film or an Al-Y thin film was formed (formed into a film) on a glass substrate (Corning #1737, substrate size: diameter 50 mm, thickness 1 mm) by DC magnetron sputtering. At this time, the film forming conditions are: substrate temperature: 22°C, argon pressure: 2mTorr, film forming speed: 2nm / sec, back pressure: -6 Torr. As the sputtering target, an aluminum alloy sputtering target having the same composition as that of the aluminum alloy thin film to be obtained was used.

[0059] The melting temperature of the film was measured as follows. An aluminum alloy thin film (Al-Nd thin film, Al-Y thin film) formed int...

example 2

[0068] Manufactured Al-4.0Nd-(Ta, Cr, Ti) thin film (thin film composed of aluminum alloy containing 4.0at% Nd and at least one of Ta, Cr, Ti) and studied the addition of Ta, Cr, Ti The relationship between the amount and the melting temperature, thermal conductivity, reflectivity, corrosion resistance and BCA characteristics of the film.

[0069] The above-mentioned film was produced as follows. That is, an Al-4.0Nd-(Ta, Cr, Ti) alloy thin film was fabricated (formed into a film) on a glass substrate (Corning #1737, substrate size: 50 mm in diameter, 1 mm in thickness) by DC magnetron sputtering. At this time, the film forming conditions are: substrate temperature: 22°C, argon pressure: 2mTorr, film forming speed: 2nm / sec, back pressure: -6 Torr. As the sputtering target, an aluminum alloy sputtering target having the same composition as that of the aluminum alloy thin film to be obtained was used.

[0070] The melting temperature of the film was measured as follows. An al...

example 3

[0078] Make Al-4.0Nd-[Mo, V, W, Zr, Hf, Nb, Ni (hereinafter, all referred to as Mo~Nb, Ni)], thin film (containing 4.0at% Nd while containing Mo~Nb, Ni Films composed of more than one aluminum alloy), the relationship between the addition amount of Mo-Nb and Ni and the melting temperature, thermal conductivity, reflectivity, corrosion resistance and BCA characteristics of the film was studied.

[0079] The above-mentioned film was produced as follows. That is, an Al-4.0Nd-(Mo-Nb, Ni) alloy thin film was fabricated (formed into a film) on a glass substrate (Corning #1737, substrate size: diameter 50 mm, thickness 1 mm) by DC magnetron sputtering. At this time, the film forming conditions are: substrate temperature: 22°C, argon pressure: 2mTorr, film forming speed: 2nm / sec, back pressure: -6 Torr. As the sputtering target, an aluminum alloy sputtering target having the same composition as that of the aluminum alloy thin film to be obtained was used.

[0080] The melting temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| laser power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com