Double-sealing wash-free high-pressure stop valve

A technology of double-seal and stop valve, which is applied to the device for pressure relief on the sealing surface, lift valve, valve details and other directions, which can solve the problems affecting the service life and safe operation of the valve, increasing the specific pressure of the valve seal, etc. Achieve the effects of avoiding erosion, reliable sealing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

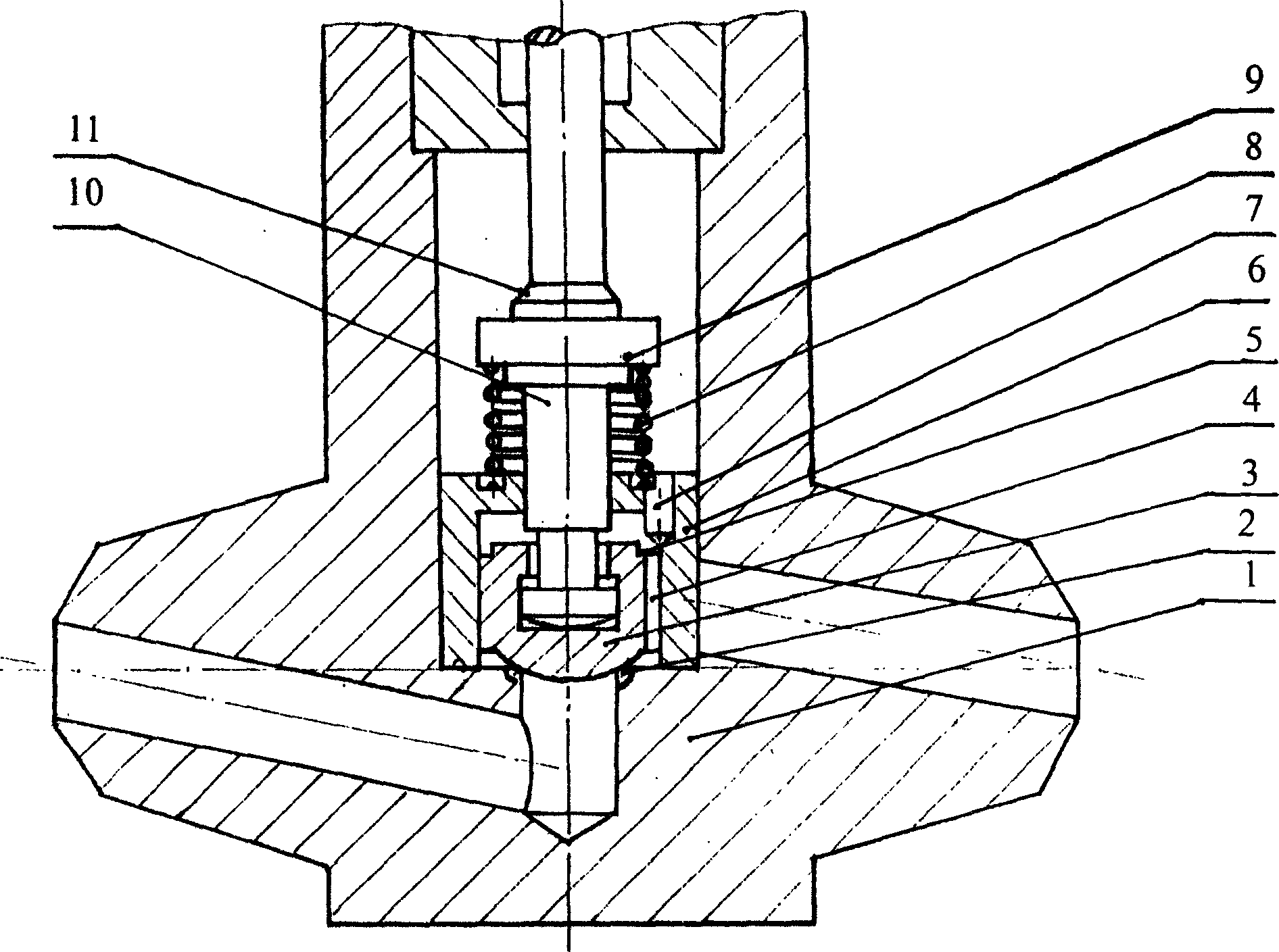

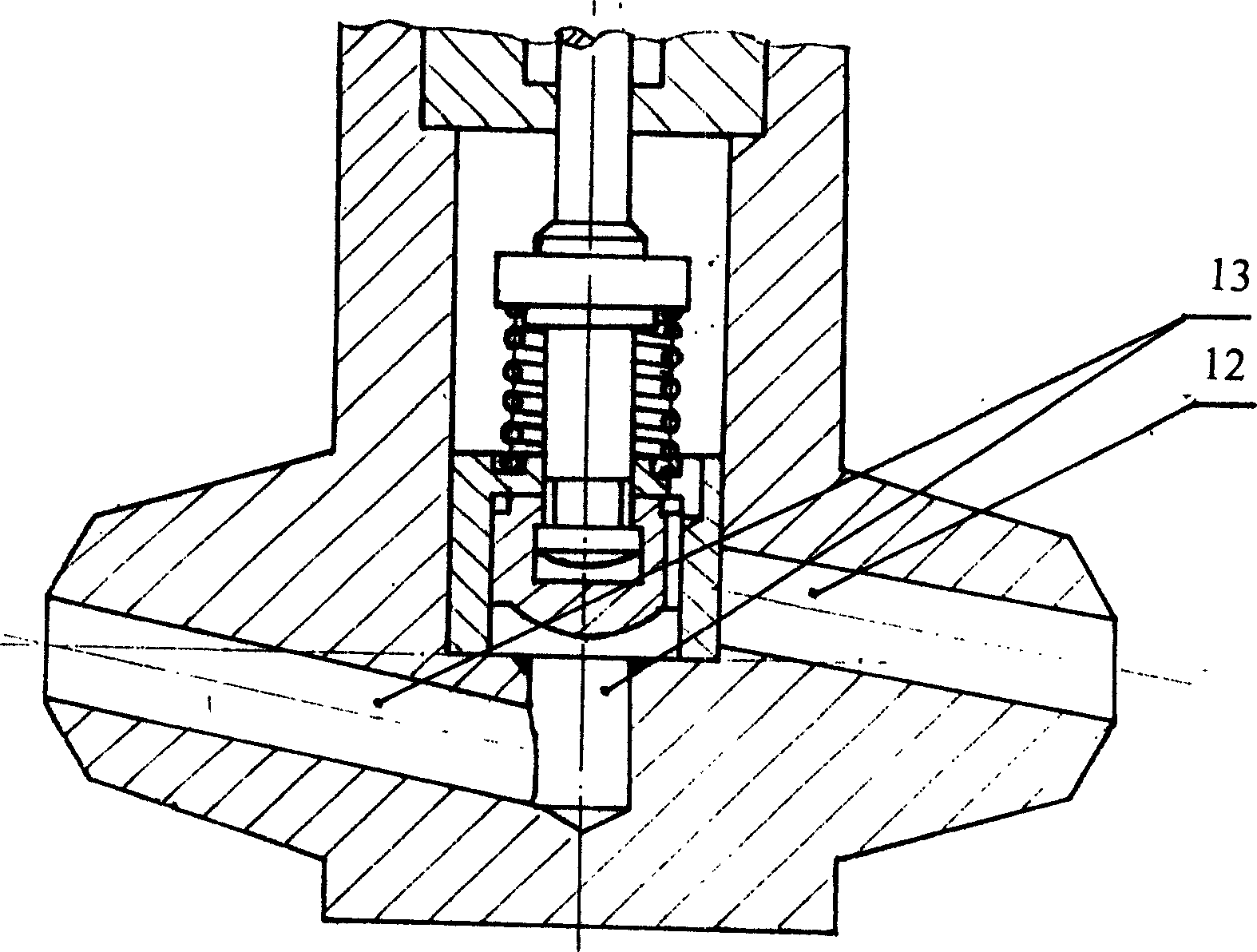

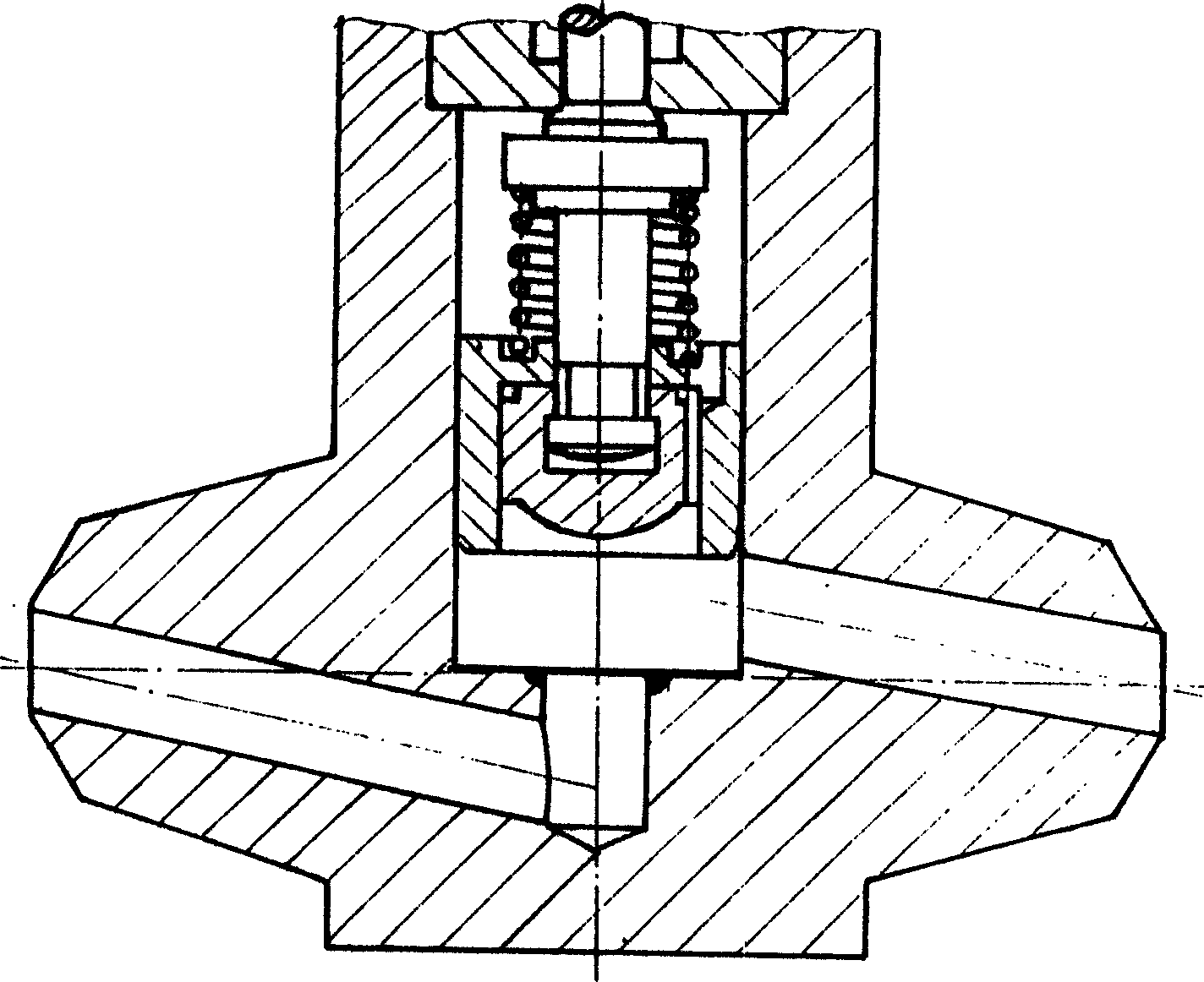

[0012] Such as Figure 1 to Figure 3 As shown, the main features of the double-sealed flush-free high-pressure stop valve of the present invention are: the sealing device that cooperates with the round hole in the inner cavity of the valve body 1 is to pass the valve stem 10 through the inner hole of the spring seat 9 and the compression spring (8) and the valve The small round hole and the big round hole of the flap shield 6 are connected to the valve flap 3 at the end, and are driven by the valve stem 10 to move up and down to achieve the opening and closing effect, and the spring seat 9 is fixed on the upper seal of the valve stem 10. 11, a compression spring 8 is installed between the upper part of the disc guard 6 and the lower part of the spring seat 9, and has a certain amount of initial pressure compression; the outer circle of the disc 3 and the large circular hole of the disc guard 6 Cooperate, its height is less than the height of the inner circle of the disc guard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com