Base plate treater, slit jet nozzle and mechanism for determining liquid filling degree and gas mixing degree in filled body

A technology of substrate processing device and processing liquid, which is applied in the directions of spraying device, spraying device, and device for coating liquid on the surface, etc., can solve the problems of relative air mixing, etc., and achieve the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] (first embodiment)

[0075] (overall composition)

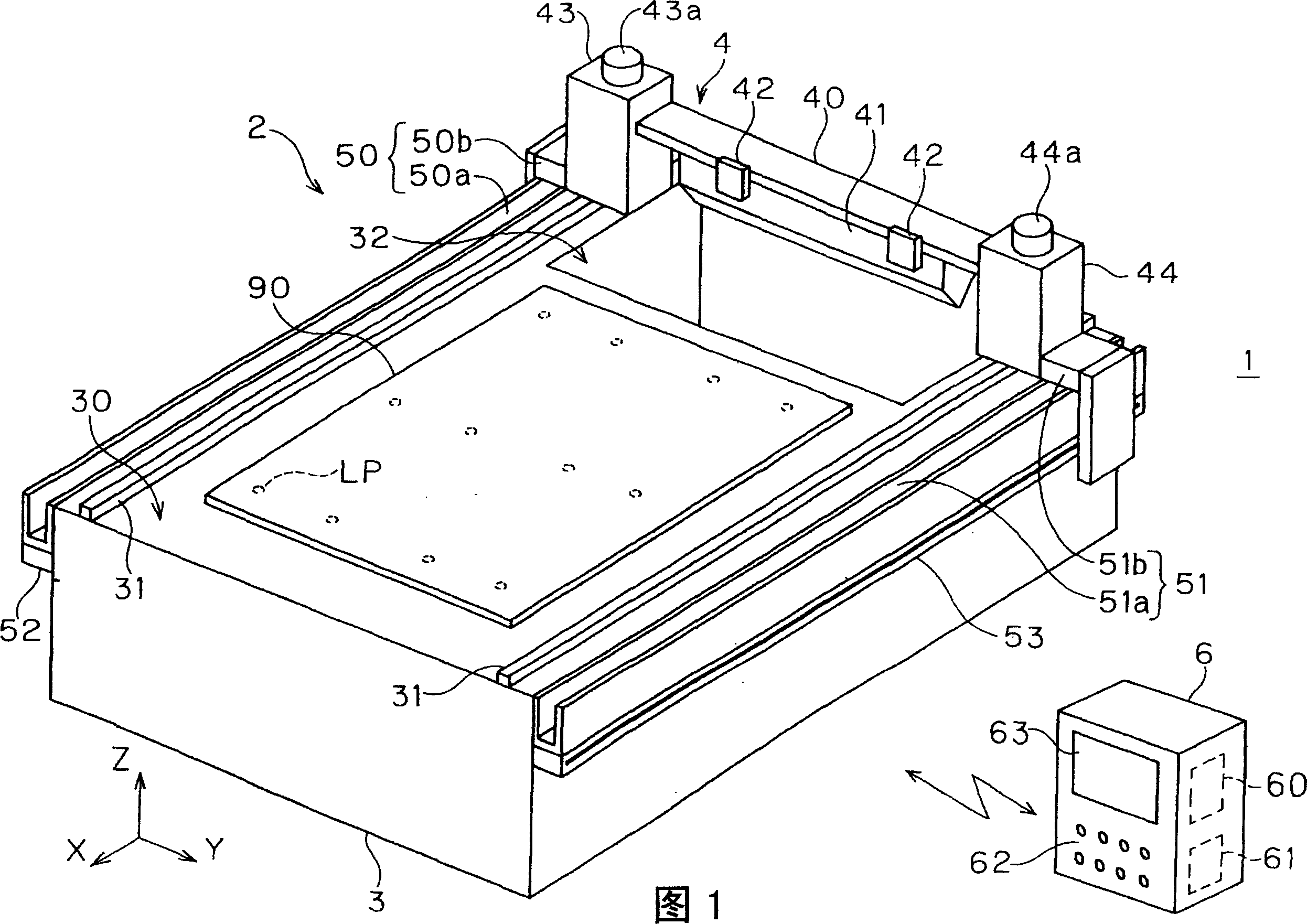

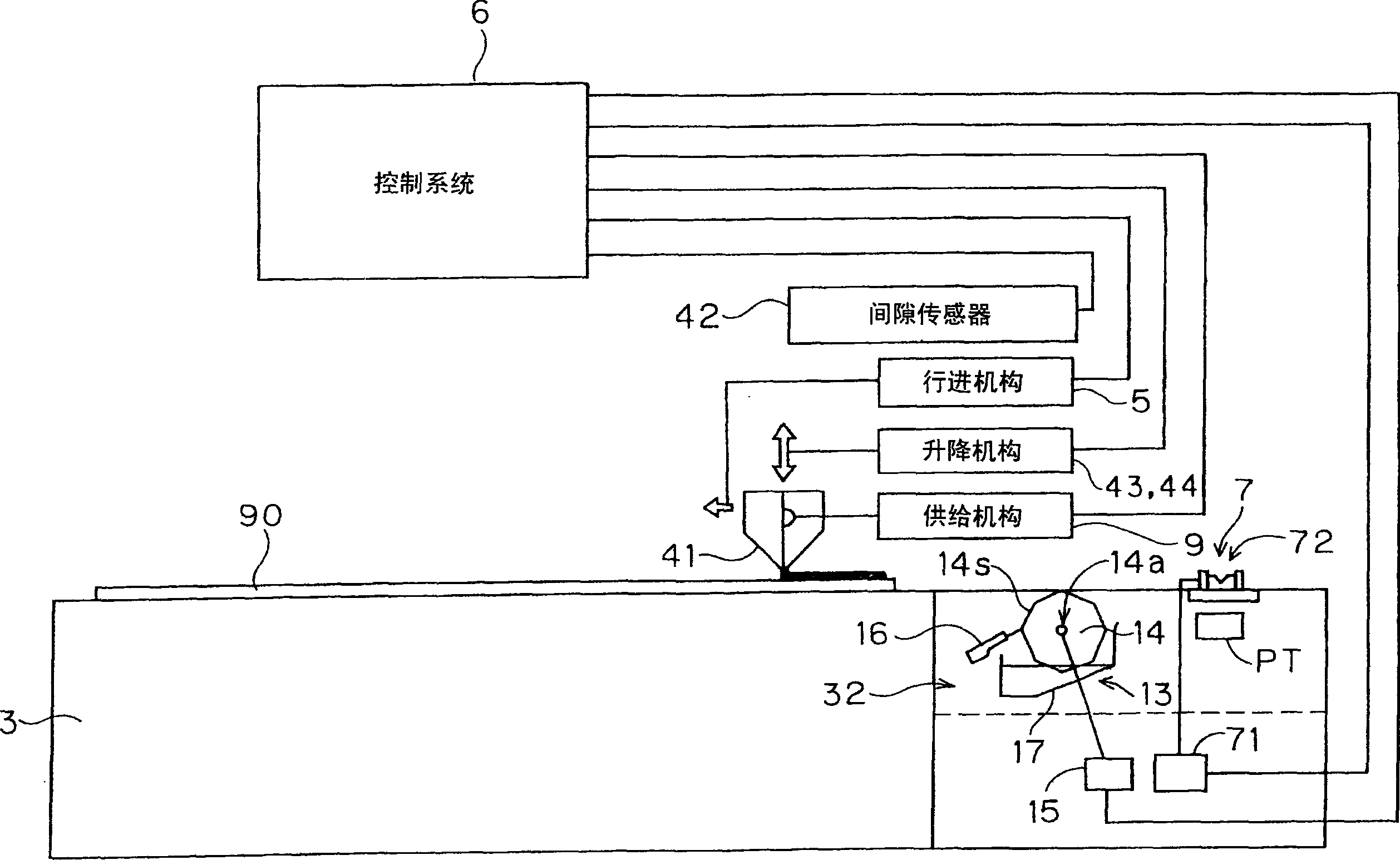

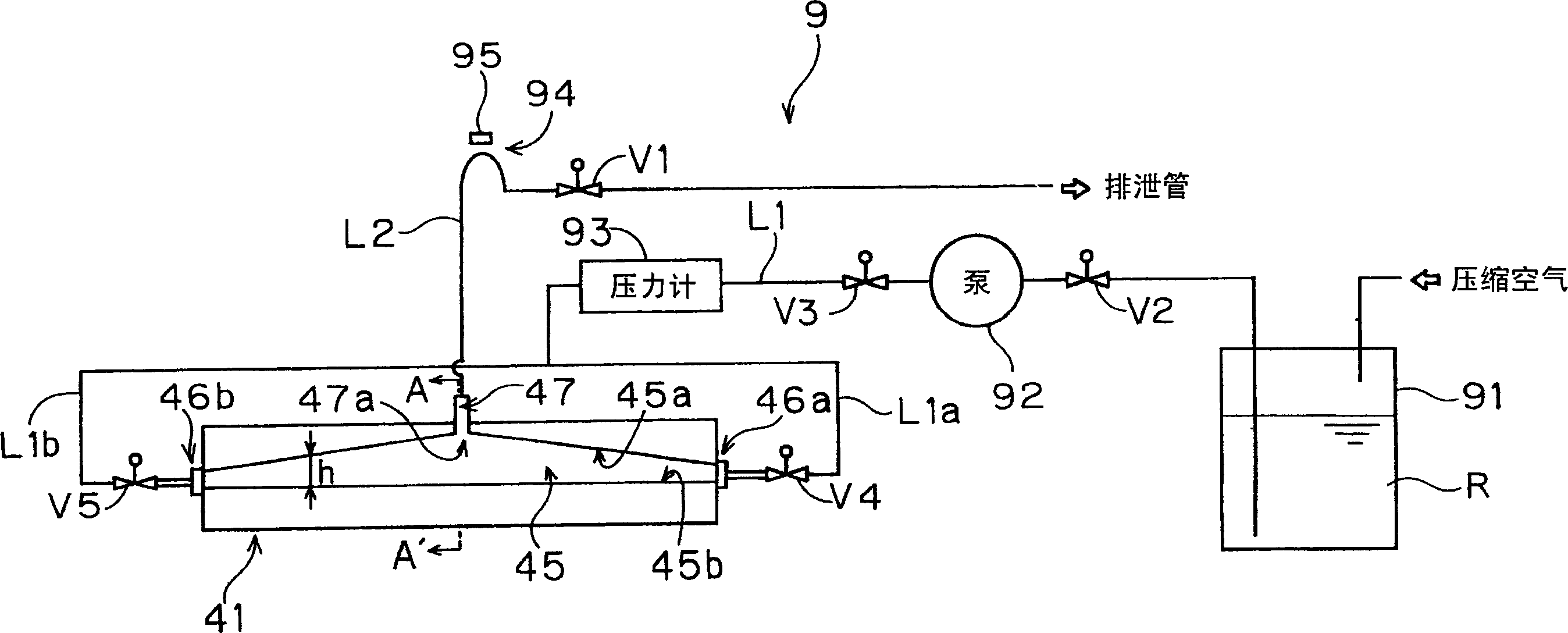

[0076] FIG. 1 is a perspective view showing a substrate processing apparatus 1 according to a first embodiment of the present invention. figure 2 It is a view showing main components of a resist liquid coating operation while showing a side cross section of the main body 2 of the substrate processing apparatus 1 .

[0077] The substrate processing apparatus 1 is roughly divided into a main body 2 and a control system 6. A square glass substrate used for manufacturing a screen panel of a liquid crystal display device is used as a substrate to be processed (hereinafter simply referred to as a "substrate") 90, and is formed on the substrate by selective etching. In the process of forming the electrode layer on the surface of the substrate 90, etc., it is configured as a coating processing apparatus for coating a resist liquid as a processing liquid on the surface of the substrate 90. Therefore, in this embodiment, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com