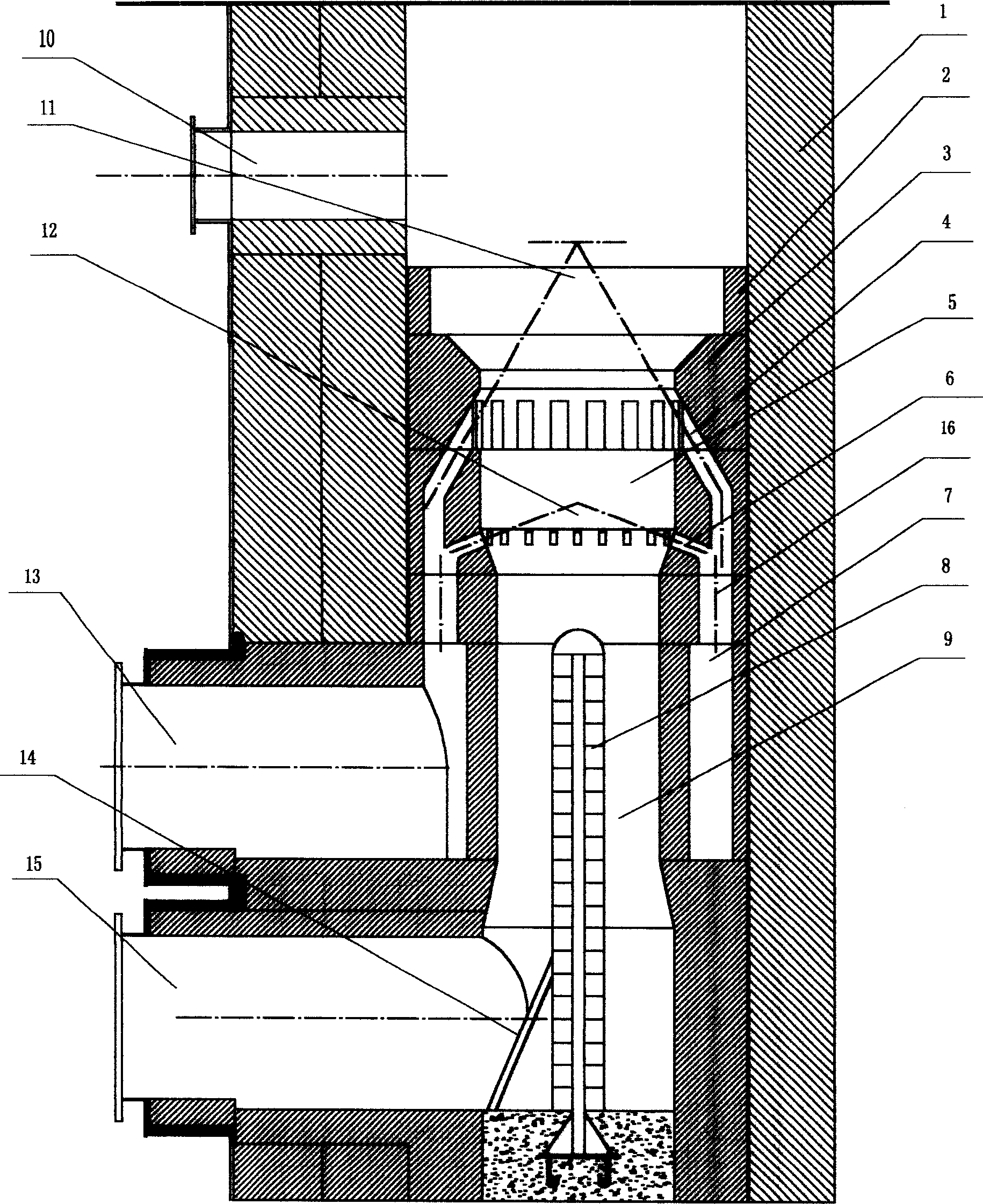

Blast furnace hot blast stove ceramic burner with central circumferential flow column

A ceramic burner and burner technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as reducing the use effect and life of the burner, uneven heating of the lining of the fire, and reducing the theoretical combustion temperature of the fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

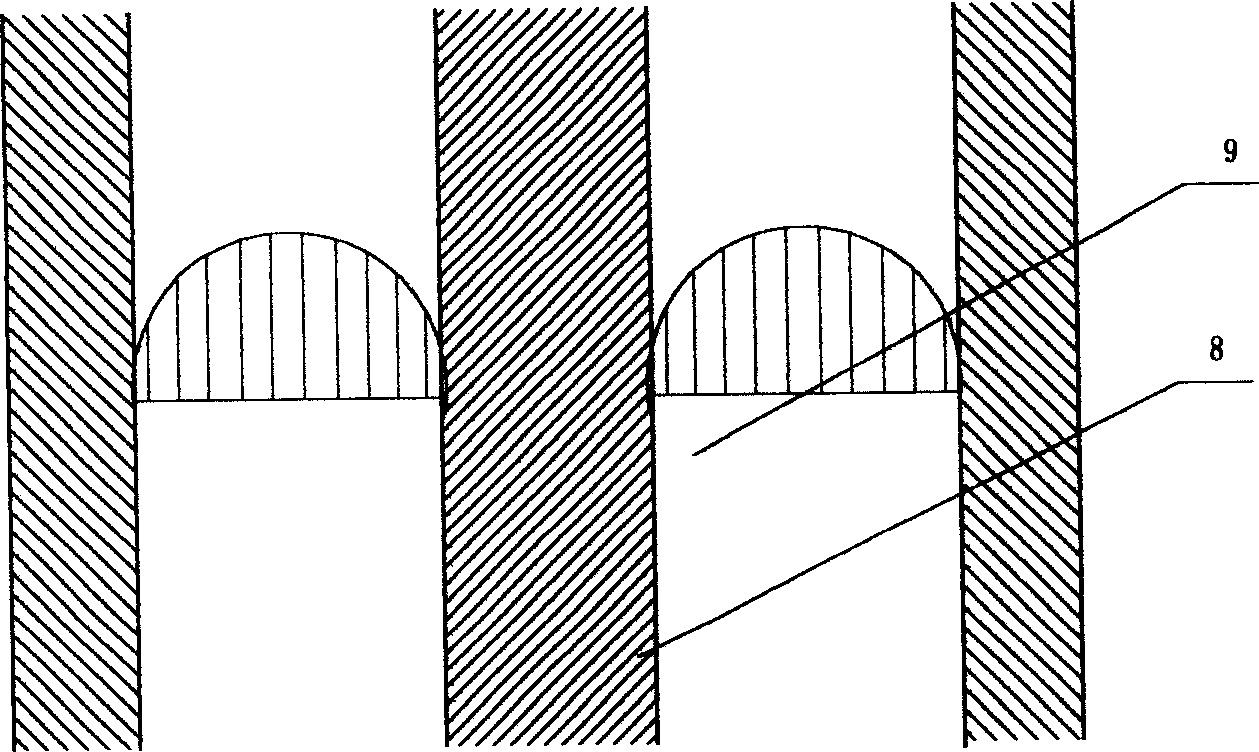

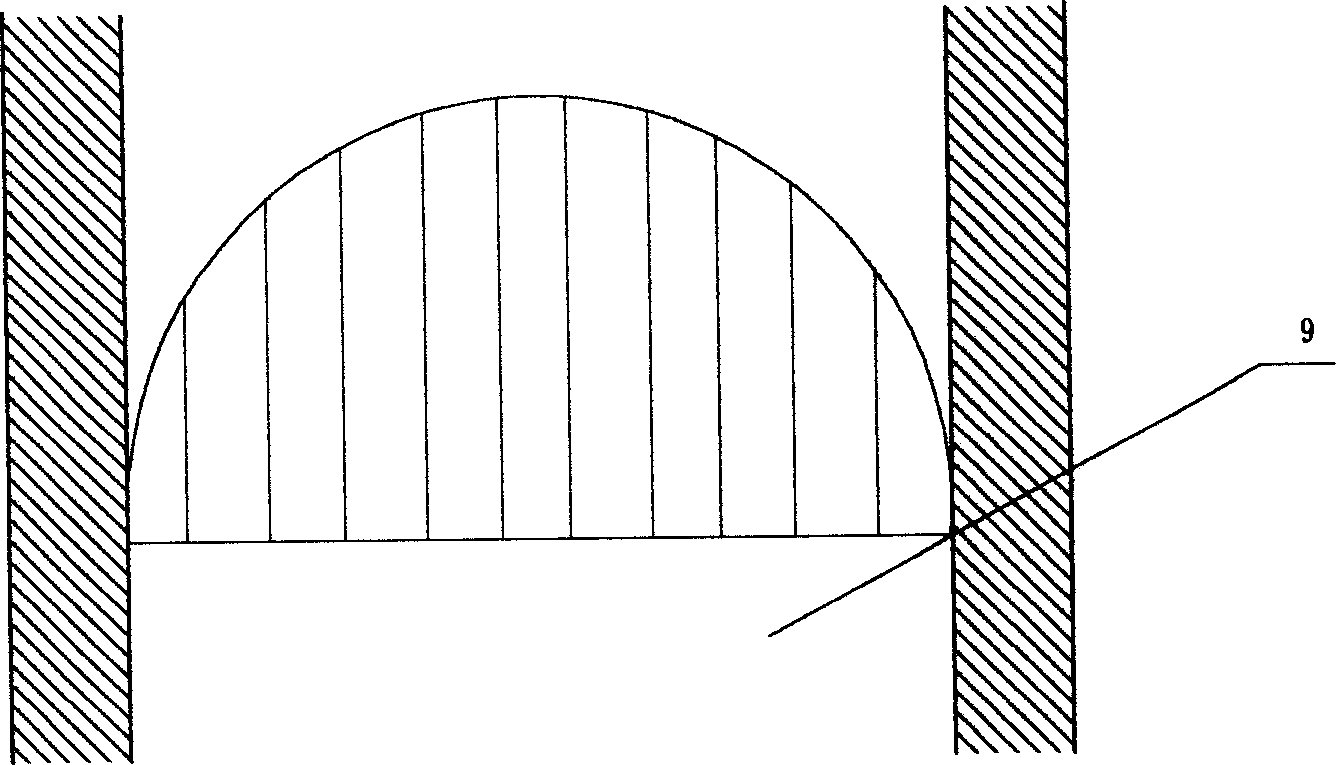

[0016] The most characteristic parts of the present invention will be further described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings, the gas passage 9 of the burner of the present invention is arranged in the center of the burner, the air passage 7 surrounds the outside of the gas passage, and the center of the gas passage is provided with a central winding column 8, which runs through the central winding column 8. Gas channel, its height does not exceed the height of protective cap 3. Directly facing the gas inlet 15 around the column is provided with a gas deflector 14, the horizontal angle of which is 0-80°, and the shape of the deflector surface of the deflector is a plane, an arc or a curved surface. The ceramic burner is equipped with a gas center surrounding flow column and a gas guide plate, which eliminates the eddy current loss of the gas inlet, reasonably organizes the gas flow in the channel, and reduces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com