Two-wire system multiple sensors liquid level transmitting instrument

A liquid level transmitter and multi-sensor technology, which is applied in the direction of displaying liquid level indicators through pressure measurement, can solve the problems of affecting the sealing effect, limiting the locking force, and inaccurate measurement, so as to achieve reliable sealing and improve sealing performance , Increase the effect of locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

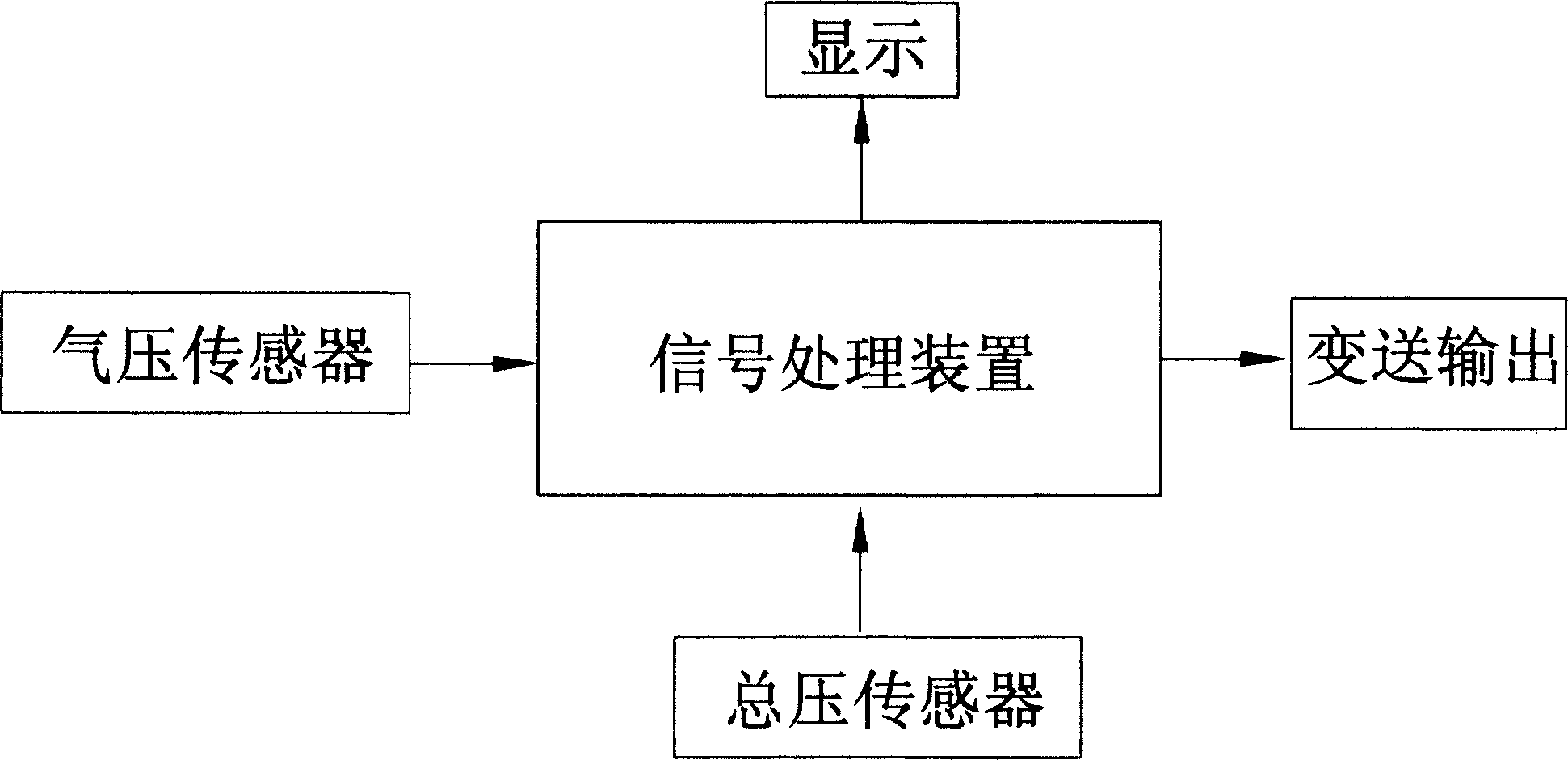

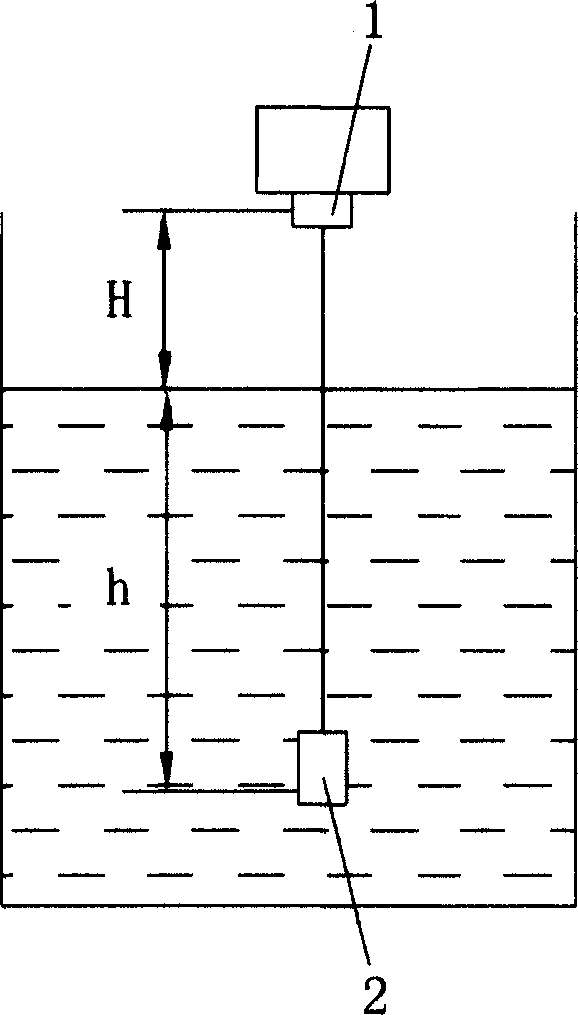

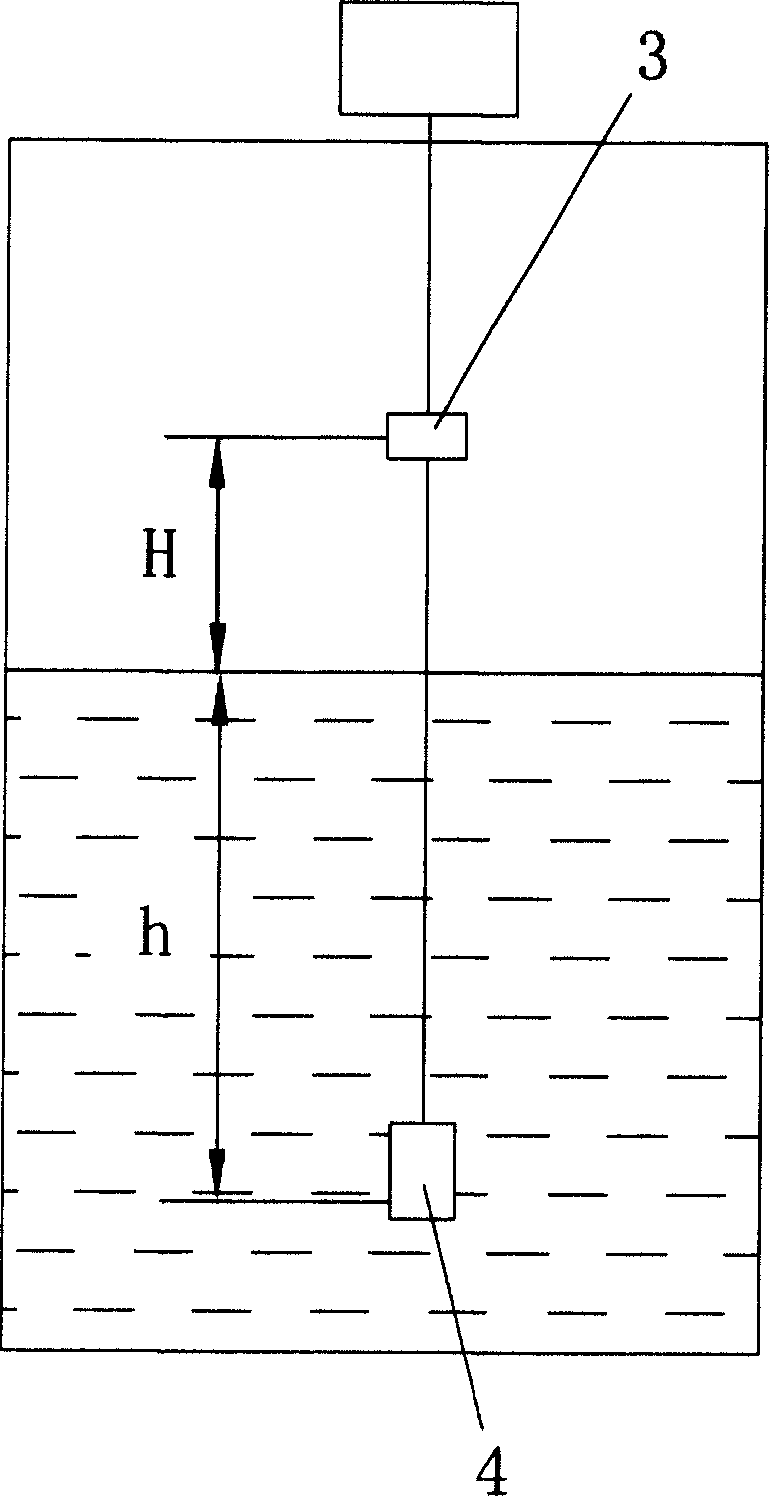

[0065] Such as figure 1 As shown, the present invention uses two absolute pressure sensors to measure the pressure value in the liquid medium and the atmospheric pressure value above the liquid surface respectively when measuring the liquid level, and one is set at the position above the liquid surface for actively measuring the atmospheric pressure value above the liquid surface An absolute pressure sensor, and another absolute pressure sensor for measuring the total pressure below the liquid surface is installed at the measured point, that is, the sum of the pressure above the liquid surface plus the liquid pressure, and the signal processing device measures the total pressure through two absolute pressure sensors. After obtaining the atmospheric pressure above the liquid surface and the total pressure below the liquid surface, calculate the difference ΔP between the total pressure and the atmospheric pressure above the liquid surface, that is, the hydraulic pressure value, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com