Apparatus of humidifying and distributing lime powder for dry process desulfurizing equipment

A dry desulfurization and distribution device technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of dust pollution and uneven distribution, and achieve uniform distribution, smooth material in and out, and good humidification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

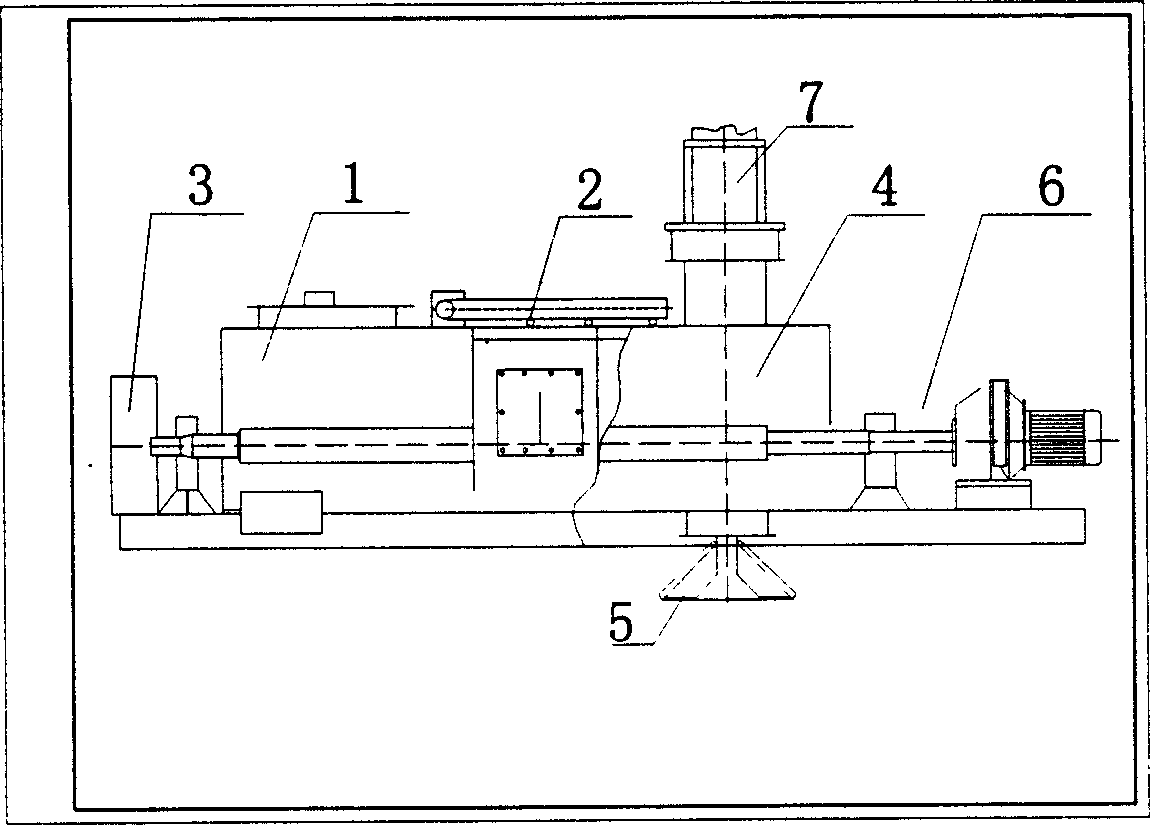

[0008] The device mainly includes two main parts of humidification and discharge. The humidification chamber 1 is equipped with a water inlet pipeline, and the material enters from the feed port 3. Driven by the horizontal motor unit, it first passes through the humidification chamber to rotate and humidify, and then enters the discharge chamber 4, and automatically falls into the conical disk under the action of gravity. 5, the conical disc body is driven by the longitudinal motor unit 7, and there are also holes for cloth on the conical disc body. Under the joint action of gravity and centrifugal force, the material is evenly dispersed when falling to achieve uniform cloth distribution. The speed of the conical disc turntable can be 5-3000 rpm, and the feeding amount is determined according to different speeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com