Pumped liquid cooling system using a phase change refrigerant

A cooling system and refrigerant pump technology, applied in refrigeration and liquefaction, refrigerators, cooling/ventilation/heating renovation, etc., can solve problems such as damage to compressors, shorten compressor life, etc., and achieve lower temperature drop and lower additional power. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

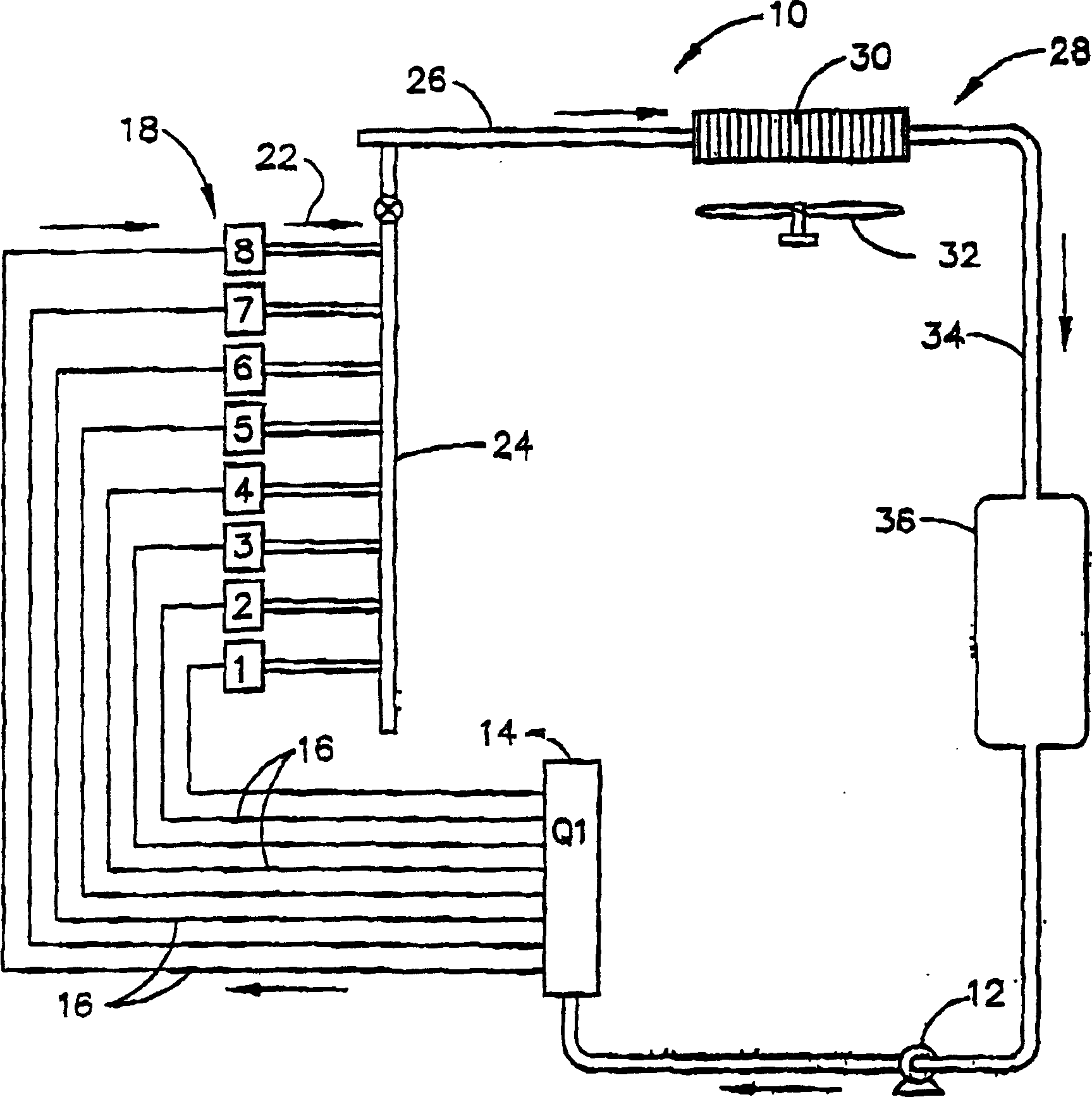

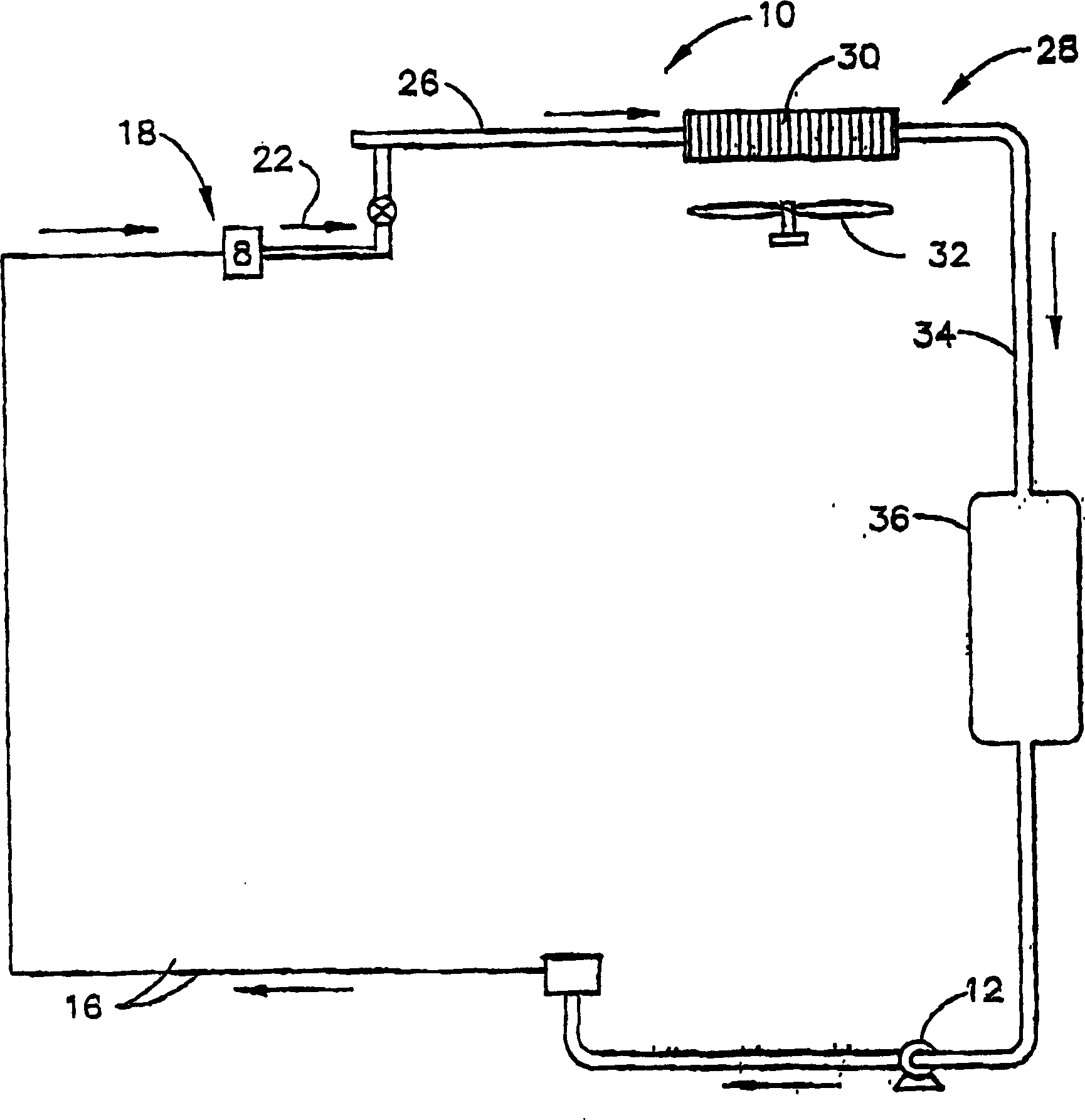

[0017] now refer to Figure 1A and Figure 1B , shows a cooling system 10 that circulates a refrigerant as a working fluid. The refrigerant can be any suitable evaporable refrigerant, such as R-134a. The cooling cycle may start at liquid pump 12 shown as a sealed liquid pump. A pump 12 pumps the liquid refrigerant to a liquid manifold 14 where the liquid refrigerant is distributed to one or more branches or lines 16 . Each branch or line 16 supplies liquid refrigerant from a manifold 14 to a cooling stage 18 . The condensation temperature of the refrigerant is preferably controlled to be higher than the dew point of the surroundings where the cooling stage evaporator unit is located.

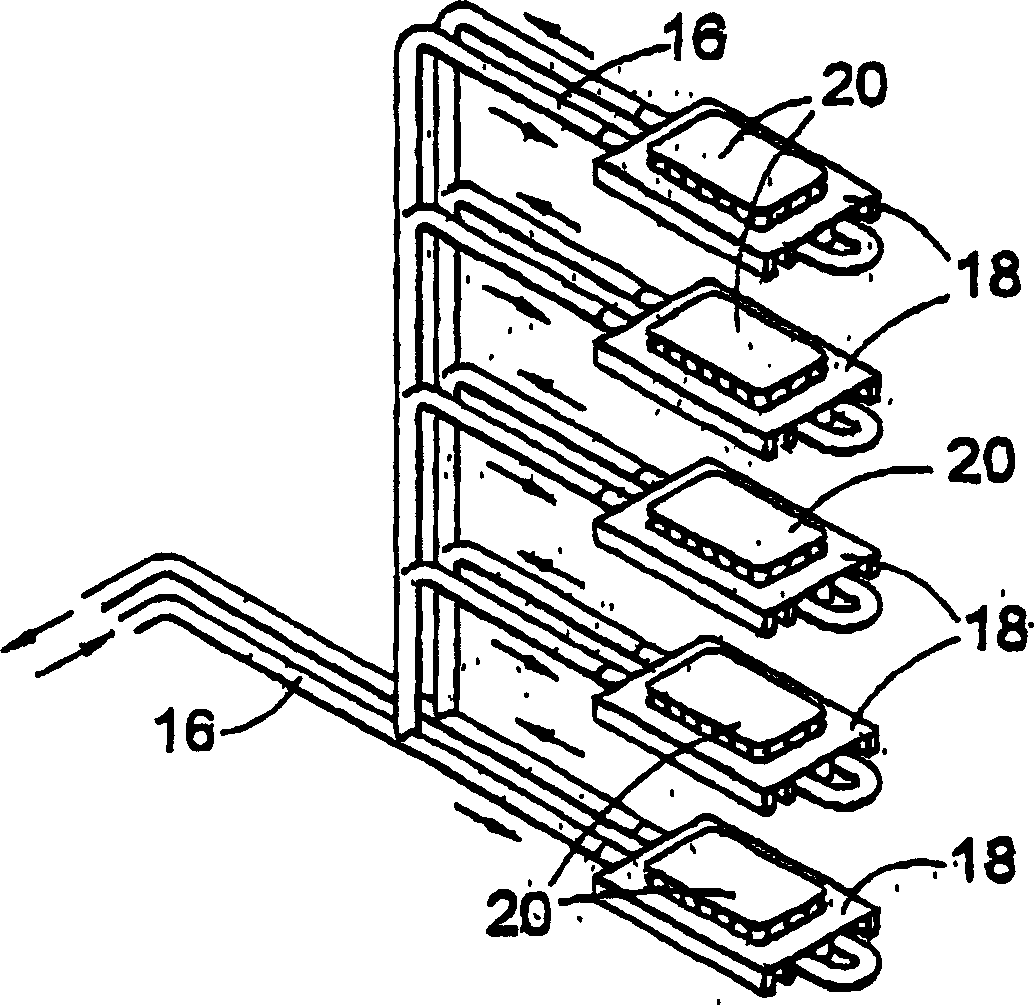

[0018] Such as figure 2 As shown, each cooling stage 18 is in thermal contact with an electrical or electronic component 20 to be cooled such that liquid refrigerant evaporates at system pressure. Depending on how much heat is generated by element 20 , none, some, or all of the liquid refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com