Ejecting and compensating mechanism of disk brake having brake for parking

A disc brake and compensation mechanism technology, applied in the direction of brakes, brake components, brake types, etc., can solve the problems of large volume of the brake device, affecting the sealing effect, and difficult manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

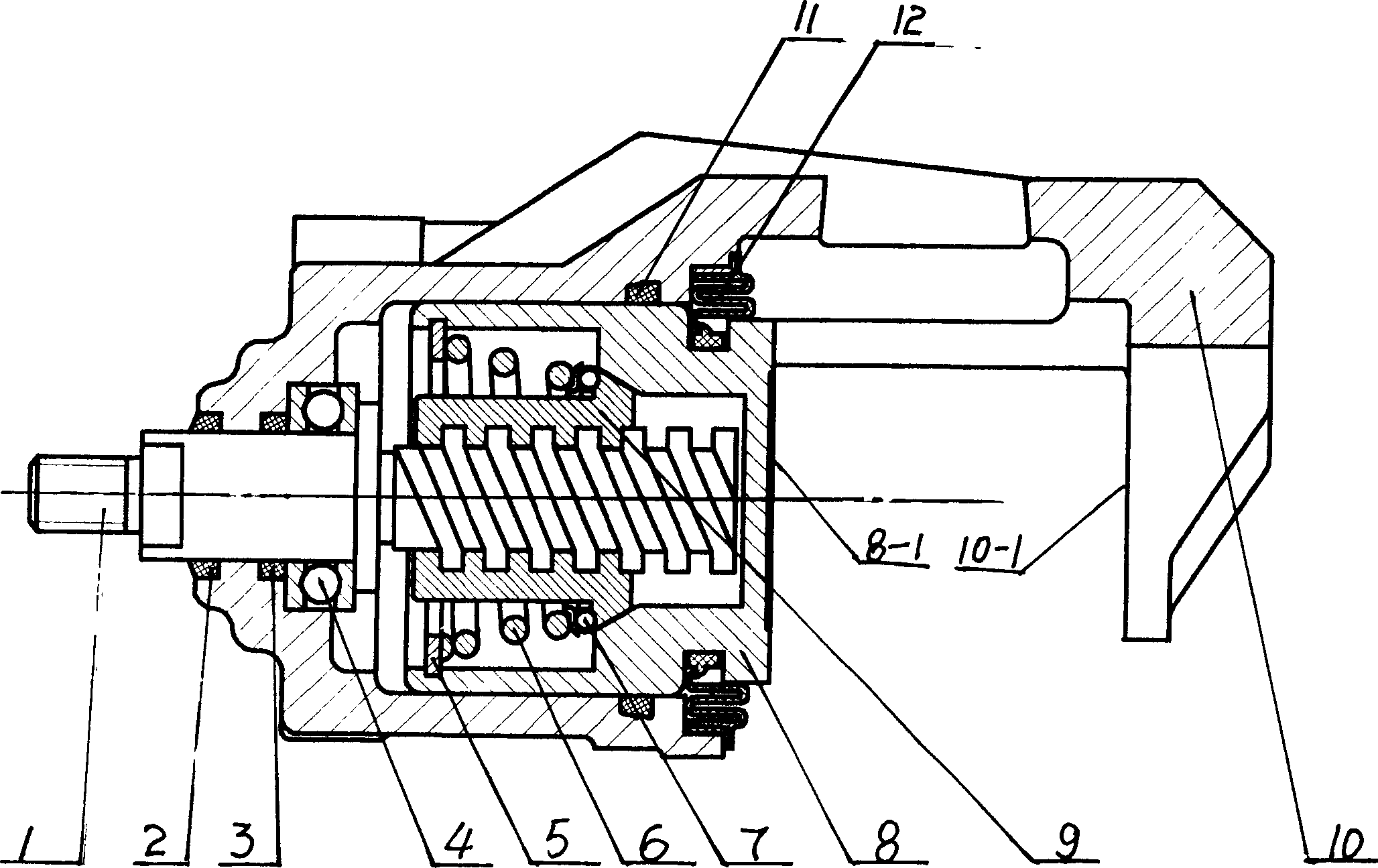

[0007] The specific implementation of the present invention will be further described in conjunction with the accompanying drawings and examples.

[0008] see figure 1 , the present invention includes: rotating shaft 1, dustproof ring 2, rotating shaft seal ring 3, thrust bearing 4, inner circlip 5, truncated cone coil spring 6, thrust bearing 7, piston 8, rectangular nut 9, cylinder body 10, piston seal Ring 11, piston dust-proof ring 12, piston 8 is housed in the cylinder body 10, and the piston 8 has a closed outer end wall 8-1, which together with the brake jaw 10-1 provided on the cylinder body 10 constitutes a clamping friction plate The braking surface of the mechanism is equipped with an automatic ejection and automatic compensation device composed of a screw, a rectangular nut, and an elastic element. It has a rotating shaft 1 that can rotate but cannot move axially. The brake cable is connected and realizes interlocking. One end of the shaft 1 provided with a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com