Tuyere raceway sampling and measuring device

A technology of measuring device and swirling area, applied to the measuring device, in the field of online sampling of tuyere swirling area, can solve the problems of high wind pressure, large blast furnace volume, bulky sampling equipment, etc., and achieve the effect of small deflection and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

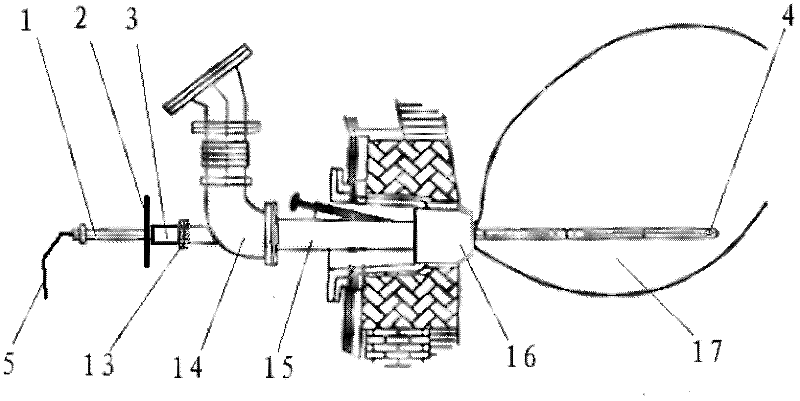

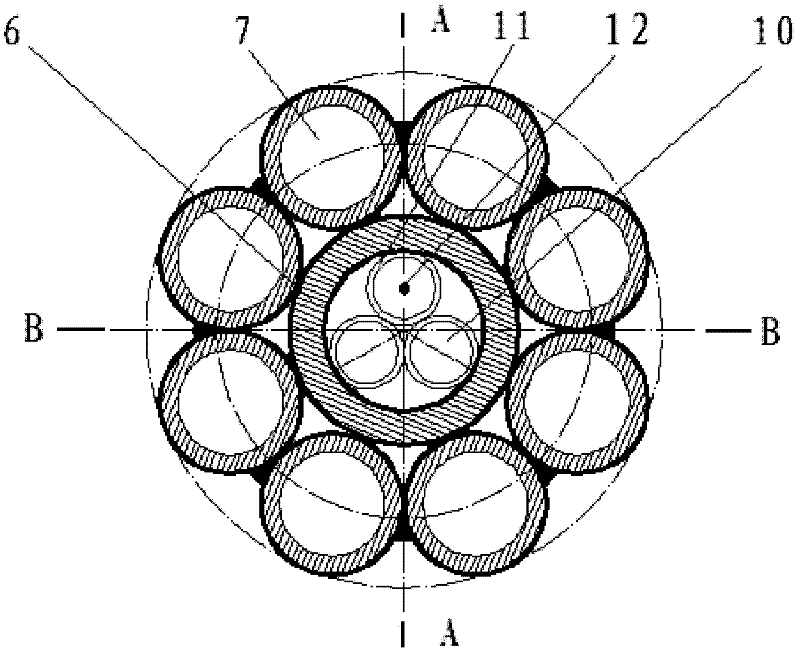

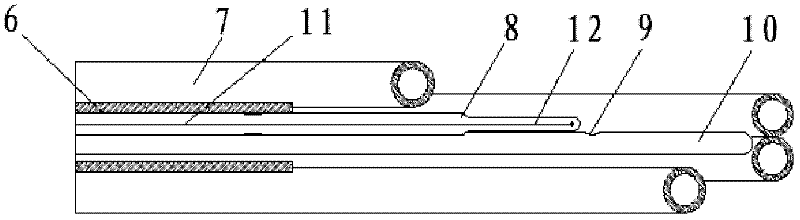

[0019] As shown in the figure, the sampling and measuring device for the tuyere swivel area of this embodiment includes a sampling rod 1, a protective cover 2, a tuyere connecting pipe 3, a connecting pipeline 5, a central pipe 6, a cooling pipe 7, a thermocouple protection pipe 8, a gas Sampling port 9, gas sampling pipe 10, nitrogen protection pipe 11, thermocouple and compensation wire 12, large tuyere cover 13, bent pipe 14, straight blowing pipe 15, tuyere 16, tuyere swirl area 17.

[0020] The sampling rod 1 is welded by the central pipe 6 and the cooling pipe 7 surrounding it. The cooling pipe 7 is divided into a water inlet pipe and a water outlet pipe at the cross section of the front end 4 of the sampling rod. In this embodiment, there are altogether eight pipes, that is, four water inlet pipes and four water outlet pipes, the water inlet and outlet pipes are arranged at intervals around the center pipe 6 to ensure that the cooling effect is uniform and stable. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com