High temperature hot blast furnace

A high-temperature hot blast stove and blast furnace technology, applied to brick blast furnaces, etc., to achieve the effects of continuous gas supply process, optimization of wind temperature factors, and size reduction

Active Publication Date: 2012-08-22

SHANDONG PROVINCE METALLURGICAL ENG CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But, the weak point of the first method is: 1. because it is perforated on the sidewall of the high temperature zone of hot blast stove, it is bigger to the intensity influence of hot blast stove shell, is not suitable for transformation

2. Due to its high installation position, the installation and maintenance of the equipment are extremely inconvenient

3. Due to the low utilization rate of the effective space in the furnace and the problem of easy air leakage in the internal combustion hot blast stove, there is a tendency to be replaced by the top combustion hot blast stove. Therefore, the popularization and application of the above method is increasingly restricted

4. If you try to apply the above method to a top-fired hot blast stove, the gas flow will definitely affect the uniform distribution of the pressure field in the combustion chamber, causing uneven heating of the regenerator and resulting in unsatisfactory final hot blast temperature

As for the second method, from the point of view of energy saving, its effect is relatively ideal, but when the primary purpose is to increase the temperature of the hot air produced by the hot blast stove, it is only a limited improvement and cannot reach To greatly increase the temperature of the hot air

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0029] In practical applications, it may be most appropriate to heat all the combustion air of the main burner by the above method and all the gas of the main burner to be heated conventionally at the flue.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

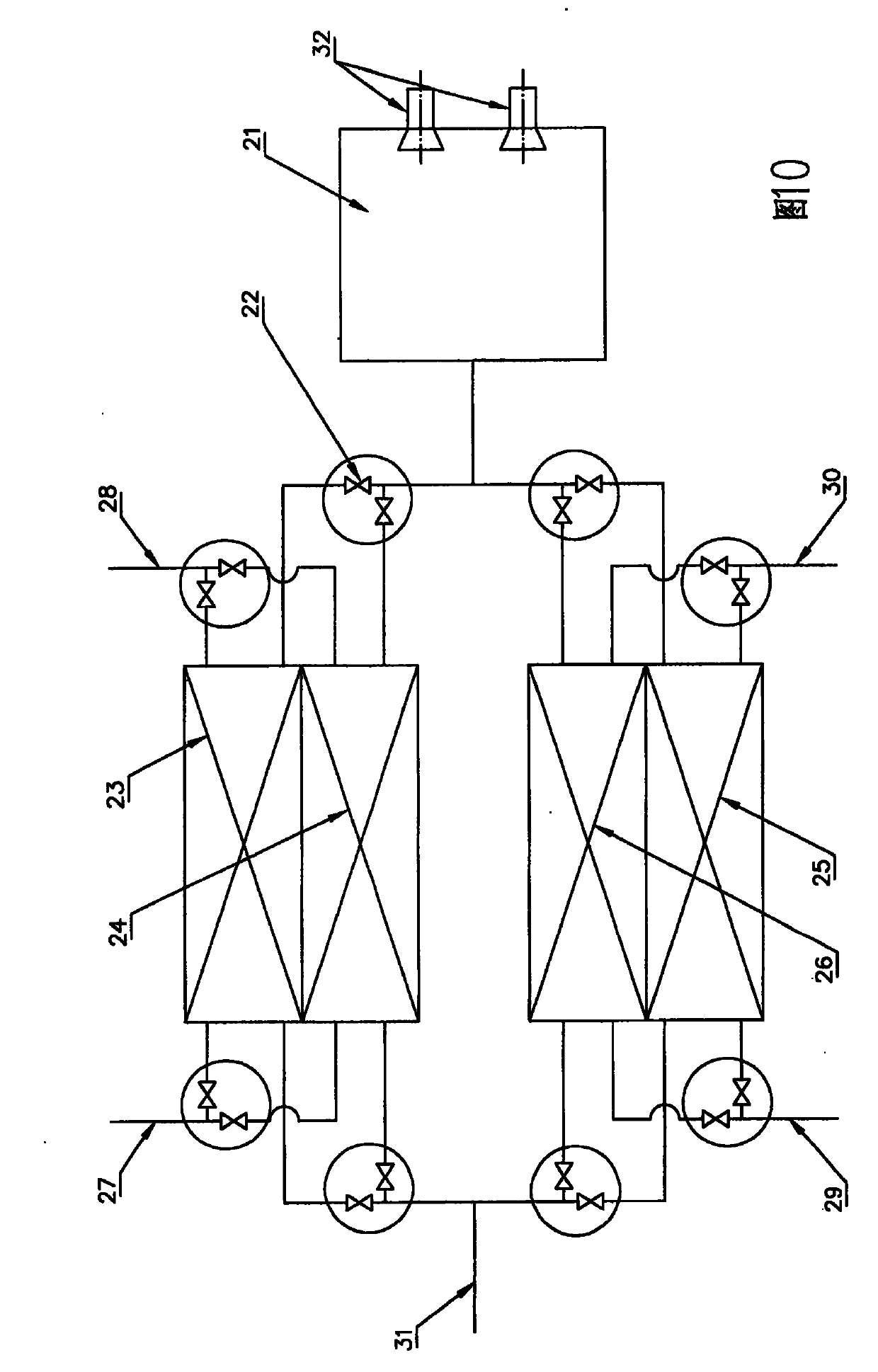

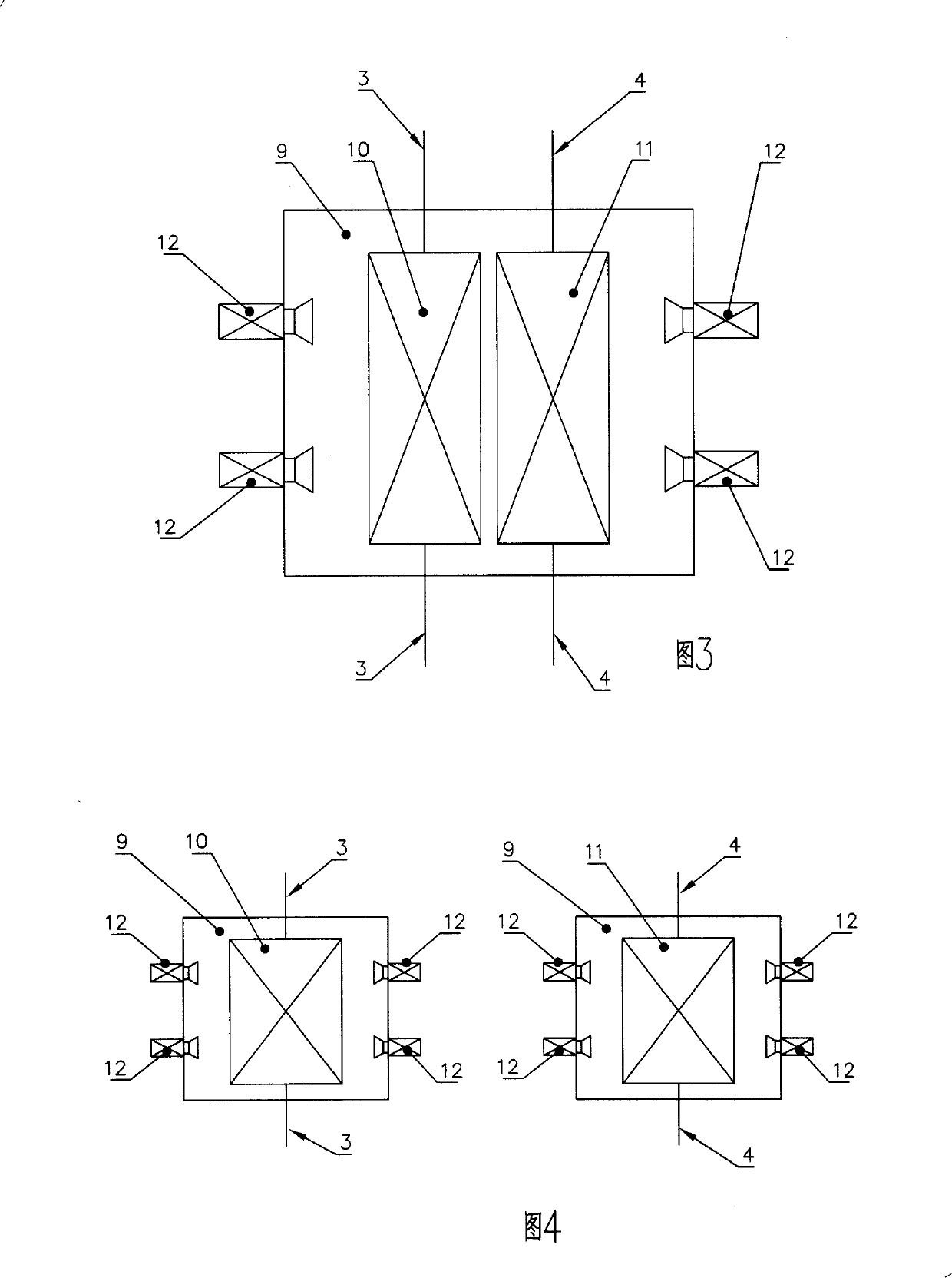

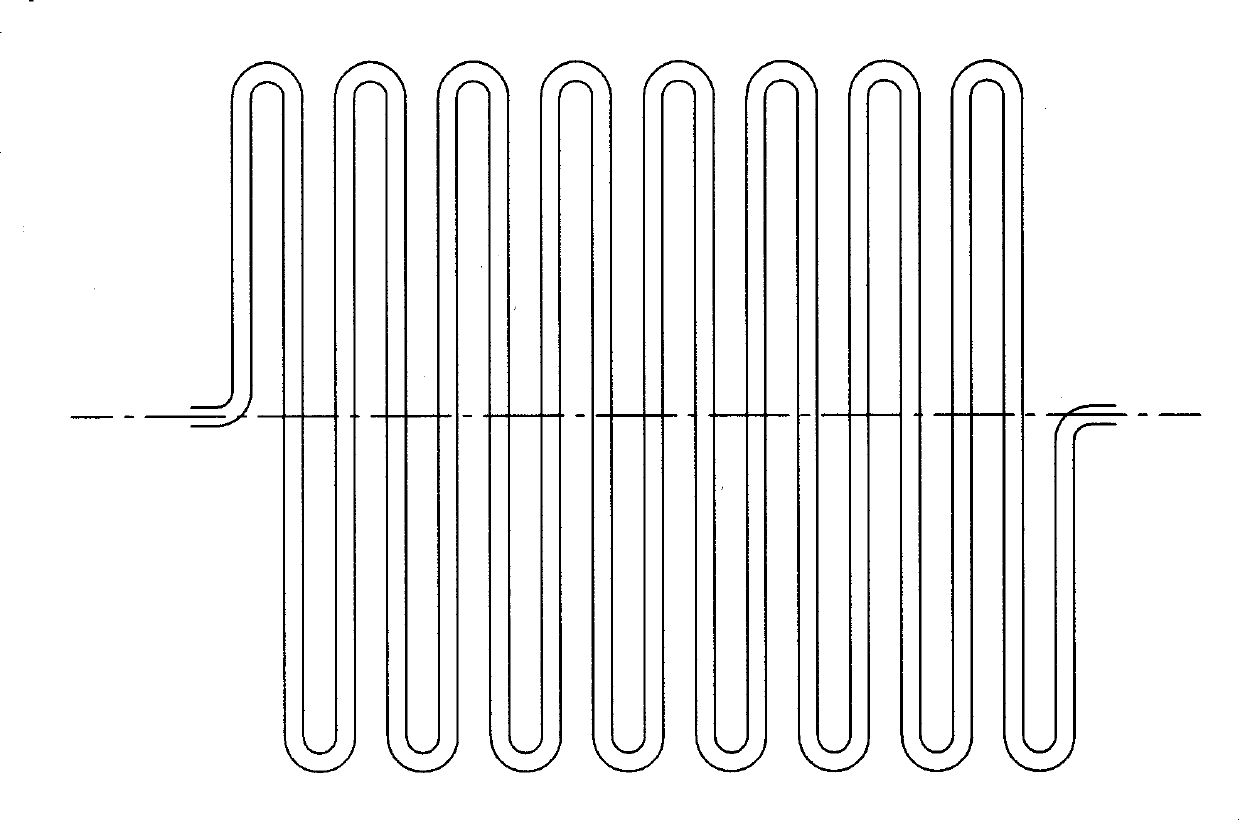

The present invention relates to a high temperature hot blast furnace for further resolving the problem of improving temperature of high temperature hot blast furnace to satisfy arbitrary temperature required by high temperature hot blast furnace, and the high temperature hot blast furnace is suitable for rebuilding to facilitate the installation and maintain. The main technical character comprises, adding a pre-heating device (1) for gas and / or combustion air, which can conveniently improve the temperature of blast of the high temperature hot blast furnace. Meantime, the invention has advantages that the temperature setting value of gas and / or combustion air is convenient to adjust and tend to be best match of operation condition of the hot blast furnace; temperature grads, pressure field and fluid field in the main chamber of the hot blast furnace are not basically influenced which conduce stability of the hot blast furnace; the supply process of gas and / or combustion air is stable and continuous; and afterheat utilizing method is not excluded.

Description

Technical field [0001] The invention relates to a high-temperature hot blast stove used in a blast furnace. Background technique [0002] Blast furnace smelting requires hot air with a sufficiently high temperature, and a hot blast stove is an essential device for providing such hot air. The hot blast stove currently used in industry is composed of a furnace shell, a refractory lining, a combustion device, a regenerator and a channel system. Restricted by the calorific value of fuel and the initial temperature of fuel and combustion-supporting air, the usual air supply temperature of existing hot blast stoves is generally around 1000-1200°C, which cannot meet higher process requirements. What needs special attention is that at such a high temperature, it is very difficult to increase the temperature; at the same time, even if it is only increased by a few tens of degrees, it is very beneficial to the smelting process. Therefore, it was proposed to increase the use of preh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21B9/04

Inventor 姚朝胜黄东生任浩

Owner SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com