Motor with reduction mechanism and power seat motor with reduction mechanism

A technology of reduction mechanism and motor box, applied in the direction of movable seats, components with teeth, electromechanical devices, etc., to achieve the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] An embodiment of the present invention will now be described with reference to the accompanying drawings.

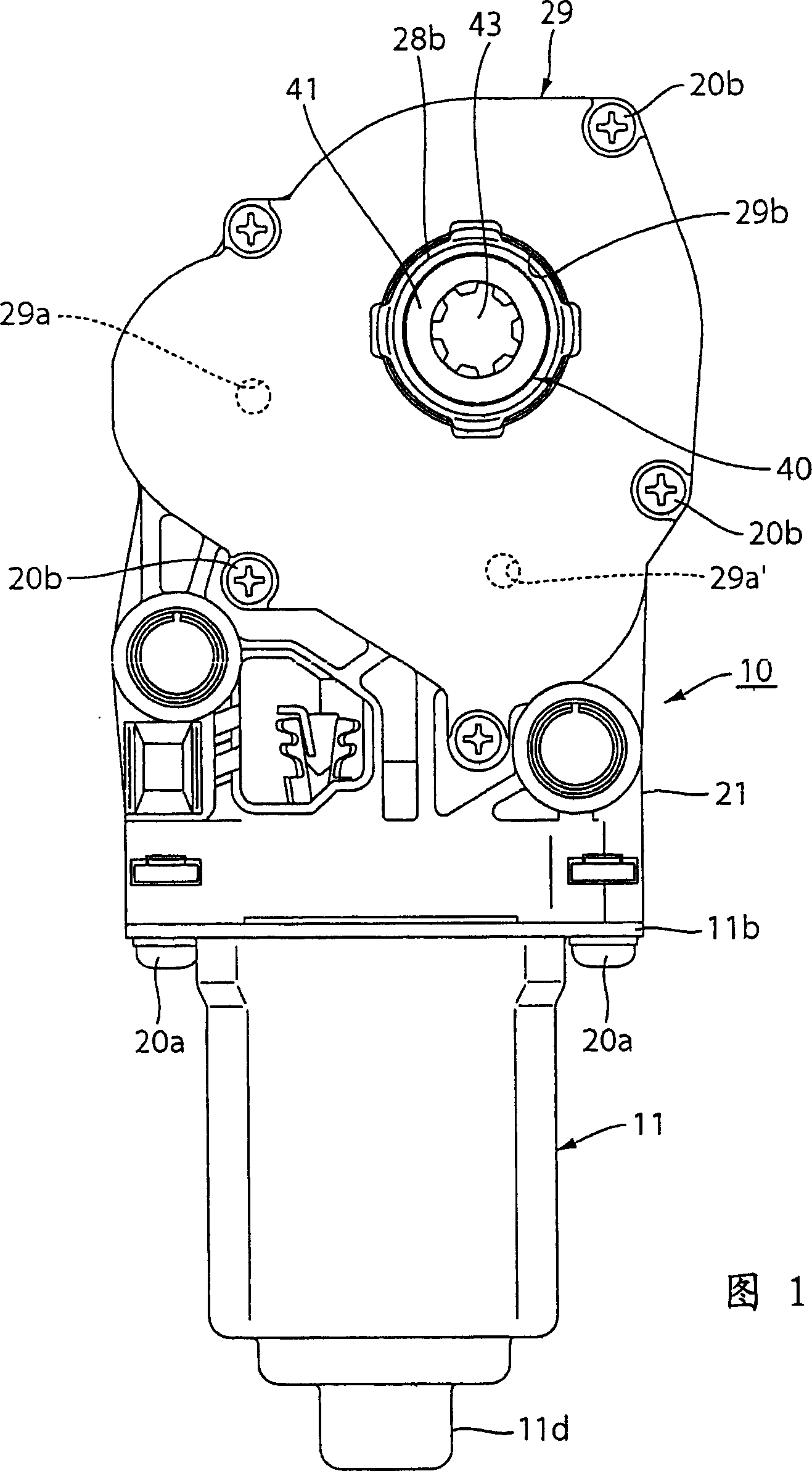

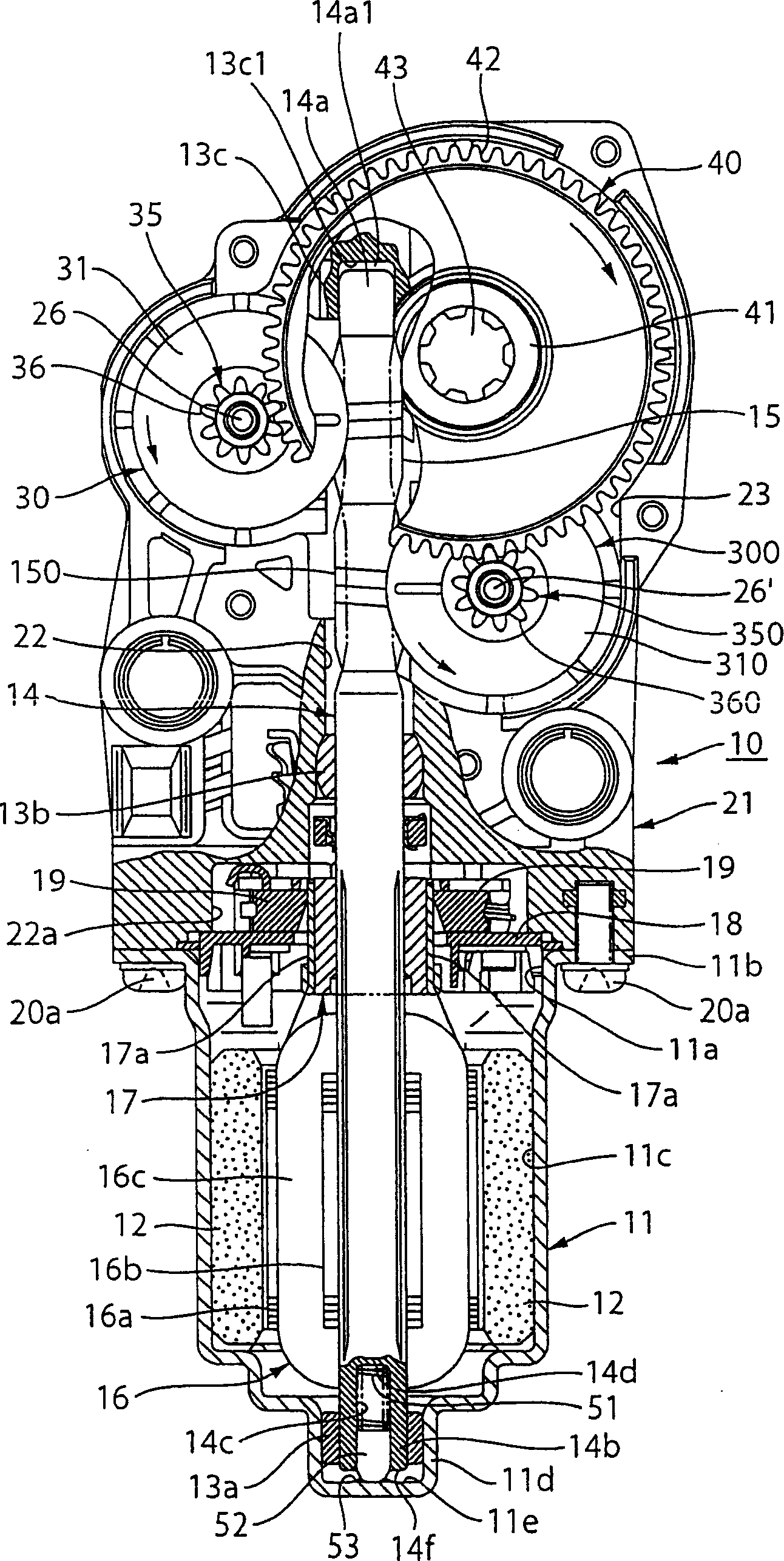

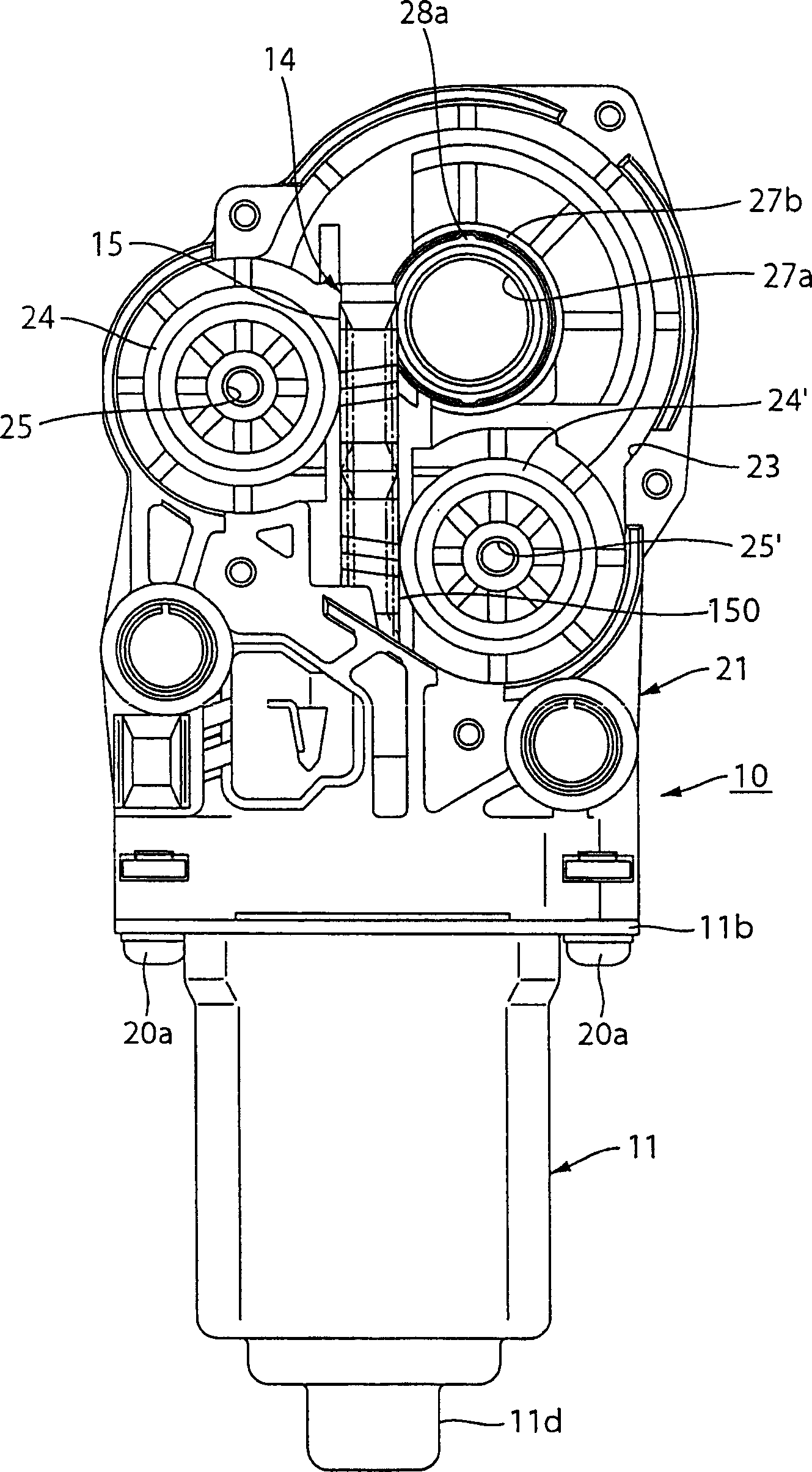

[0032] Fig. 1 is a plan view of a motor with a reduction mechanism according to an embodiment of the present invention; figure 2 is the sectional view of the motor; image 3 is the plan view of the motor after the gearbox of the motor is removed; Figure 4 It is an enlarged sectional view of the main part of the motor; Fig. 5 is a schematic diagram when the motor shaft used in the motor does not rotate; Image 6 is a schematic diagram when the motor shaft used in the motor rotates forward; FIG. 7 is a schematic diagram when the motor shaft used in the motor rotates reversely. In addition, a vehicle seat (electric seat 1 ) as shown in FIG. 8 for explaining a vehicle device having a conventional motor is also used here to explain the present invention.

[0033] Figure 1, figure 2 with image 3 As shown, a motor 10 for an electric seat with a reduction mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com