Piezoelectric ceramic metal composite plate in-plane vibration linear ultrasound motor

A linear ultrasonic motor, metal composite plate technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Broad application prospects, compact structure, easy installation and repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

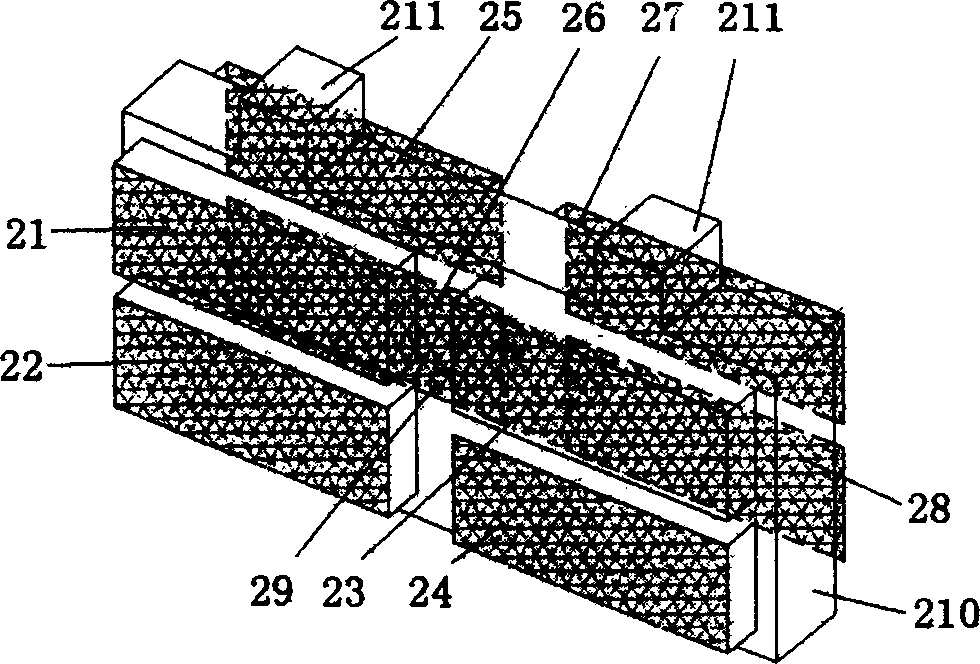

[0034] Embodiment one is biped linear drive mechanism

[0035] The main feature of this structure is that the stator is composed of a metal plate 48 and 8 piezoelectric ceramic sheets 41 symmetrically pasted on both sides of the metal plate. The stator drives the mover 42 to move linearly through two driving feet 43 . The elastic constraint (spring pad) 46 exerts a force on the stator through the central hole 45 on the stator, so as to maintain an appropriate preload between the stator and the rotor. Another solution for applying the preload is to apply elastic constraints 48 on the three side surfaces of the metal plates of the stator. In order to increase the life of the motor, a wear-resistant layer can be coated on the driving surface of the driving foot, and a friction material 44 can be pasted on the contact surface of the mover 42 .

Embodiment 2

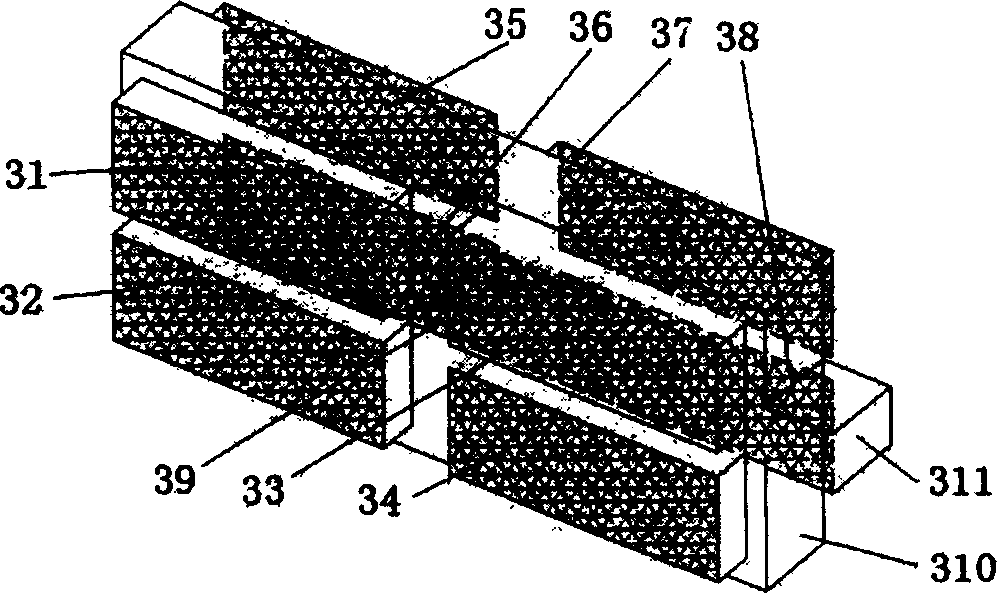

[0036] Embodiment two is a single foot linear drive mechanism

[0037] The main feature of this structure is that the stator is composed of a metal plate 56 and 8 piezoelectric ceramic sheets 51 symmetrically pasted on both sides of the metal plate. The stator drives the mover 53 to move linearly through a driving foot 54 . Elastic restraints (spring pads) 52 apply force to the stator on three side surfaces of the stator metal plate to maintain a proper preload between the stator and the rotor. In order to increase the life of the motor, a wear-resistant layer can be coated on the driving surface of the driving foot, and a friction material 55 can be pasted on the contact surface of the mover 53 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com