Half screw pile and processing method and apparatus therefor

A processing device and processing method technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inapplicability, high cost, inconvenient construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

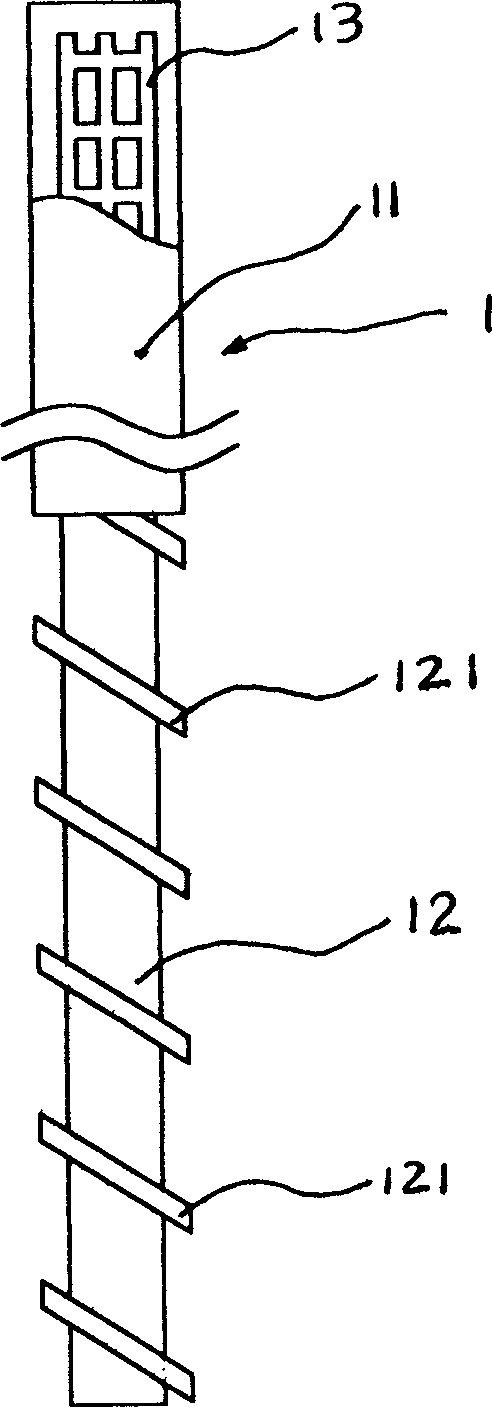

[0045] figure 1 Shown is half screw pile 1, and this pile is made of two parts of integral structure, and the top is the pile foundation 11 (cylindrical structure 11 for short) of straight pile cylindrical structure, and the bottom is the pile foundation 12 of threaded structure (being called for short threaded pile foundation 11). Shaped structure 12); Its design is according to the distribution situation that it is arranged under the soil layer and is the distribution of the shape of an inverted pyramid. The pile has sufficient bearing capacity, and the semi-screw pile 1, its cylindrical structure 11 accounts for about 1 / 3 of the total pile length, and the threaded structure 12 accounts for about 2 / 3 of the total pile length. Pile body with maximum bearing capacity.

[0046] In the half-screw pile 1, screw teeth 121 at a certain inclination angle are uniformly distributed on the threaded structure 12, and the radial distance of the threaded structure 12 is equal to the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com