Self-wringing mop

A mop and handle technology is applied in the field of reverse locking devices, which can solve the problems of increasing processing cost and manufacturing cost, and achieve the effects of reducing manufacturing cost, low structure and simple cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

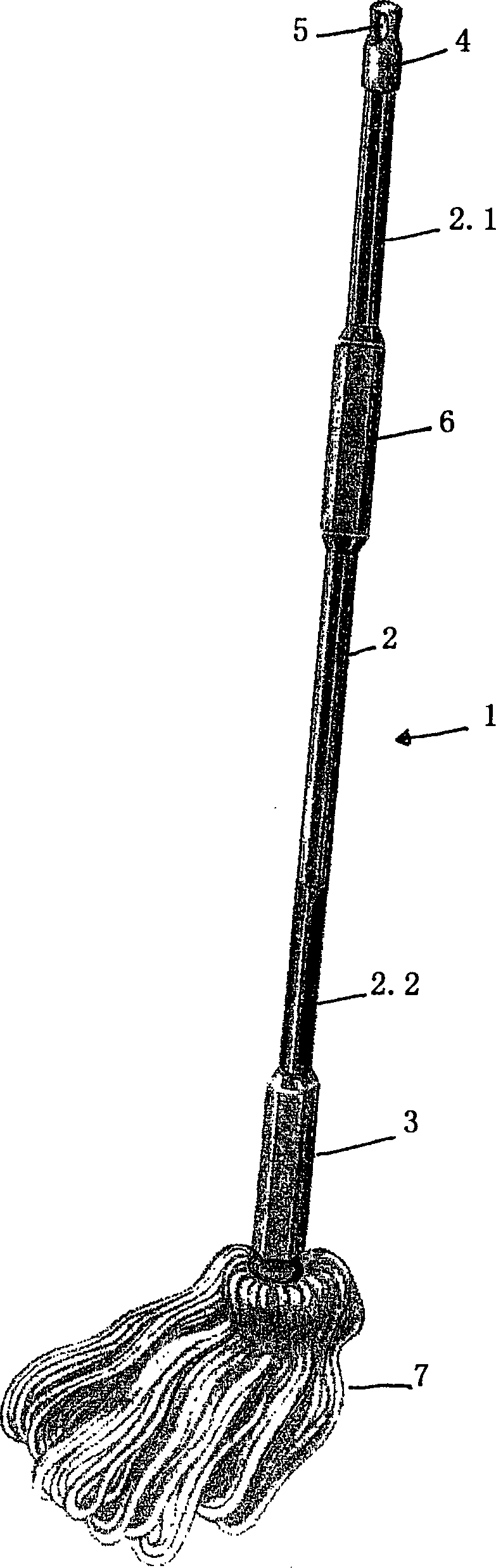

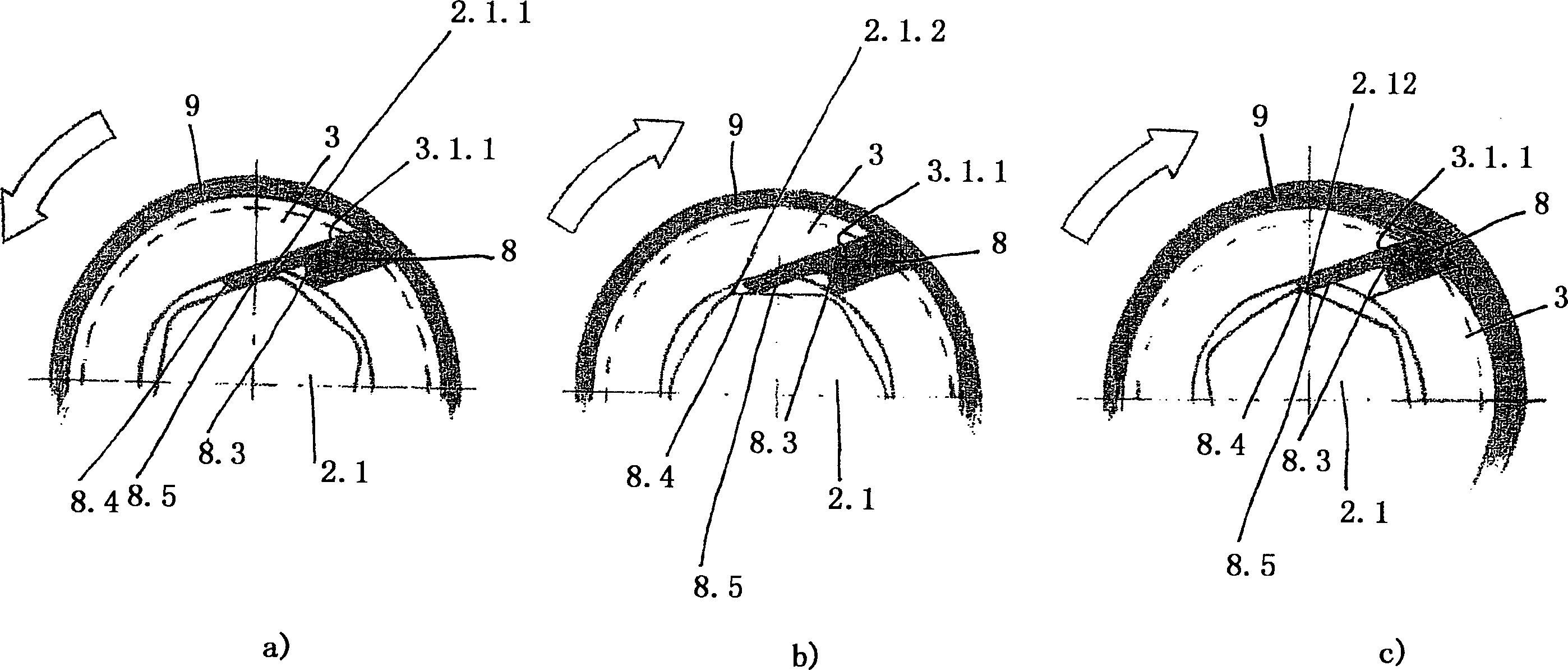

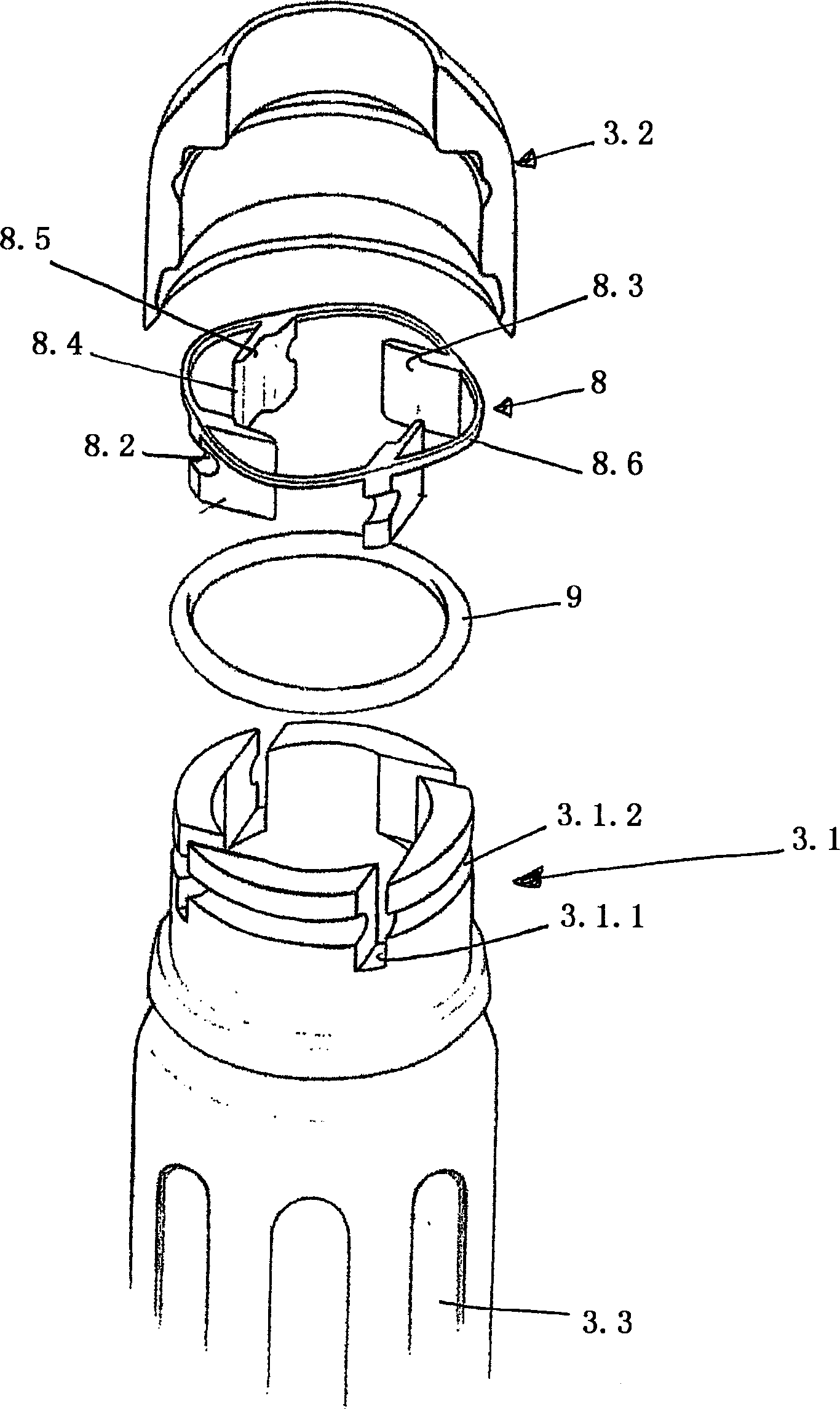

[0026] exist figure 1A self-squeezing mop 1 according to the invention can be seen in the figure. The self-wringing mop 1 according to the invention has a handle 2 and an actuating sleeve 3 arranged rotatably and axially displaceably on the handle 2 . On the upper end of the handle 2 there is a closure cap 4 with a ring 5 for hanging the mop 1 . A handle 6 arranged in the upper region of the handle 2 facilitates the handling of the mop 1 . The handle is preferably provided with ribs or ribs to prevent the hand from slipping. For this purpose, the handle can likewise have, for example, a polygonal, in particular octagonal, outer diameter. There is a mop head 7 at the lower end of the handle 2. In the embodiment shown, without loss of generality, the mop head consists of a cord-like element which is detachably fastened with its lower end to the lower end of the handle 2 and with its upper end to the lower end of the actuating sleeve 3 . In the embodiment shown, the actuatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com