Pivoting piston engine

A piston-type, piston-type technology, applied in the field of oscillating piston-type machinery, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

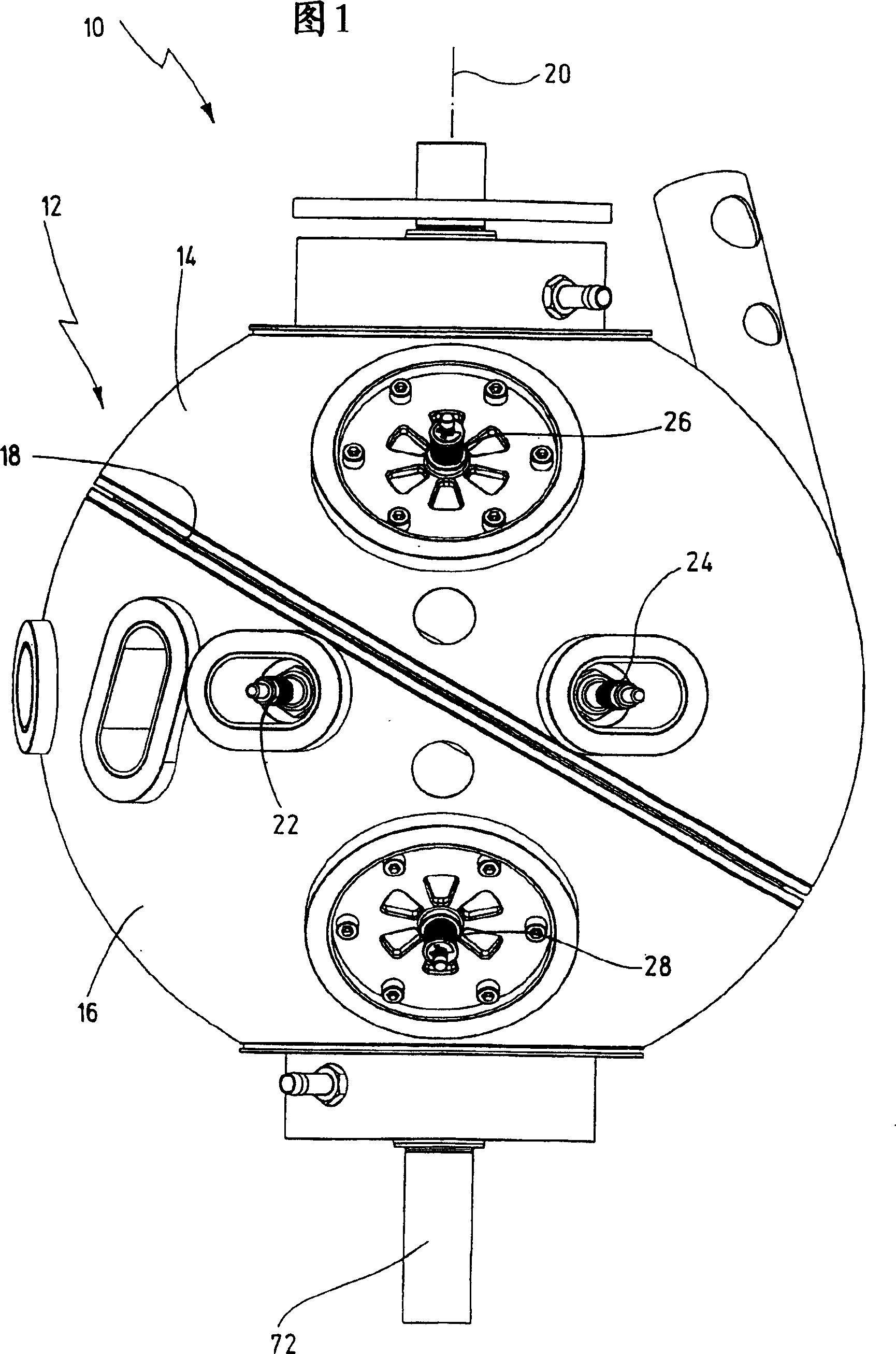

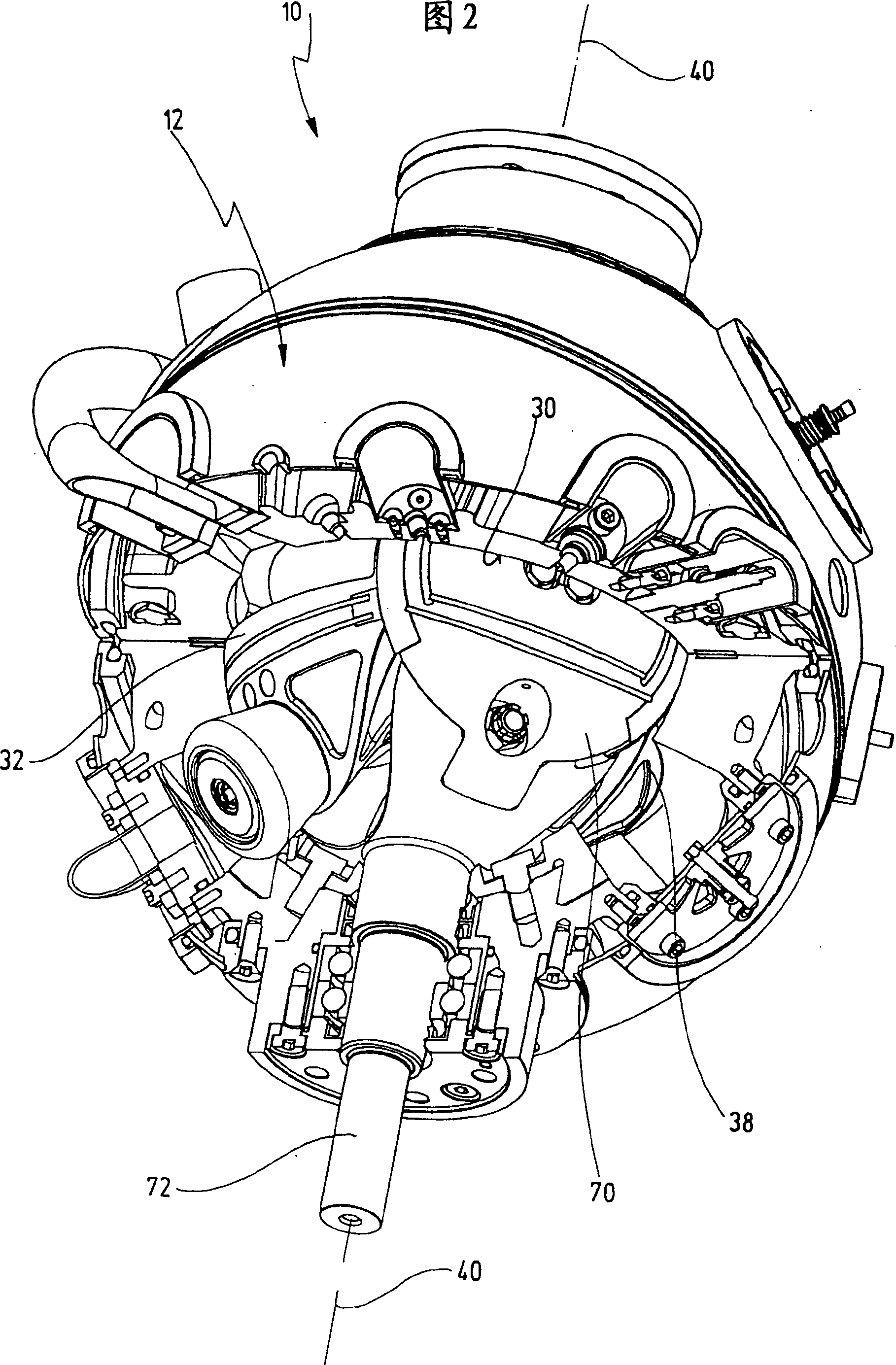

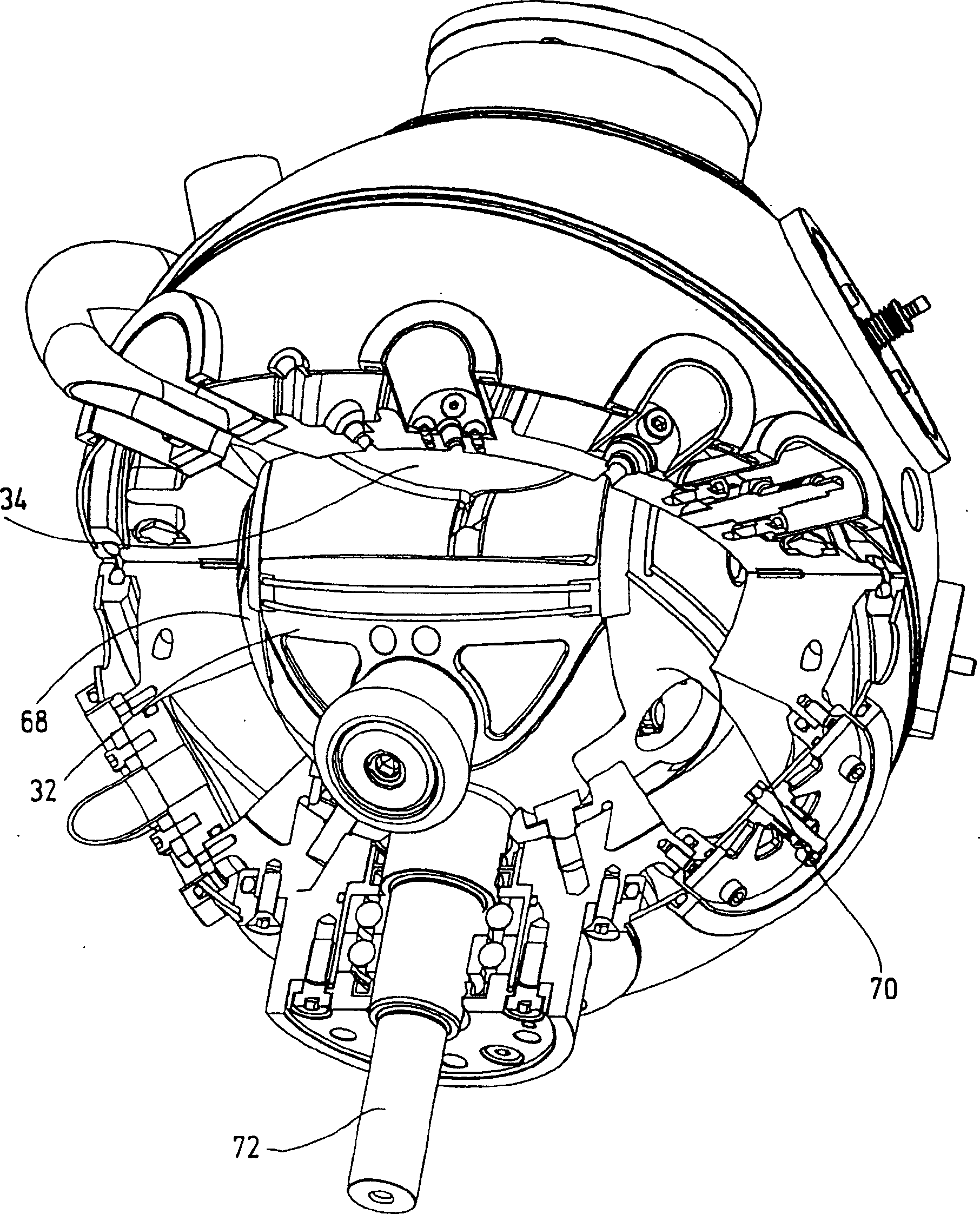

[0057] The design of the oscillating-piston machine generally designated 10 will be described in detail below with reference to FIGS. 1 to 9 . The oscillating piston machine 10 is used, for example and preferably, as an internal combustion engine.

[0058] The oscillating piston machine 10 has a housing 12 consisting of a first half shell 14 and a second half shell 16 .

[0059] The half-shells 14 and 16 are combined along a dividing line 18 which extends not vertically but obliquely with respect to the oscillating piston machine 10 (to be described later) and also to a line of symmetry 20 representing the axis of rotation of the pistons. of. The advantage of this oblique orientation of the boundary line 18 separating the half-shells 14 and 16 from each other is that the technical components located in the casing, such as cross joints and nozzles 22, 24 or valves 26, 28, can be more easily arranged. Arranged in a proper way, these components are not affected by the boundarie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com