Pancake compressor

An opposed type, compressor technology, applied in the direction of pump devices, mechanical equipment, machines/engines, etc., can solve the problem of low efficiency of engine use, achieve efficient use and suppress vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 approach

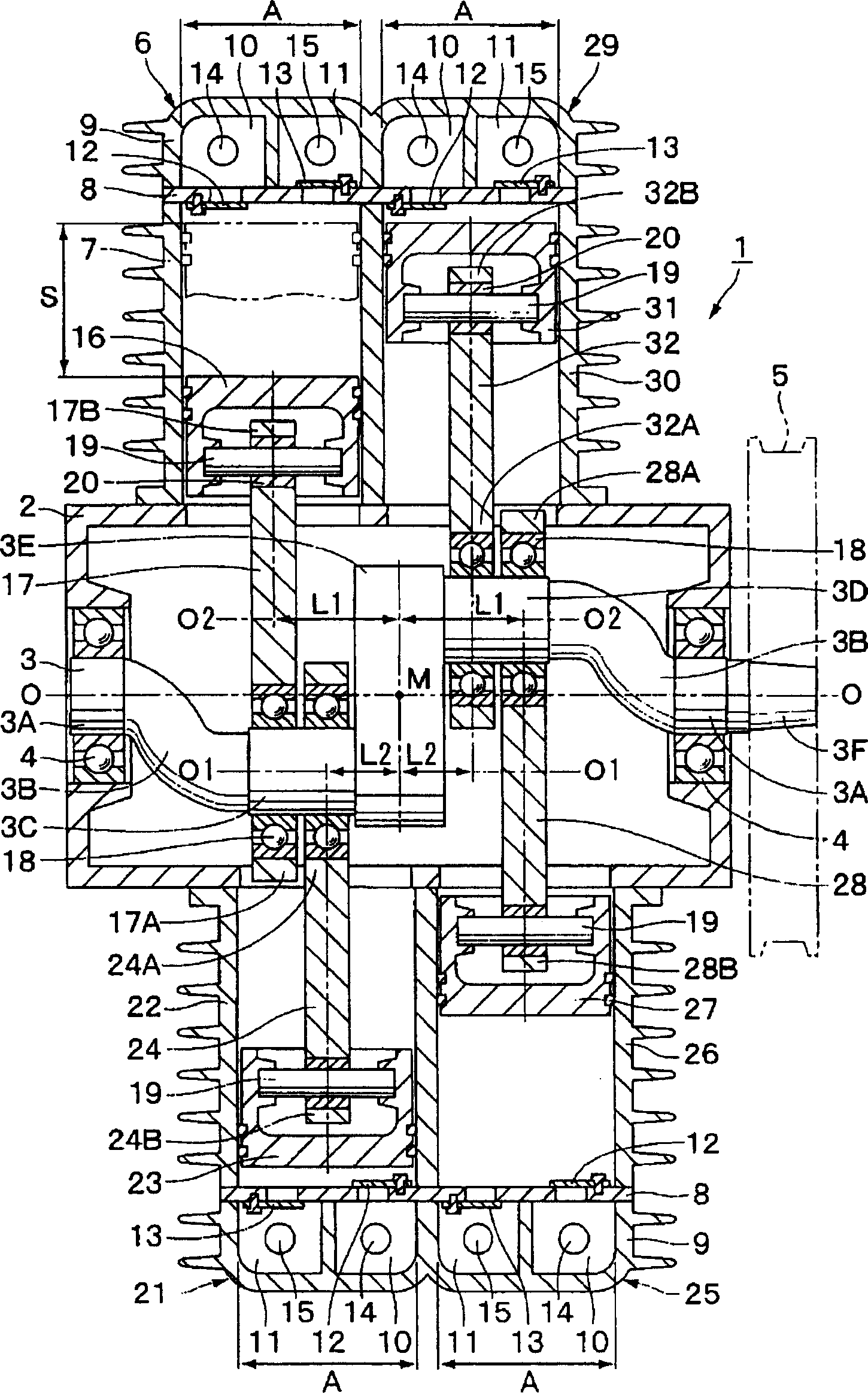

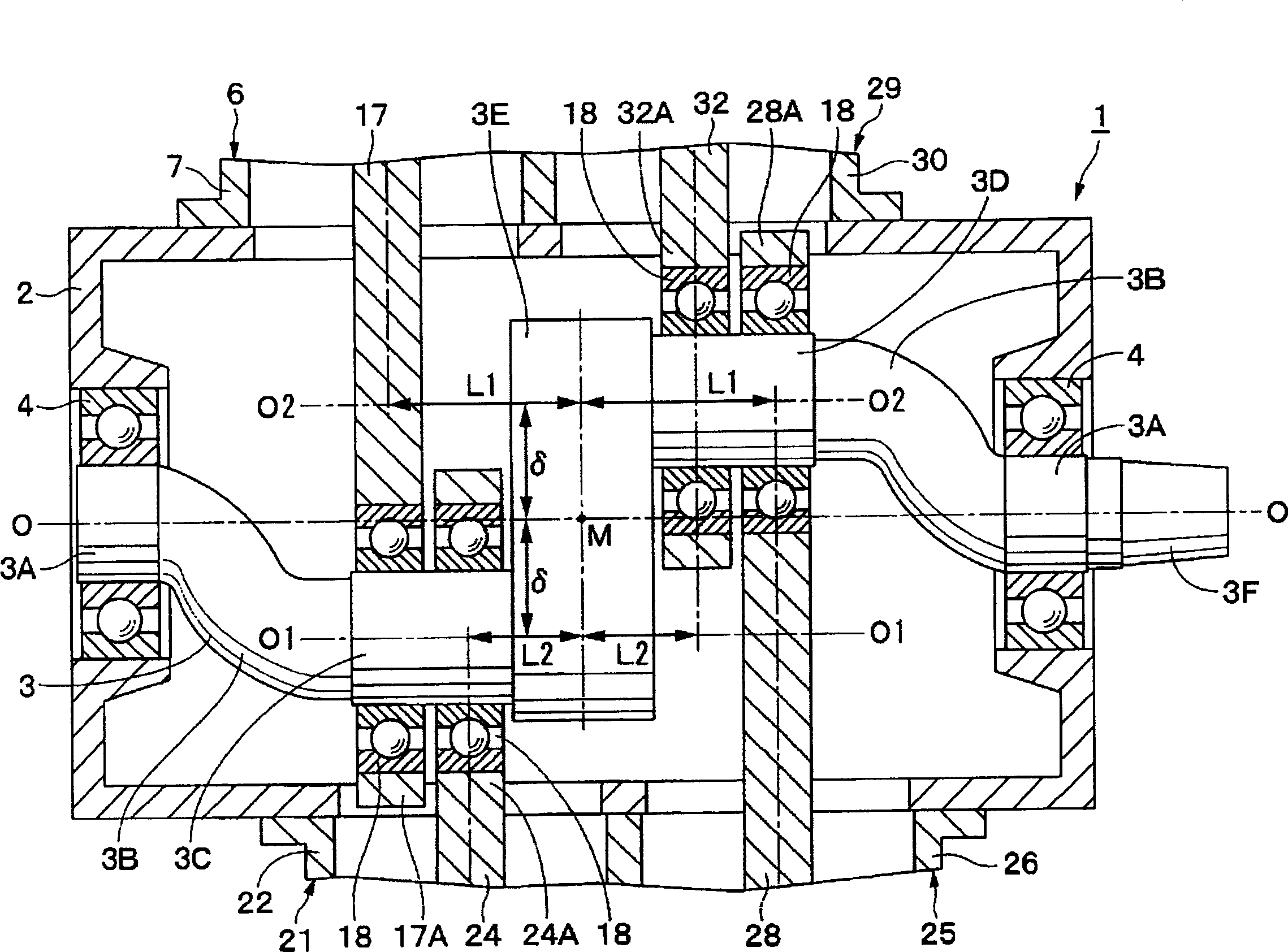

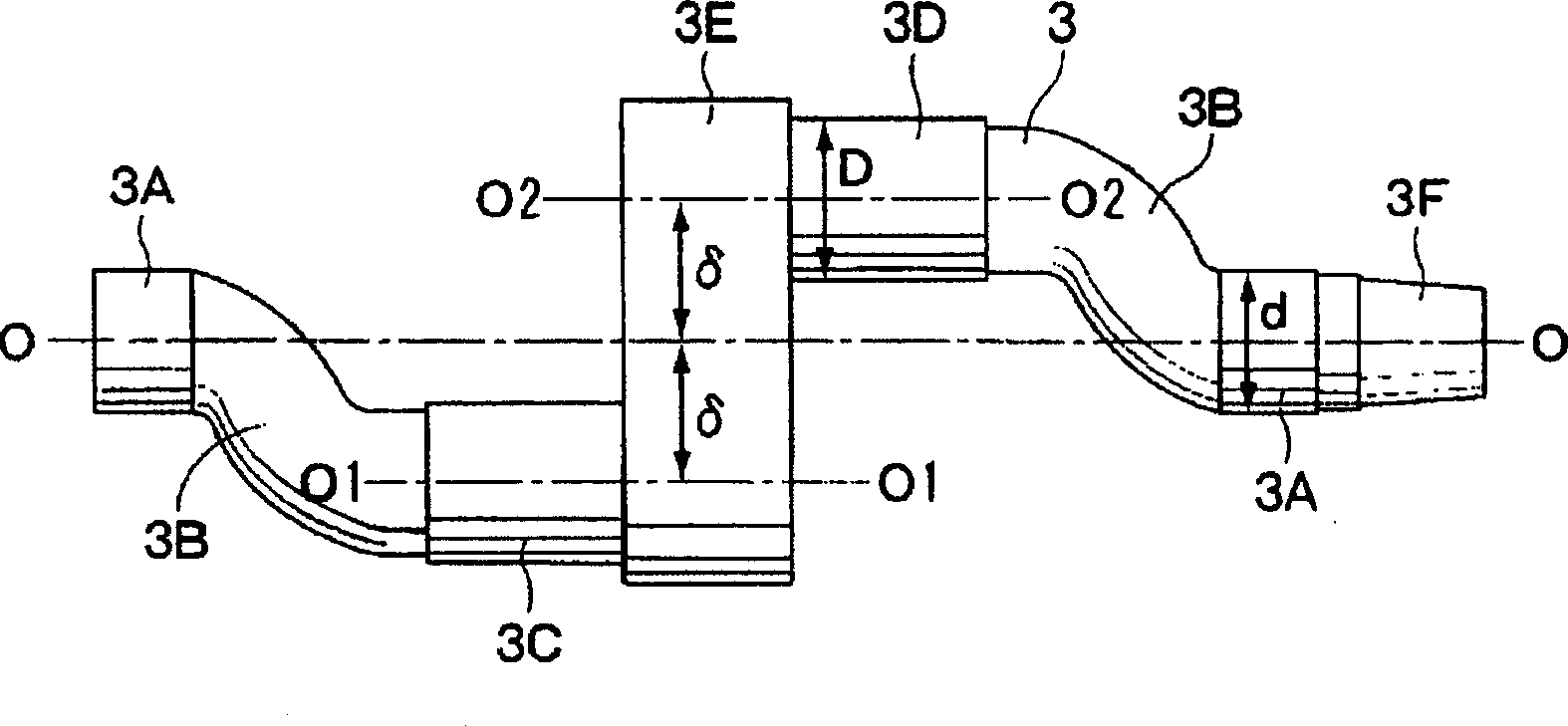

[0094] then, Figure 14 The fourth embodiment of the present invention is shown, and this embodiment is characterized in that it is applied to a six-cylinder compressor. In addition, in this embodiment, the same code|symbol is attached|subjected to the same structural element as the said 1st Embodiment, and the description is abbreviate|omitted.

[0095] 61 is a horizontally opposed six-cylinder air compressor, and this air compressor 61 is composed of a crankcase (not shown), a crankshaft 3, first to fourth compression units 6, 21, 25, 29, and the fifth and sixth compression parts 62 and 66 described later.

[0096] Here, the fifth compression unit 62 is formed substantially in the same manner as the compression unit 6 , and has a cylinder 63 , a piston 64 , and a connecting rod 65 . In addition, the sixth compression unit 66 is disposed on the opposite side in the radial direction from the fifth compression unit 62 , and has a cylinder 67 , a piston 68 , and a connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com