Disk player

A technology for players and drive trays, which is applied in the direction of instruments, record carrier structural parts, and reduction of physical parameters of the carrier. Small, vibration-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

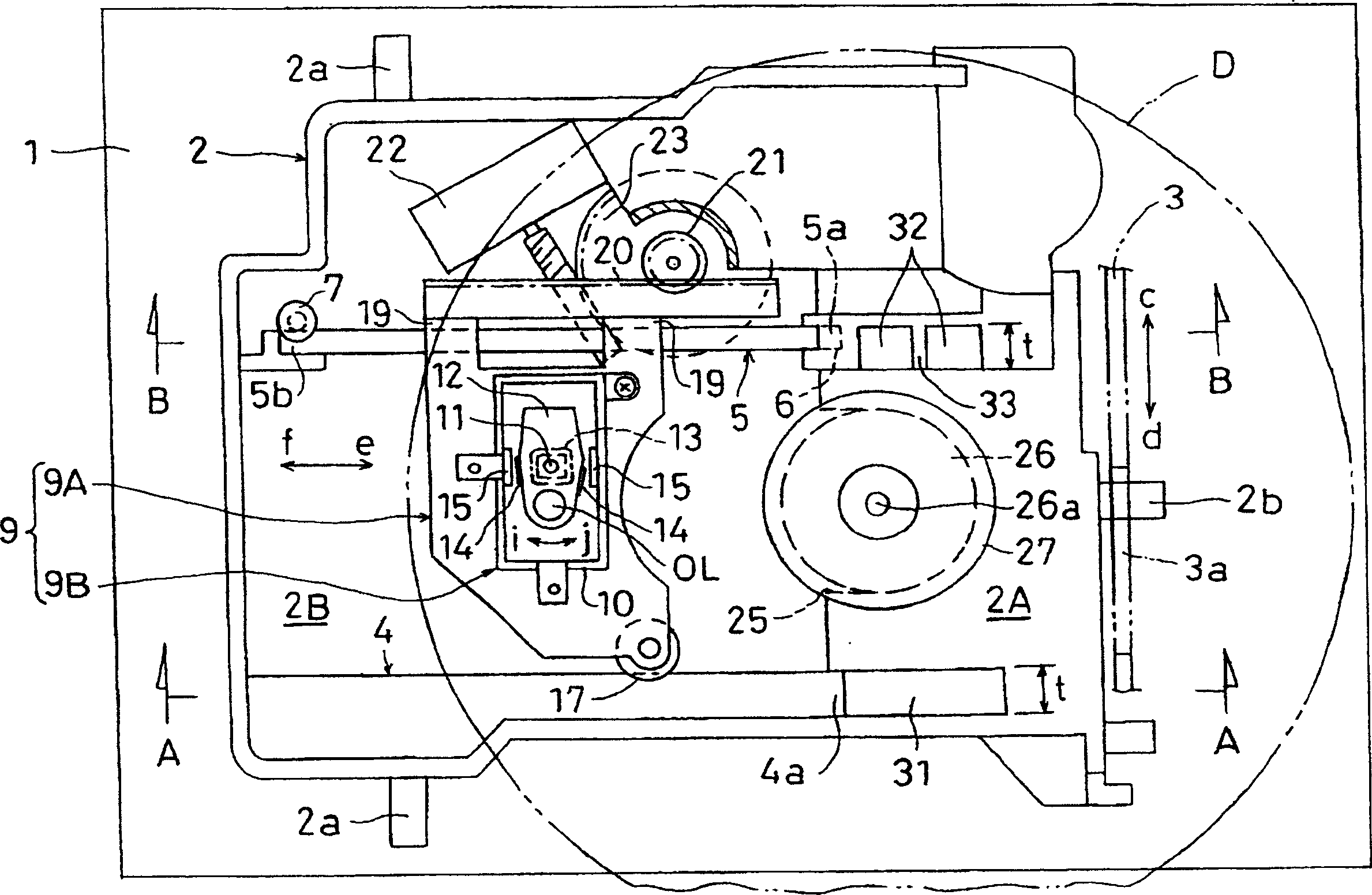

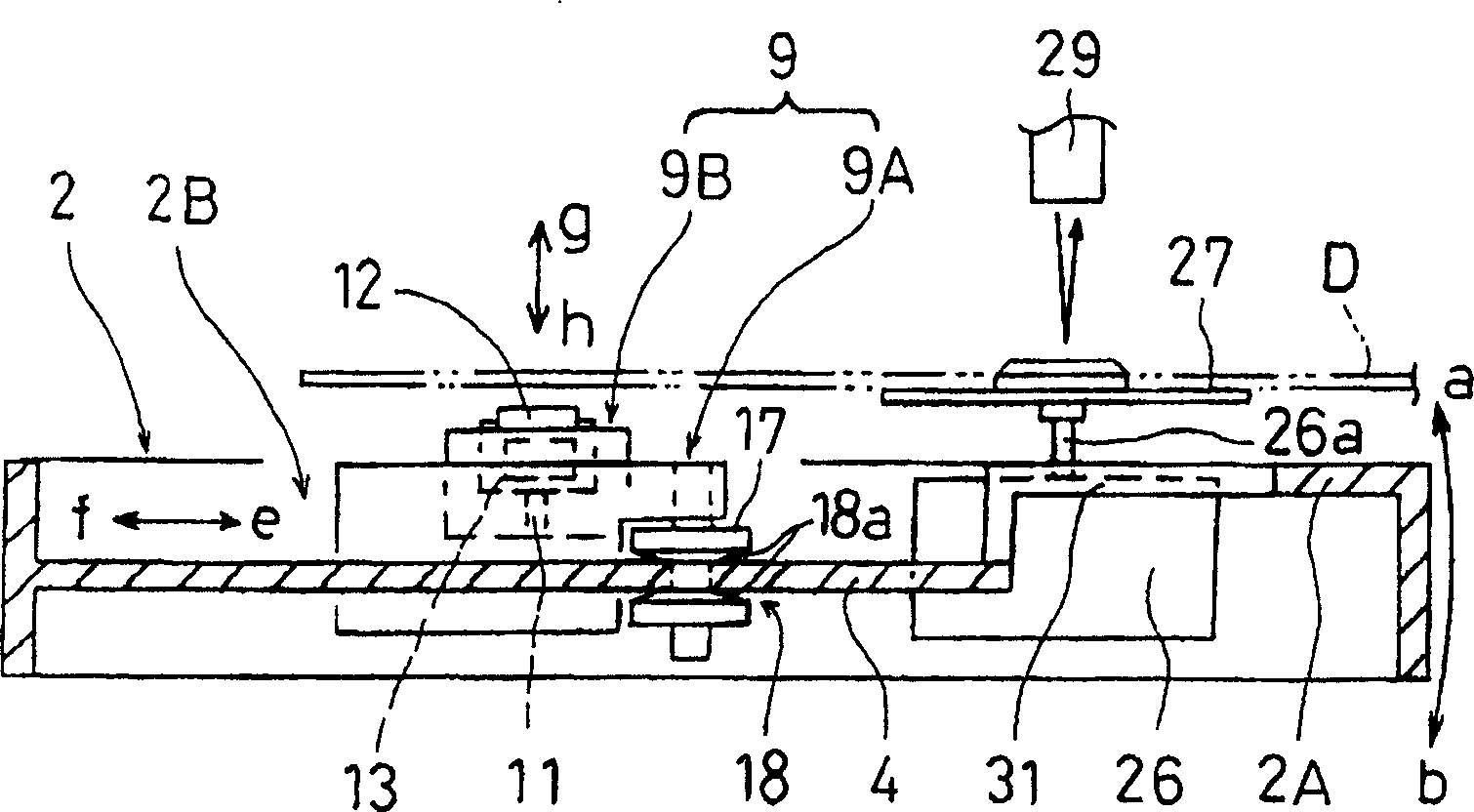

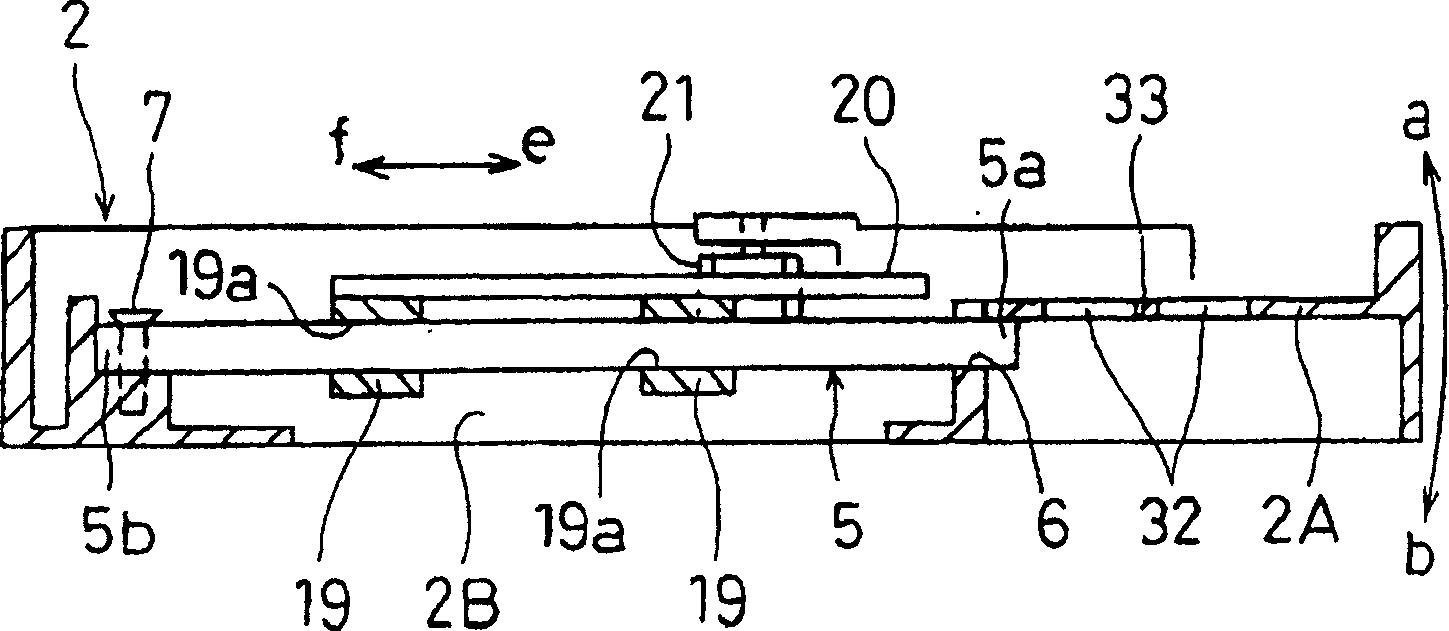

[0037] Figure 1-4 Shows a disk player according to an embodiment of the present invention. Vibration damping holes 31 and 32 are respectively penetratingly provided in the cover plate 2A substantially between the spindle motor fixing recessed groove 25 of the cover plate 2A and the guide shaft 5 . The damping hole 31 is formed to extend from the front end 4 a of the guide rail 4 in the forward direction e, and has the same width as the guide rail 4 . Meanwhile, the damping hole 32 is formed to extend in the forward direction from near the front end 5 a of the guide shaft 5 and has approximately the same width as the damping hole 31 . A reinforcement beam crossing an approximately central portion of the damping hole 32 on the guide shaft side is integrally formed with the cover plate 2A. Since except as stated, this configuration is the same as Figure 5-9 The configurations are substantially the same, and the same parts will be denoted by the same reference numerals, and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com