Additive for livestock feed

A feed additive and additive technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problem of limited feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (Example 1) Production of substances derived from maitake mushrooms

[0055] (1) Dried maitake, dried maitake powder

[0056] Place the artificially cultivated raw maitake fruiting bodies in a greenhouse-type drying room, and blow hot air at about 60°C to 80°C for drying. Starting from the initial temperature of 60°C, the temperature is gradually raised to 80°C, and after heating and drying for about a day, dried maitake mushrooms are obtained. The dried maitake mushrooms are made into powder with a powder making machine.

[0057] (2) Maitake extract

[0058] 10 kg of dried maitake fruiting body powder was treated with 100 L of purified water under pressure at 120° C. for 30 minutes, and then filtered to obtain 60 L of dark brown extract. The liquid was concentrated to 25 L under reduced pressure, and 28 L of 95% ethanol was added at room temperature. After standing for about 18 hours, floating matter was formed on the liquid surface or in the liquid, or dark brown s...

Embodiment 2

[0061] (embodiment 2) modulation of feed additive

[0062] feed additive 1

[0063] Maitake dried powder 5kg

[0064] Lactose 5kg

[0065] Total 10kg

[0066] Feed additive 2

[0067] Dry Maitake Powder 3kg

[0068] Dry Yeast Cell Wall (YCW) 4kg

[0069] Lactic acid bacteria 0.05kg

[0070] Light liquid paraffin 0.2kg

[0071] Lactose balance

[0072] Total 10kg

[0073] Feed additive 3

[0074] Maitake Extract Powder 0.2kg

[0075] Dry Yeast Cell Wall (YCW) 4.0kg

[0076] Light liquid paraffin 0.2kg

[0077] Lactose Balance

[0078] Total 10kg

[0079] The substances in the above formula are mixed evenly and fully, and prepared into feed additives respectively.

[0080] The above-prepared additives can be directly mixed into the feed, and can also be formulated into granules, soft pills, dry pills, etc. according to the needs.

Embodiment 3

[0081] (Example 3) Feed test results and flavor test of meat produced

[0082] (1) Chicken feeding test results

[0083] 0.2% by weight of Feed Additive 1 and Feed Additive 2 were added to Test Group 1 and Test Group 2, respectively, and the group to which no feed additive was supplied was used as a control group and tested for 9 to 10 months. The results are shown in Table 2 below.

[0084] Table 2

[0085] Test group 1

control group

number of chicks

12750

12750

12450

Shipment only

12107

12359

11227

Breeding rate

94.96

96.93

90.18

Average body weight (kg)

2.919

2.934

2.911

age

53.35

52.69

53.06

feed requirement rate

2.085

2.054

2.206

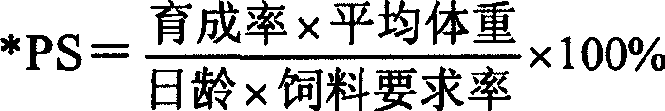

PS*

249.2

262.8

224.3

Abandonment rate

1.51

1.44

1.80

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com