In-situ assembled building net and mounting process

An assembled, on-site technology, applied in the direction of buildings, building components, building structures, etc., to achieve the effect of correct connection position, convenient reinforcement, and increased stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

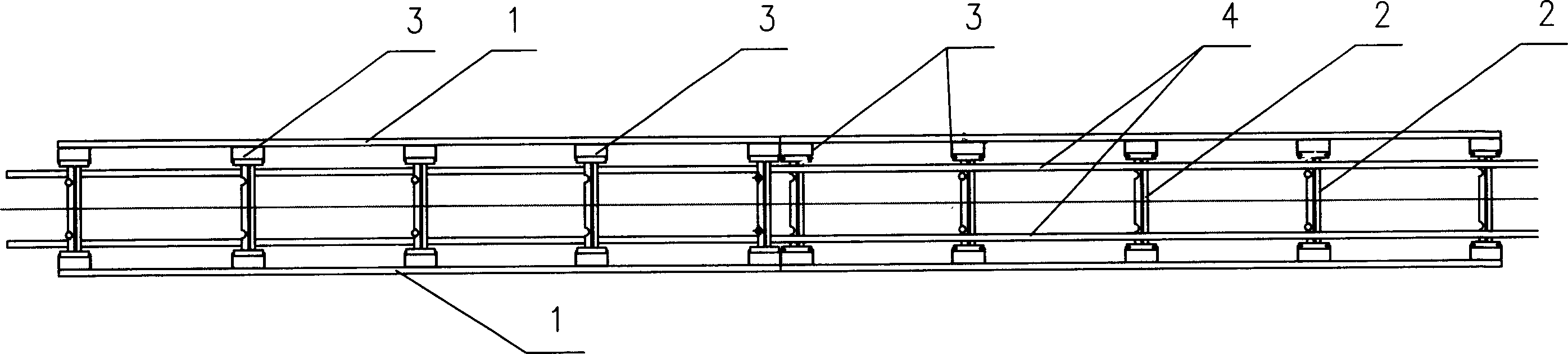

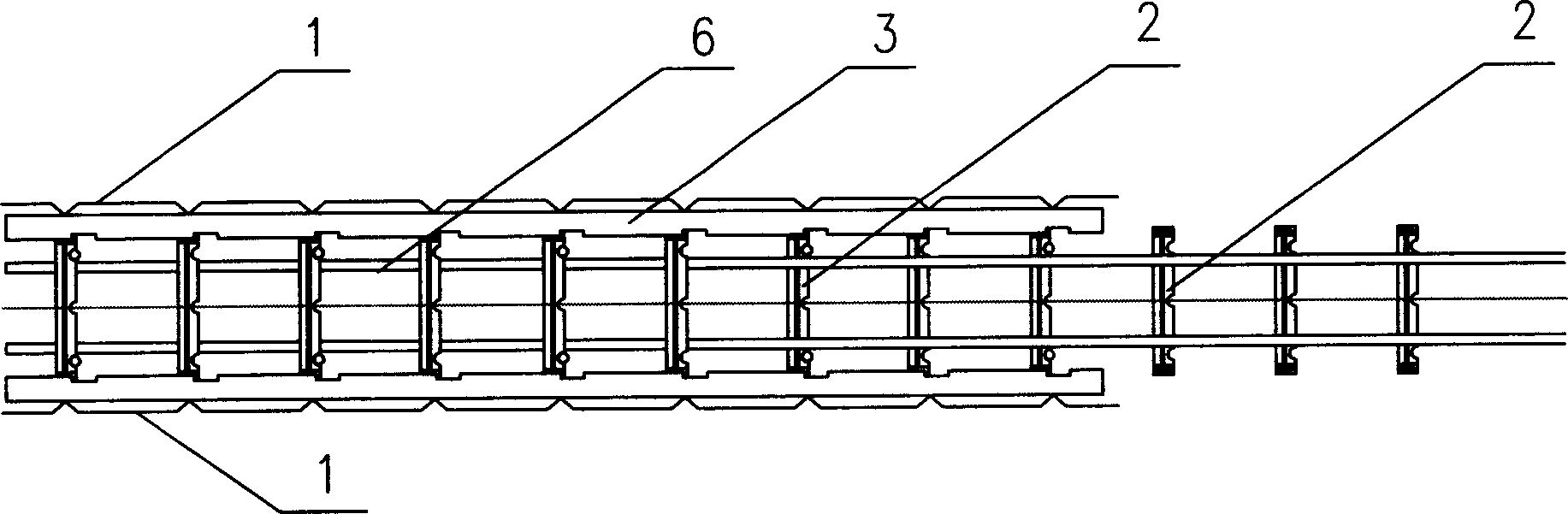

Method used

Image

Examples

Embodiment 2

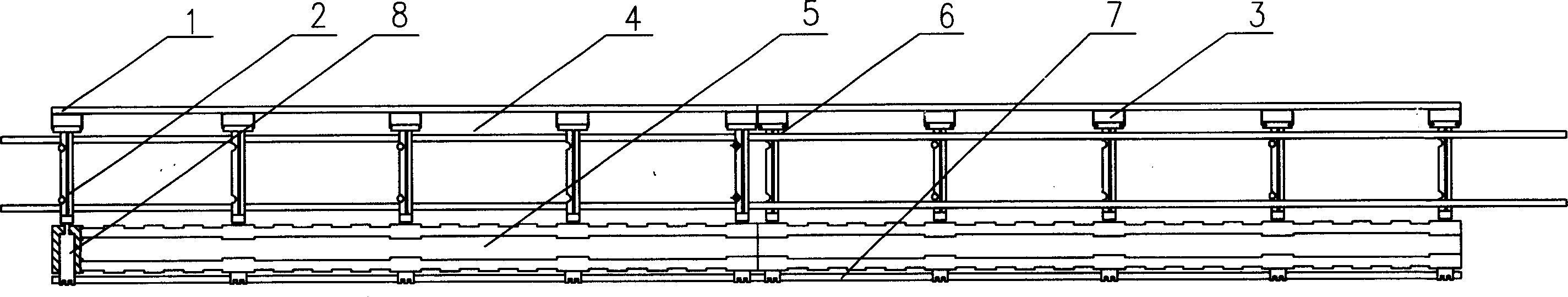

[0060] Embodiment two, see image 3 , 4 , the figure shows an on-site assembled building formwork net with an insulating layer, which includes an expanded metal mesh 1 arranged on the inner side and a crack-limiting mesh 7 arranged face to face with the expanded metal mesh 1 , inside the expanded steel mesh 1 A reinforcing rib 3 is provided; a thermal insulation board 5 is arranged in the crack-limiting net 7, and the connector 2 connects the expanded steel mesh 1 and the crack-limiting net 7 at a certain distance; the connector 2 and the installation The thermal insulation board 5 of the limited crack net 7 and the expanded steel mesh 1 inside are plugged together.

[0061] Among them, see Figure 7 , the inner side of the reinforcing rib 3 has a notch 31 for receiving the connecting piece 2. In this embodiment, the reinforcing rib 3 has a cross section of Shaped C-shaped reinforcing rib, two flat wings 32 are provided on the opening side, and along the longitudinal direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com