Electric rheologic composite laminated rubber bases

A composite lamination and rubber bearing technology, which is applied to building components, shock absorbers, shockproof, etc. Super high-rise buildings are not suitable for problems such as improving the scope of application, simple structure, favorable effects of processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation method of the present invention will be further described below in conjunction with the accompanying drawings:

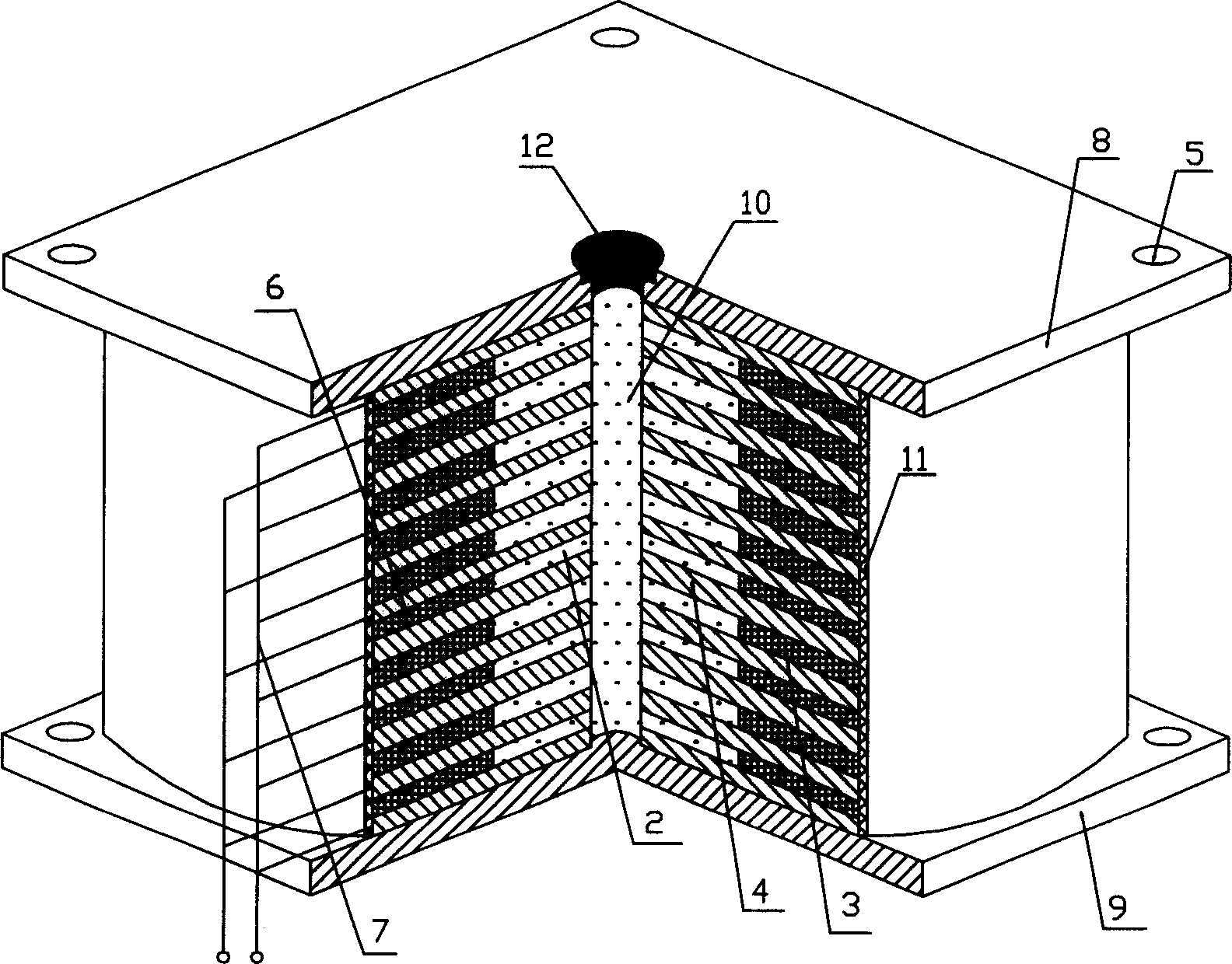

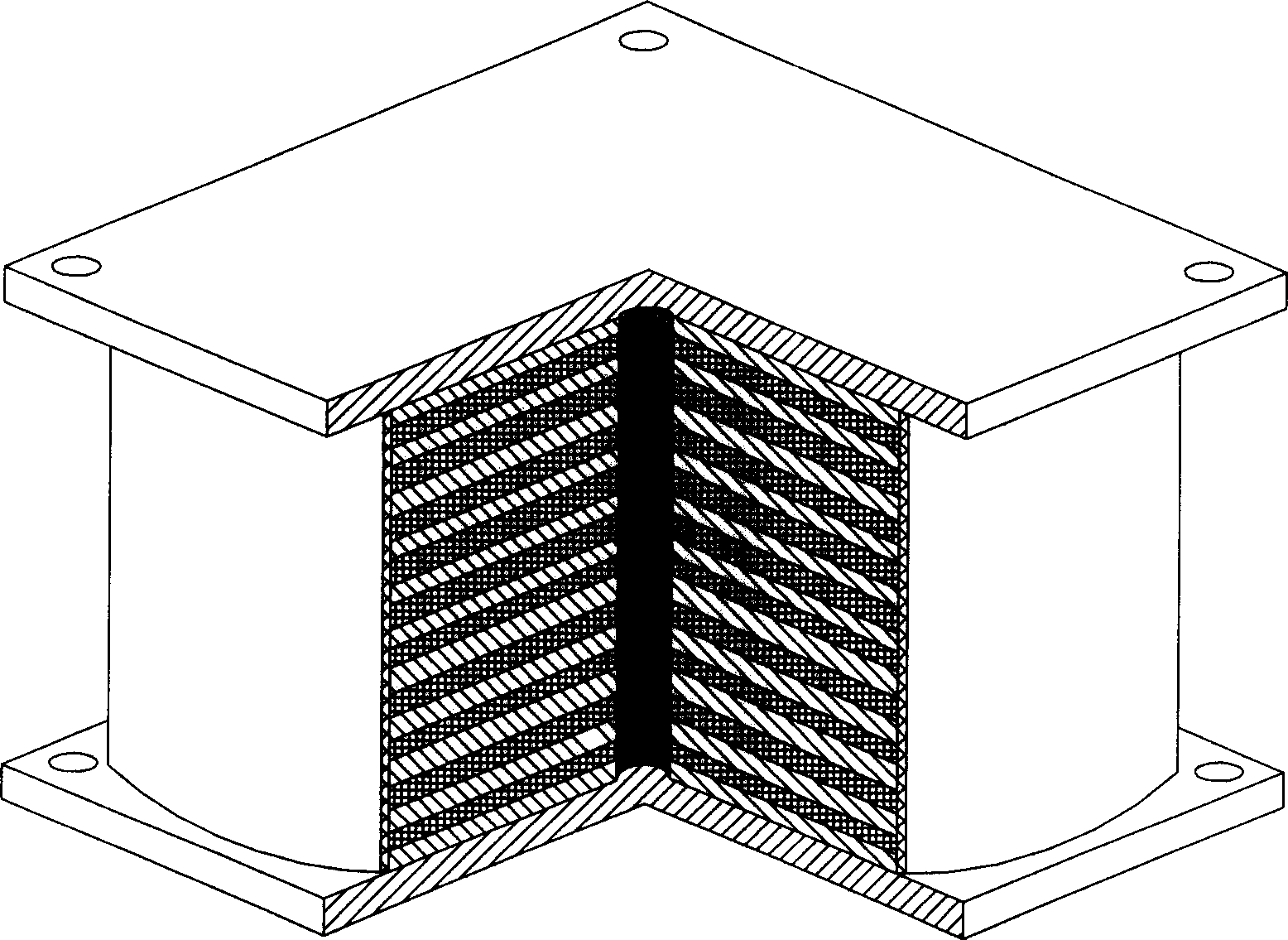

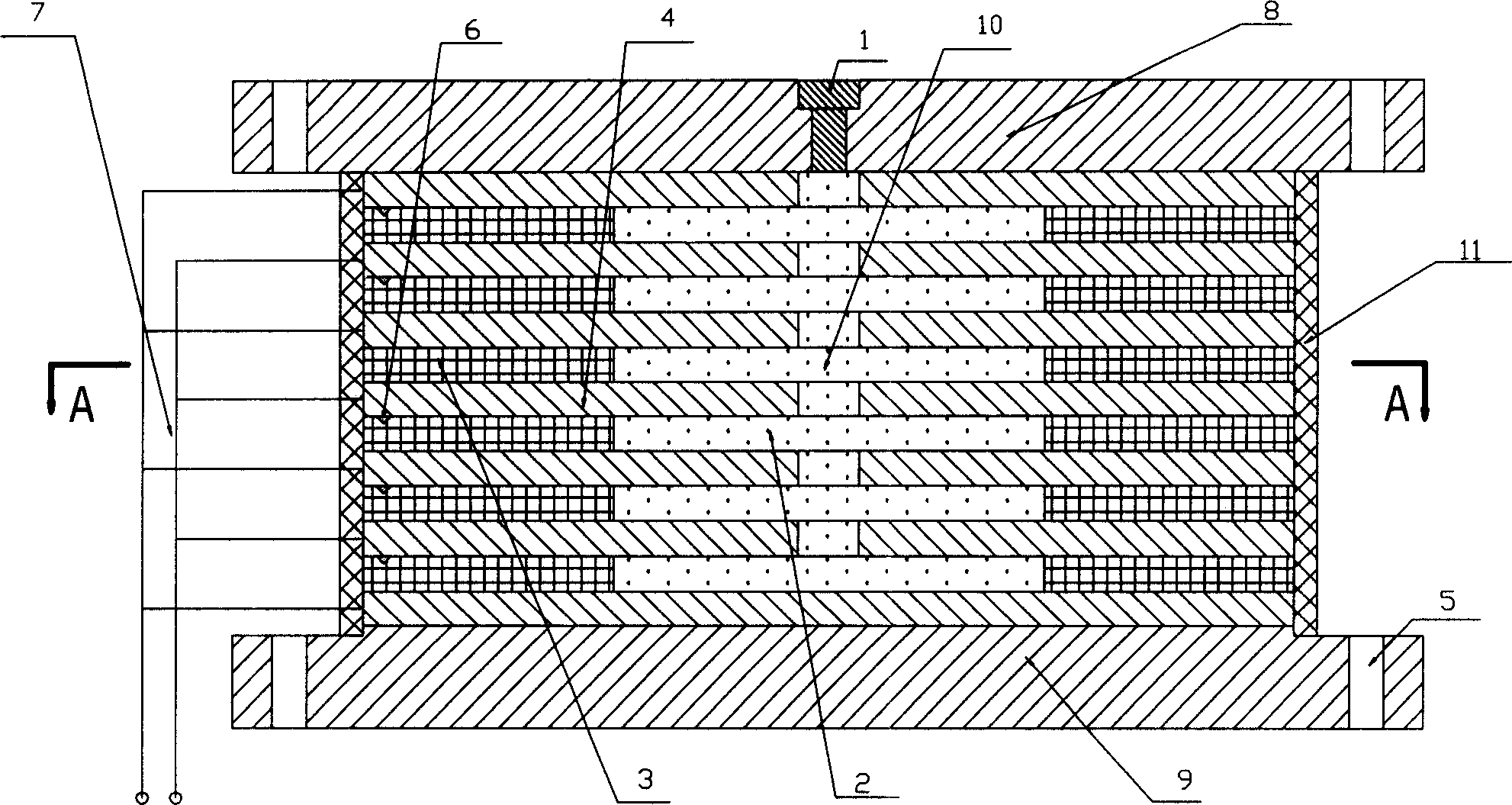

[0021] Such as figure 1 As shown, an electrorheological laminated rubber bearing has the same appearance as the existing laminated rubber bearing but has a unique electrorheological structure inside. A through hole 10 is provided in the center of the support, and the rubber plate 3 and the steel plate 4 are stacked together layer by layer, and the bonding method is the same as that of the prior art. The difference is that part of the rubber in the middle part of the rubber plate 3 is removed, so that a space for filling the electrorheological fluid 2 is formed between the steel plate 4 and the rubber plate 3, and the middle part of the upper connecting plate 8 is provided with a liquid injection hole 12 for injecting the electrorheological fluid 2 and The through hole 10 in the middle of the support is connected, and the space surrounded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com