Tester and testing method for high-sensitivity cement thick liquid flowability

A testing device and cement slurry technology, which are applied in the field of high-sensitivity cement slurry fluidity testing devices, can solve problems such as low precision in theoretical research, and achieve high sensitivity, simple device fabrication and testing operations, and strong repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Use 32.5P.S cement and naphthalene-based high-efficiency water reducer FDN to prepare cement paste. Each sample uses 500g cement and 2.5g water reducer. Change the amount of water to make the water-cement ratio (weight of water added / weight of cement) from 0.28 to 0.285 , 0.29, 0.295 to 0.30 change slightly, and then use the test device and method of the present invention to test the fluidity of the cement slurry. The steps are:

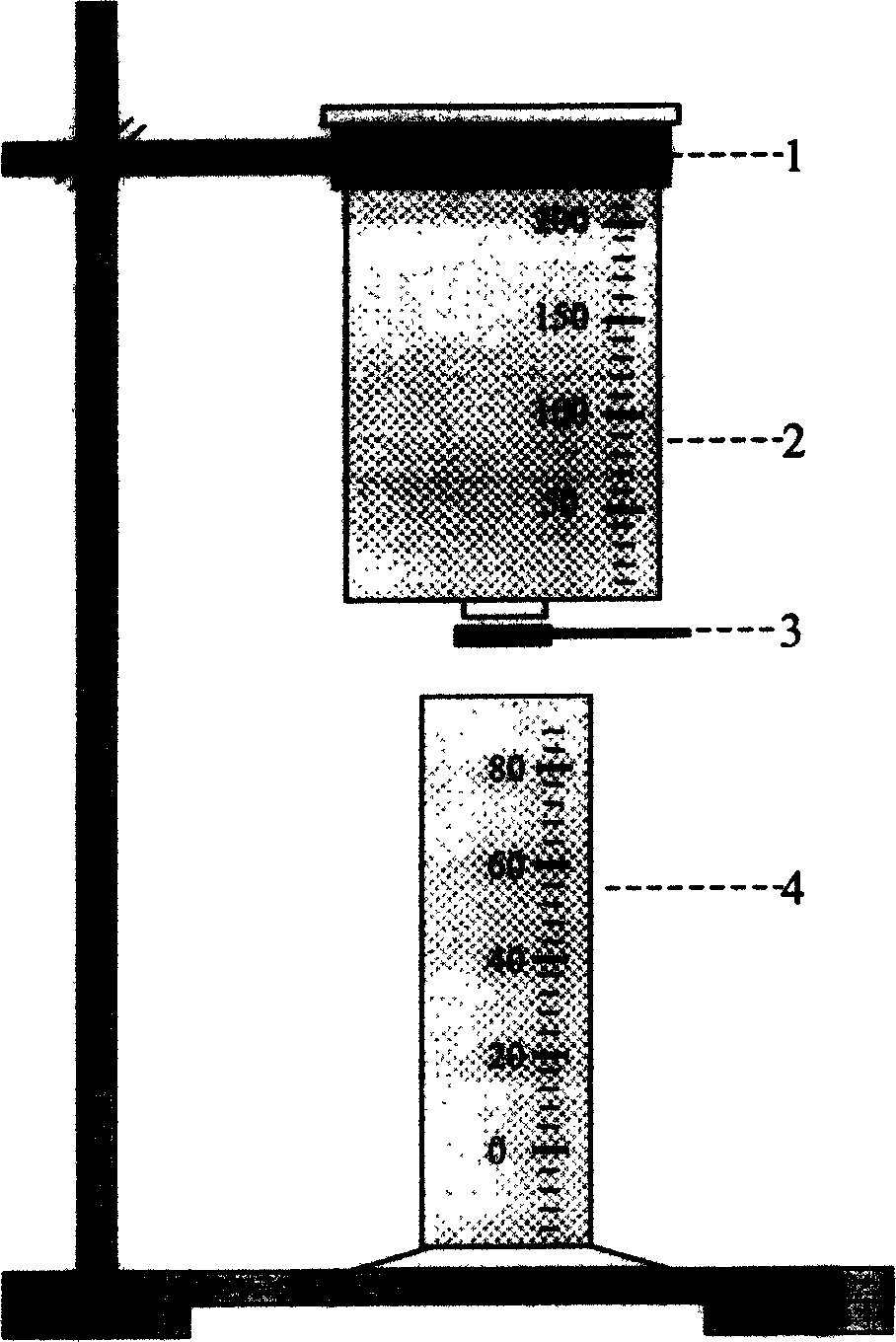

[0021] 1. According to figure 1 As shown, the leaky cylinder 2 is fixed on the fixture of the bracket 1, and the measuring cylinder 4 is placed on the support platform directly below the leaky cylinder;

[0022] 2. Prepare about 150ml of cement slurry according to GB / T1346-2001, plug the small hole at the bottom of the funnel with the cover 3 and pour the slurry into the funnel, then shake it gently for a few times, and let it rest for 5 seconds to make the air bubbles overflow;

[0023] 3. Pull off the cover, let go of the small hole, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com