Optical data storage medium and use of such medium

A storage medium, optical data technology, applied in data recording, information storage, optical record carrier, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

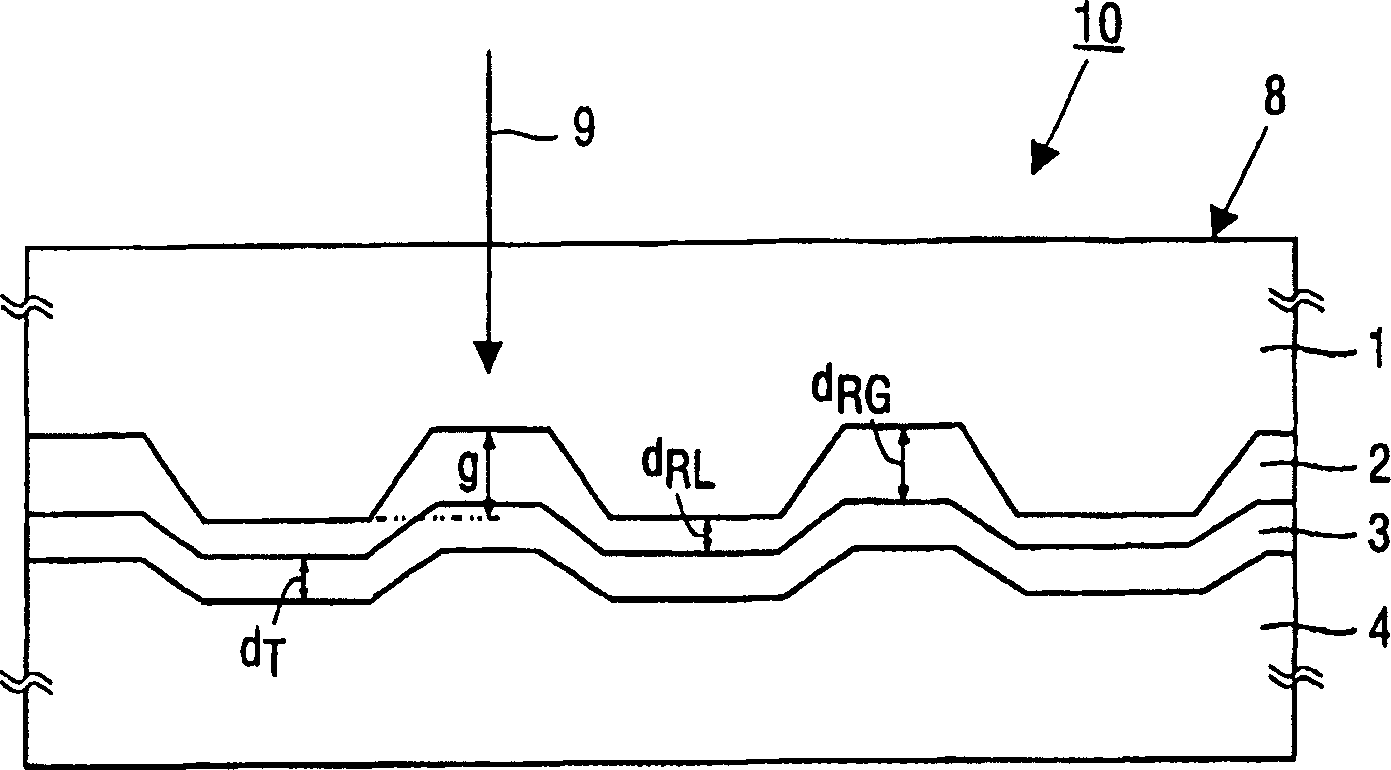

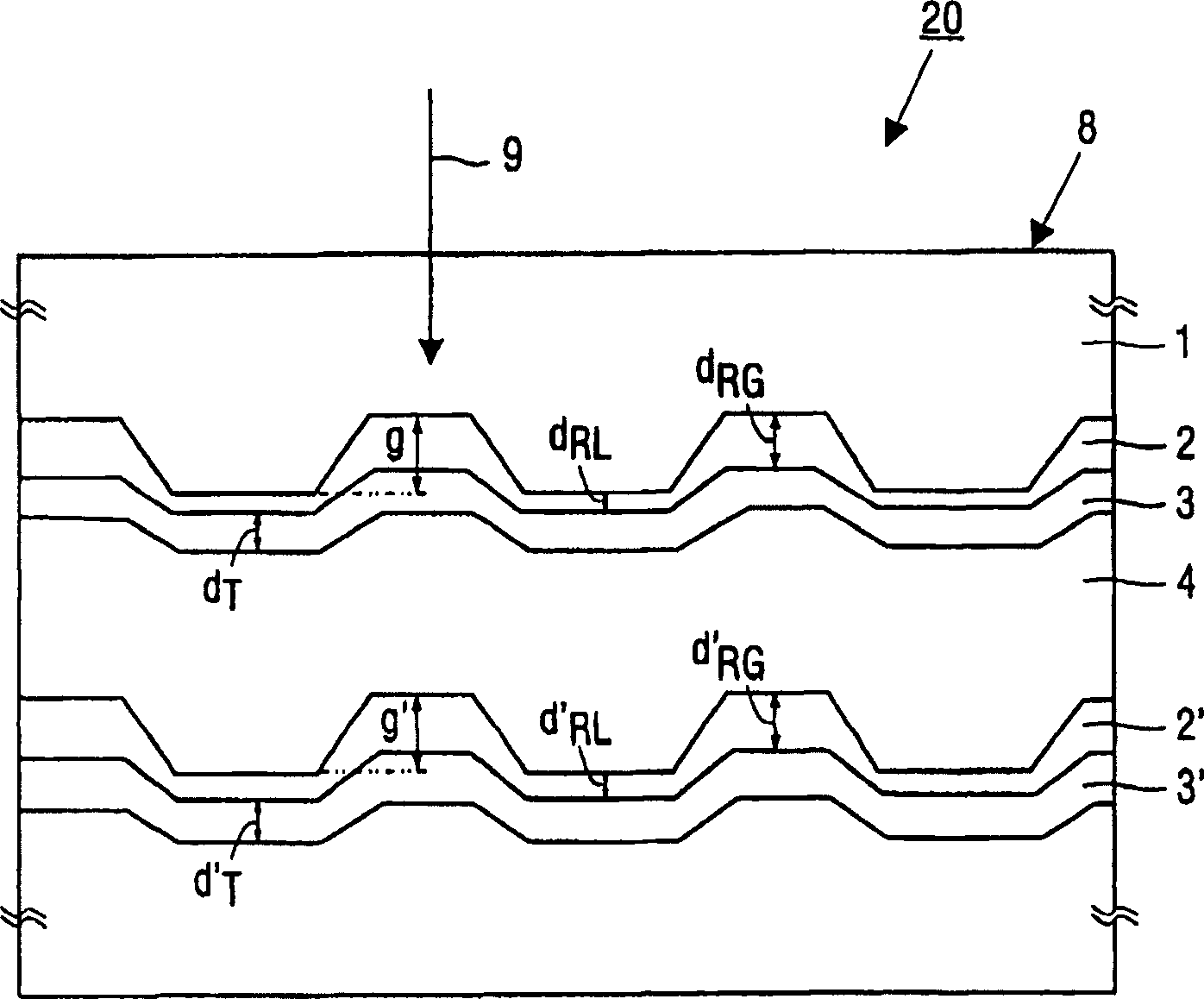

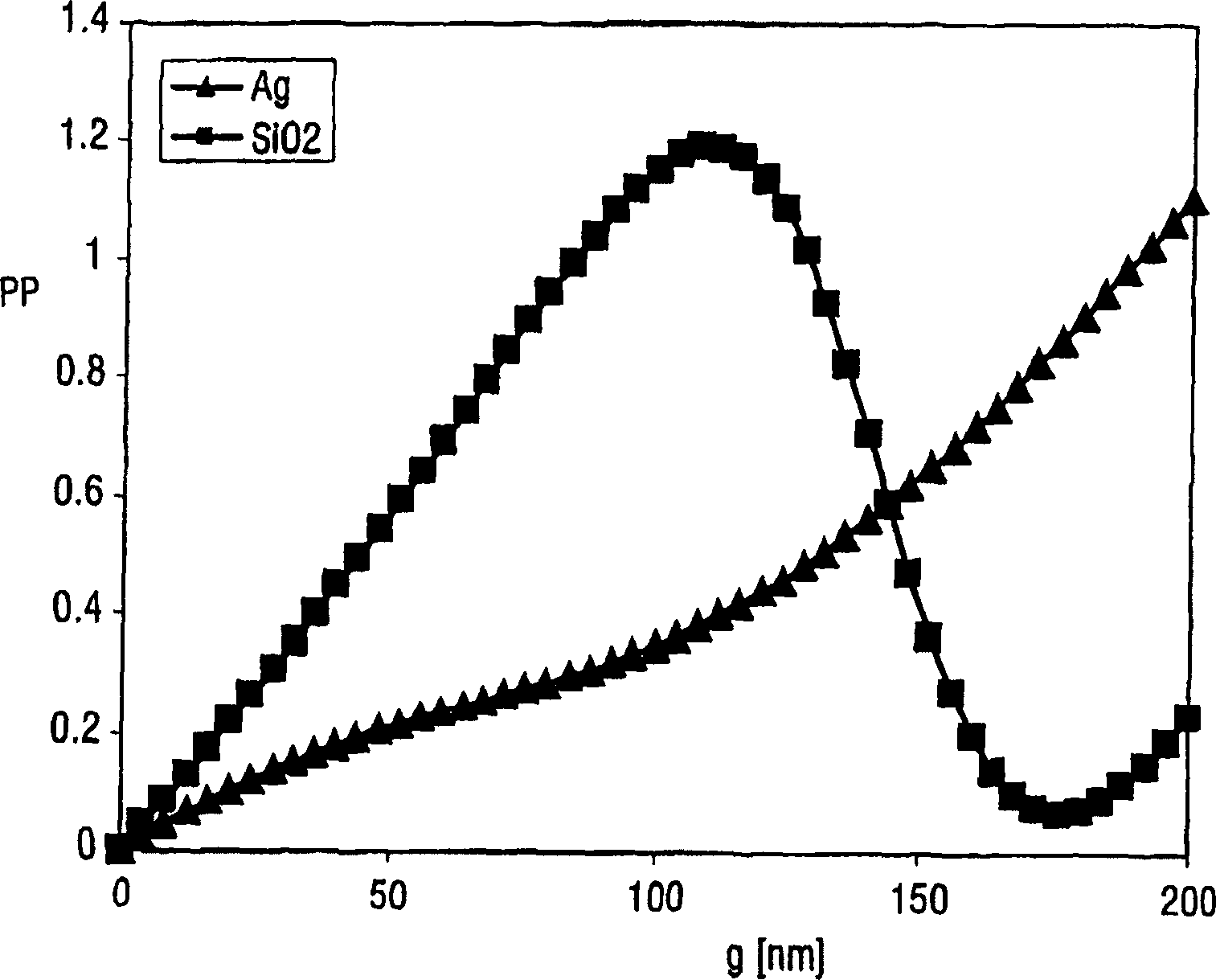

[0038] figure 1 A schematic cross-sectional view of an optical data storage medium 10 according to the invention for recording by means of a focused beam 9 is shown in . The beam is a laser beam with a wavelength [lambda] of approximately 655 nm and which penetrates the entrance face 8 of the medium during recording. The numerical aperture (NA) of the focused beam is 0.65. The medium comprises a base 1 comprising guide grooves of depth g. The guide groove is located on the side of the substrate opposite to the incident surface 8 . The recording stack 2 , 3 in layers is located on the substrate 1 on the side of the guide groove. The recording stack comprises a write-once recording layer 2, given by the complex refractive index at said wavelength n ~ R = 2.45 - i * 0.08 Composed of azo dyes, the thickness of the groove part is d RG =80nm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com