A device for real-time measurement of microscopic stress in optical materials based on single crystal dual electro-optic modulation

A technology of electro-optic modulation and micro-stress, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problems of low modulation amplitude, high cost, phase delay interference, etc., and achieve the effect of satisfying real-time observation, improving sensitivity and eliminating interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

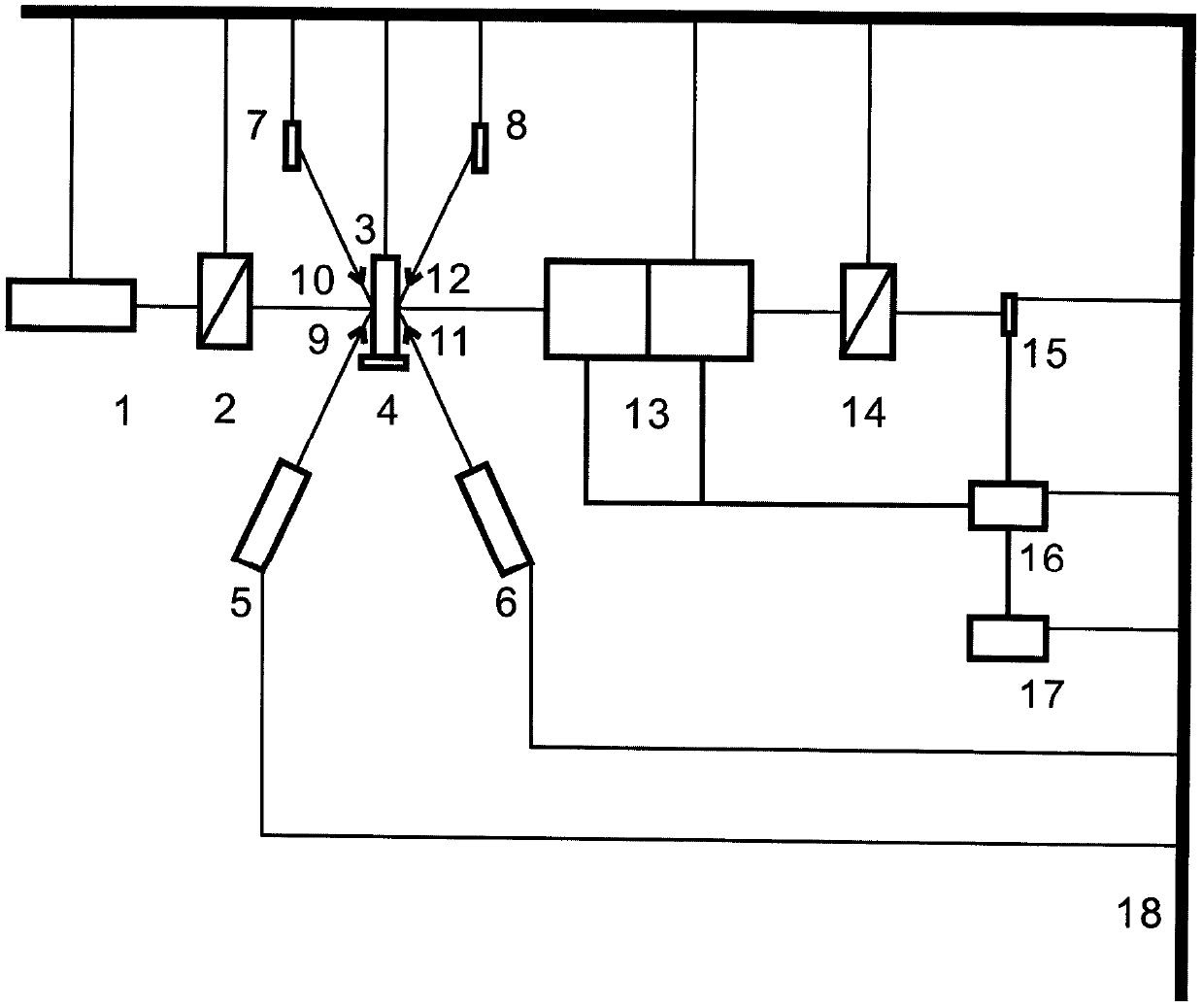

[0083] Design a device based on single crystal dual electro-optic modulation to measure the microscopic stress of optical materials in real time. The extinction ratio of the polarizer and the analyzer is 100000:1, both the polarizer and the analyzer adopt Glan Taylor prisms, the resolution of the electric two-dimensional translation stage is 0.1μm, and the electro-optical modulator has two frequencies ω 1 10kHz, ω 2 It is 30kHz, and the sample is lithium niobate crystal.

Embodiment 2

[0085] Design a device based on single crystal double electro-optic modulation to measure the microscopic stress of optical materials in real time. The extinction ratio of the polarizer and the analyzer is 10000:1, both the polarizer and the analyzer use Glan Taylor prisms, the resolution of the electric two-dimensional translation stage is 0.5μm, and the electro-optical modulator has two frequencies ω 1 1kHz, ω 2 It is 10kHz, and the sample is lithium tantalate crystal.

Embodiment 3

[0087] Design a device based on single crystal double electro-optical modulation to measure the microscopic stress of optical materials in real time. The extinction ratio of the polarizer and the analyzer is 10000:1, the polarizer and the analyzer both use Glan Taylor prisms, the resolution of the electric two-dimensional translation stage is 1 μm, and the electro-optic modulator has two frequencies ω 1 50kHz, ω 2 30kHz, the sample is sapphire crystal.

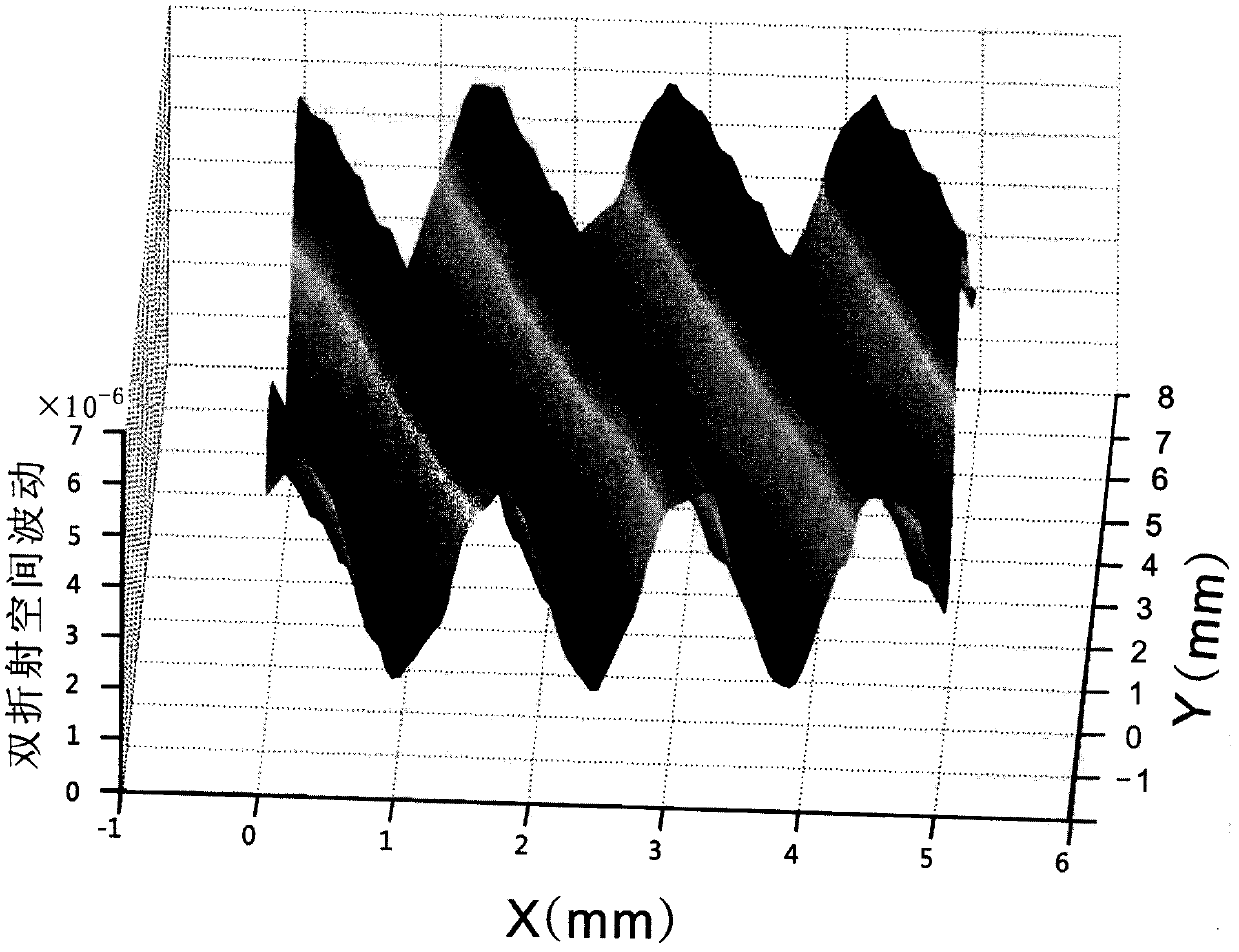

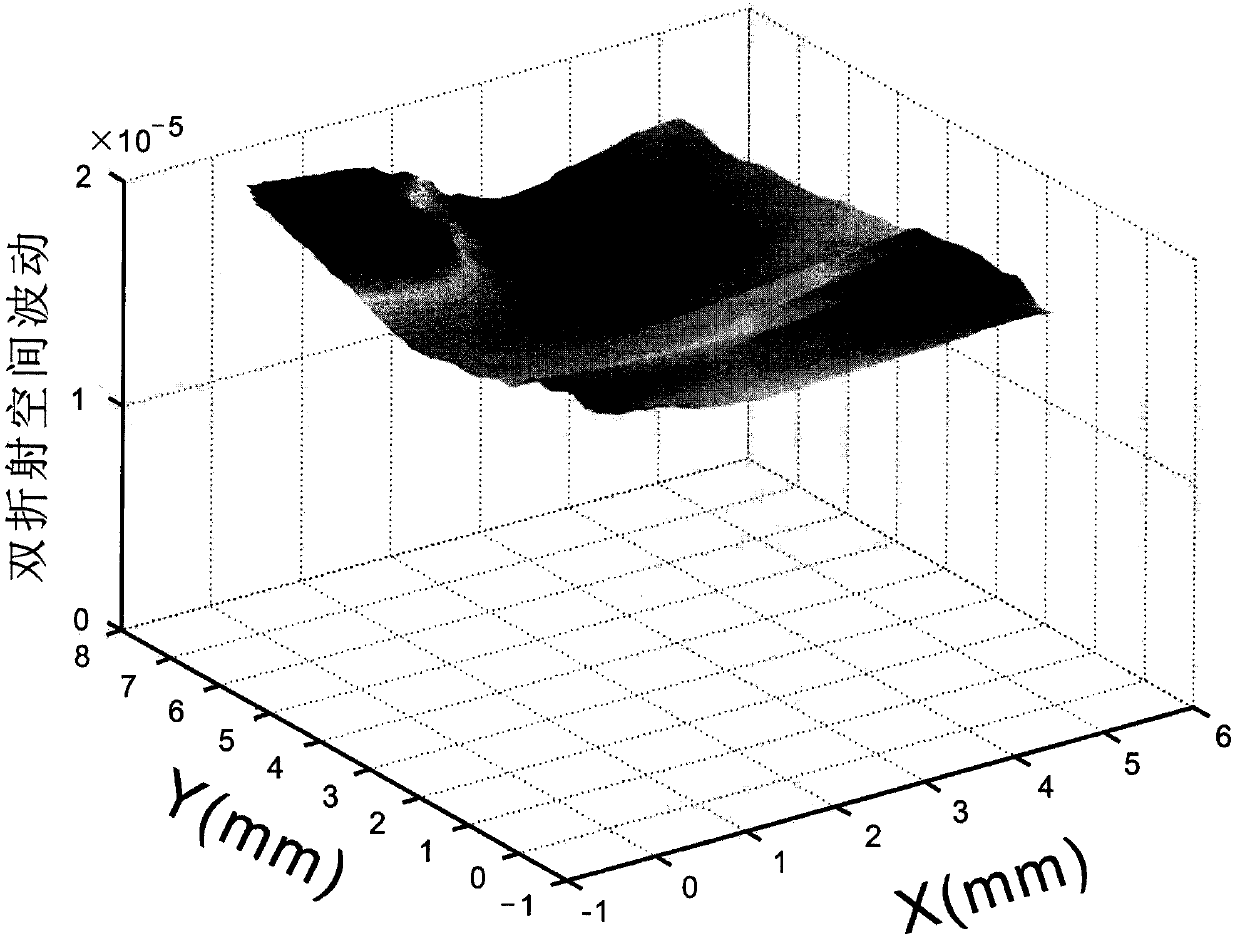

[0088] Utilize detection device of the present invention to carry out microscopic space stress detection (embodiment 1) to lithium niobate crystal, obtain such as Figure 5 The distribution of birefringence spatial fluctuations is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com